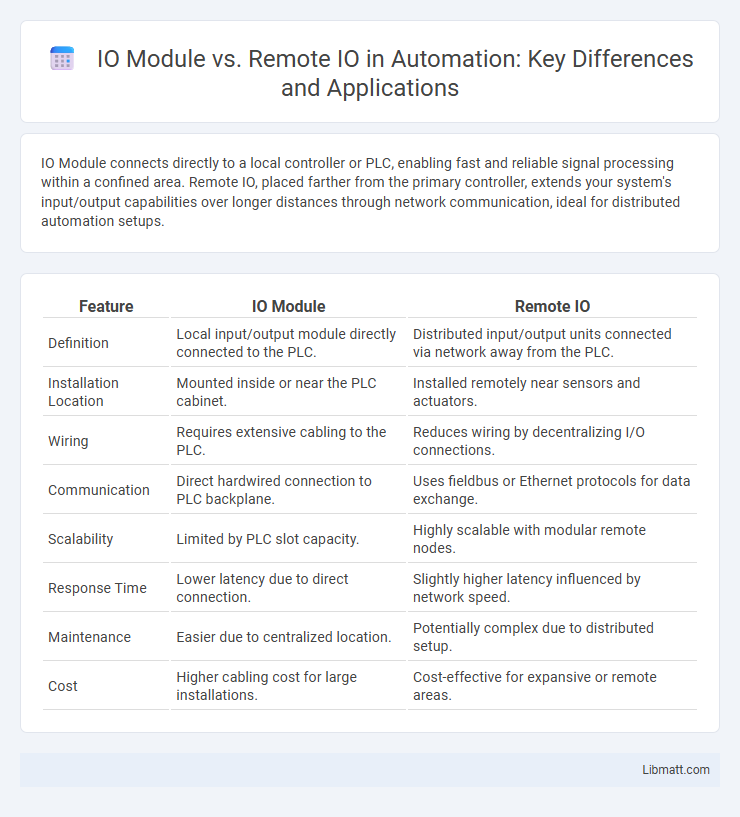

IO Module connects directly to a local controller or PLC, enabling fast and reliable signal processing within a confined area. Remote IO, placed farther from the primary controller, extends your system's input/output capabilities over longer distances through network communication, ideal for distributed automation setups.

Table of Comparison

| Feature | IO Module | Remote IO |

|---|---|---|

| Definition | Local input/output module directly connected to the PLC. | Distributed input/output units connected via network away from the PLC. |

| Installation Location | Mounted inside or near the PLC cabinet. | Installed remotely near sensors and actuators. |

| Wiring | Requires extensive cabling to the PLC. | Reduces wiring by decentralizing I/O connections. |

| Communication | Direct hardwired connection to PLC backplane. | Uses fieldbus or Ethernet protocols for data exchange. |

| Scalability | Limited by PLC slot capacity. | Highly scalable with modular remote nodes. |

| Response Time | Lower latency due to direct connection. | Slightly higher latency influenced by network speed. |

| Maintenance | Easier due to centralized location. | Potentially complex due to distributed setup. |

| Cost | Higher cabling cost for large installations. | Cost-effective for expansive or remote areas. |

Introduction to IO Modules and Remote IO

IO Modules serve as essential interfaces for connecting sensors and actuators to a control system, facilitating direct data acquisition and command execution. Remote IO extends this functionality by allowing these modules to be installed at a distance from the central processor, enhancing system scalability and reducing wiring complexity. Your control infrastructure benefits from improved flexibility and optimized performance through the strategic use of IO Modules and Remote IO solutions.

Key Differences Between IO Module and Remote IO

IO Modules are typically installed directly on the control panel, offering faster data processing and lower latency, whereas Remote IO devices are placed remotely closer to field equipment to reduce wiring costs and improve scalability. IO Modules connect locally to a PLC or DCS, while Remote IO systems communicate over networks such as Ethernet or PROFIBUS, enabling distributed control architecture. Your choice depends on factors like system layout, distance, and flexibility requirements in industrial automation.

Functional Overview: IO Module vs Remote IO

IO Modules are hardware components integrated directly into a control system to facilitate the input and output of analog and digital signals for localized process control. Remote IO systems extend this functionality by decentralizing I/O points away from the main controller, enabling communication over industrial networks such as Ethernet/IP or PROFIBUS for distributed automation. Both IO Modules and Remote IO enhance system scalability and flexibility, with Remote IO offering improved cable management and reduced wiring complexity in large-scale industrial environments.

System Architecture Impact

IO Modules are typically integrated directly into a central controller, resulting in reduced wiring complexity and faster response times in system architecture. Remote IO devices extend input/output capabilities by being physically distributed across a network, enhancing scalability and flexibility while potentially introducing latency. Your system design choice influences communication protocols, installation costs, and maintenance strategies, shaping overall operational efficiency.

Communication Protocols Compared

IO Modules and Remote IO systems differ significantly in their communication protocols, which impact data transfer efficiency and system integration. IO Modules typically use protocols like Modbus, PROFIBUS, or DeviceNet for local control, while Remote IO often relies on Ethernet-based protocols such as EtherNet/IP, PROFINET, or EtherCAT, offering greater speed and scalability. Your choice depends on the required response time, network complexity, and compatibility with existing automation infrastructure.

Installation and Scalability Considerations

IO Modules offer straightforward installation within control panels, enabling compact setups with direct device connectivity, but their scalability is often limited by available slots and wiring complexity. Remote IO systems facilitate flexible installation by distributing IO units closer to field devices, reducing wiring costs and expanding scalability through networked connections. This decentralized approach supports easier expansion and maintenance in large or geographically dispersed industrial environments.

Performance and Response Time

IO Modules typically offer faster performance and lower response times due to their direct integration with the main controller, ensuring minimal latency in data processing. Remote IO systems introduce additional communication layers, which can increase latency but provide scalability and flexibility for distributed applications. Assess Your system's requirements to balance the need for rapid response with the benefits of remote accessibility.

Cost Efficiency: IO Module vs Remote IO

IO Modules generally offer cost efficiency for localized control systems by reducing installation complexity and wiring expenses. Remote IO systems, while potentially more expensive upfront due to communication infrastructure, provide scalable and flexible solutions that lower long-term maintenance and expansion costs. Your choice depends on balancing initial investment against future operational savings and system size.

Common Application Scenarios

IO Modules are typically used for local machine control where direct, high-speed communication with sensors and actuators is essential, often within a confined industrial environment. Remote IO systems excel in distributed applications requiring extended distances between the central controller and field devices, such as large-scale automation in manufacturing plants or process industries. Your choice depends on whether centralized control or wide-area device management better suits your operational topology and communication needs.

Selecting the Right Solution for Your System

Choosing between an IO Module and Remote IO depends on your system's scalability, wiring complexity, and performance requirements. IO Modules are ideal for compact control panels with short-distance connections, offering ease of installation and centralized diagnostics. Remote IO suits distributed systems needing extended cable runs and modular expansion, enabling flexible placement close to field devices to reduce wiring costs and improve maintenance efficiency.

IO Module vs Remote IO Infographic

libmatt.com

libmatt.com