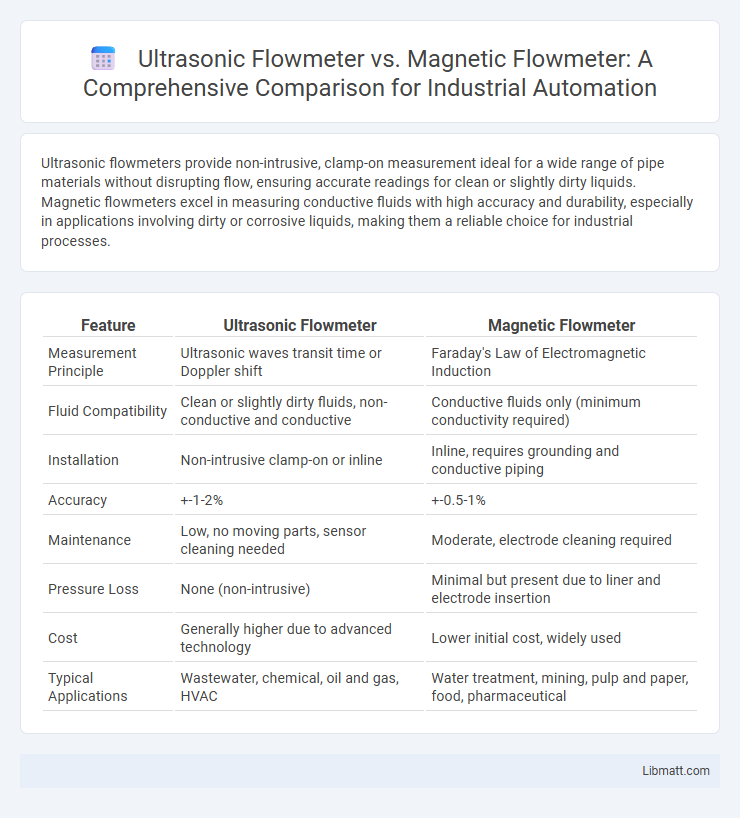

Ultrasonic flowmeters provide non-intrusive, clamp-on measurement ideal for a wide range of pipe materials without disrupting flow, ensuring accurate readings for clean or slightly dirty liquids. Magnetic flowmeters excel in measuring conductive fluids with high accuracy and durability, especially in applications involving dirty or corrosive liquids, making them a reliable choice for industrial processes.

Table of Comparison

| Feature | Ultrasonic Flowmeter | Magnetic Flowmeter |

|---|---|---|

| Measurement Principle | Ultrasonic waves transit time or Doppler shift | Faraday's Law of Electromagnetic Induction |

| Fluid Compatibility | Clean or slightly dirty fluids, non-conductive and conductive | Conductive fluids only (minimum conductivity required) |

| Installation | Non-intrusive clamp-on or inline | Inline, requires grounding and conductive piping |

| Accuracy | +-1-2% | +-0.5-1% |

| Maintenance | Low, no moving parts, sensor cleaning needed | Moderate, electrode cleaning required |

| Pressure Loss | None (non-intrusive) | Minimal but present due to liner and electrode insertion |

| Cost | Generally higher due to advanced technology | Lower initial cost, widely used |

| Typical Applications | Wastewater, chemical, oil and gas, HVAC | Water treatment, mining, pulp and paper, food, pharmaceutical |

Introduction to Flow Measurement Technologies

Ultrasonic flowmeters use high-frequency sound waves to measure the velocity of fluid flow, offering non-intrusive, clamp-on installation that preserves pipe integrity and minimizes maintenance. Magnetic flowmeters operate based on Faraday's law of electromagnetic induction, generating voltage signals proportional to the flow velocity of conductive fluids, ideal for wastewater, slurry, and corrosive liquid applications. Both technologies provide accurate flow measurement, but selection depends on fluid properties, installation constraints, and required precision.

What is an Ultrasonic Flowmeter?

An Ultrasonic Flowmeter measures fluid velocity by sending ultrasonic pulses through the fluid and detecting the transit time difference between upstream and downstream signals. This non-intrusive method offers high accuracy for clean and dirty liquids without pressure loss or contact with the fluid. Ultrasonic Flowmeters are ideal for applications requiring maintenance-free operation and real-time flow measurement in water treatment, chemical, and oil industries.

What is a Magnetic Flowmeter?

A magnetic flowmeter measures the flow rate of conductive liquids by detecting the voltage generated when the fluid moves through a magnetic field, based on Faraday's Law of Electromagnetic Induction. Unlike ultrasonic flowmeters that use sound waves, magnetic flowmeters require the fluid to have a minimum level of electrical conductivity, making them ideal for applications involving water, slurries, or corrosive fluids. Your choice between these devices depends on the specific characteristics of the fluid and the accuracy needed for the measurement.

Key Working Principles Compared

Ultrasonic flowmeters measure fluid velocity by transmitting and receiving high-frequency sound waves through the liquid, calculating flow based on the time difference or frequency shift between signals. Magnetic flowmeters use Faraday's law of electromagnetic induction, detecting voltage generated as conductive fluid passes through a magnetic field to determine flow rate. Both methods provide non-intrusive measurement but differ fundamentally in relying on acoustic versus electromagnetic interactions with the fluid.

Installation Requirements and Setup

Ultrasonic flowmeters require clean pipe surfaces and proper alignment of transducers to ensure accurate measurement, typically involving clamp-on or inline installation without disrupting the flow. Magnetic flowmeters demand conductive fluids and a full pipe for installation, with electrodes embedded in the pipe liner to measure flow via electromagnetic induction, often necessitating grounding rings and insulated pipe sections. Your choice depends on the fluid type, pipe condition, and ease of installation, with ultrasonic flowmeters offering non-intrusive setup and magnetic flowmeters requiring more comprehensive piping modifications.

Accuracy and Performance Differences

Ultrasonic flowmeters use sound waves to measure fluid velocity, offering high accuracy in clean or slightly contaminated liquids, with minimal maintenance due to non-intrusive sensors. Magnetic flowmeters provide superior accuracy and stability in measuring conductive fluids, unaffected by fluid density or temperature changes, and excel in handling slurry or corrosive applications. Performance differences highlight ultrasonic meters as ideal for diverse pipe sizes and non-conductive fluids, while magnetic flowmeters deliver consistent precision in industrial processes requiring robust flow measurement of conductive liquids.

Suitable Applications and Industries

Ultrasonic flowmeters excel in non-invasive measurement of liquids in industries such as water treatment, chemical processing, and HVAC systems, where pipe modification is impractical. Magnetic flowmeters are ideal for conductive fluids in wastewater management, mining, and pulp and paper industries, offering high accuracy in abrasive or corrosive conditions. Your choice depends on fluid conductivity and installation requirements, ensuring optimal flow measurement performance.

Advantages and Limitations of Each Type

Ultrasonic flowmeters offer advantages like non-intrusive installation, no pressure drop, and suitability for both conductive and non-conductive fluids, but they may face challenges with dirty or aerated fluids causing signal attenuation. Magnetic flowmeters excel in measuring conductive liquids with high accuracy, minimal maintenance, and no moving parts, yet they require a fully filled pipe and cannot measure non-conductive fluids. Understanding these differences helps you select the right flowmeter based on your fluid type, installation environment, and measurement accuracy needs.

Cost Considerations and Maintenance

Ultrasonic flowmeters generally have higher upfront costs but require minimal maintenance due to their non-intrusive design with no moving parts, making them cost-effective over time. Magnetic flowmeters usually present lower initial expenses but demand regular maintenance to prevent electrode fouling and ensure accurate measurements, impacting long-term operational costs. Your choice should consider both initial budget constraints and ongoing maintenance capabilities for optimal cost efficiency.

Choosing the Right Flowmeter: Factors to Consider

Selecting the right flowmeter depends on factors such as the type of fluid, pipe material, and installation environment. Ultrasonic flowmeters excel in measuring clean or slightly contaminated liquids without contact, making them ideal for non-intrusive and maintenance-free applications. Magnetic flowmeters are best suited for conductive fluids and offer high accuracy with abrasive or corrosive liquids, ensuring reliable performance in industrial processes where your flow measurement needs precision and durability.

Ultrasonic Flowmeter vs Magnetic Flowmeter Infographic

libmatt.com

libmatt.com