ProfIsafe and CIP Safety are industrial communication protocols designed to ensure functional safety in automation systems, with ProfIsafe operating over PROFINET and PROFIBUS networks while CIP Safety runs on EtherNet/IP and DeviceNet. Choosing between them depends on your existing network infrastructure and specific safety requirements, as both provide reliable real-time safety data transmission for critical applications.

Table of Comparison

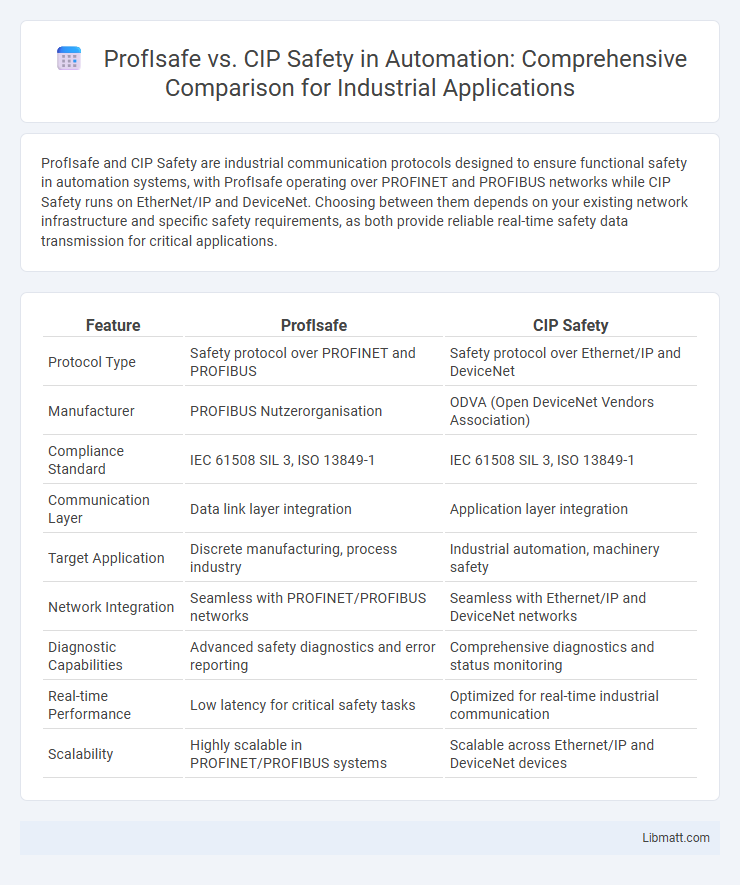

| Feature | ProfIsafe | CIP Safety |

|---|---|---|

| Protocol Type | Safety protocol over PROFINET and PROFIBUS | Safety protocol over Ethernet/IP and DeviceNet |

| Manufacturer | PROFIBUS Nutzerorganisation | ODVA (Open DeviceNet Vendors Association) |

| Compliance Standard | IEC 61508 SIL 3, ISO 13849-1 | IEC 61508 SIL 3, ISO 13849-1 |

| Communication Layer | Data link layer integration | Application layer integration |

| Target Application | Discrete manufacturing, process industry | Industrial automation, machinery safety |

| Network Integration | Seamless with PROFINET/PROFIBUS networks | Seamless with Ethernet/IP and DeviceNet networks |

| Diagnostic Capabilities | Advanced safety diagnostics and error reporting | Comprehensive diagnostics and status monitoring |

| Real-time Performance | Low latency for critical safety tasks | Optimized for real-time industrial communication |

| Scalability | Highly scalable in PROFINET/PROFIBUS systems | Scalable across Ethernet/IP and DeviceNet devices |

Overview of ProfIsafe and CIP Safety

ProfIsafe is a safety communication protocol designed for industrial Ethernet networks, enabling safe and reliable data transfer for automation systems with SIL 3 safety integrity level. CIP Safety is an extension of the Common Industrial Protocol, providing safety communication on Ethernet/IP networks to ensure functional safety in control systems. Both protocols achieve safety through redundant data transmission and strict message validation, supporting real-time monitoring and error detection in complex industrial environments.

Key Features Comparison

ProfIsafe and CIP Safety both provide advanced safety communication protocols for industrial automation but differ in architecture and integration. ProfIsafe operates over PROFIBUS and PROFINET networks, offering comprehensive diagnostic capabilities, user-friendly integration with standard automation tools, and a proven track record in process industries. CIP Safety leverages the Common Industrial Protocol (CIP) over Ethernet/IP networks, delivering flexible device interoperability, real-time safety data exchange, and broad support across Rockwell Automation platforms and multiple vendor ecosystems.

Communication Protocols

ProfIsafe operates as a safety protocol layered on top of Profibus or Profinet networks, ensuring real-time communication and safe data transmission by utilizing cyclic data monitoring and time-stamped safety messages. CIP Safety integrates with Ethernet/IP and DeviceNet, embedding safety information within standard CIP messages, enabling seamless safety communication without requiring a separate network. Both protocols prioritize deterministic and fail-safe communication, but ProfIsafe specializes in industrial automation environments with high-speed cyclic data exchange, while CIP Safety emphasizes compatibility with commercially widespread CIP-based industrial networks.

Integration with Industrial Networks

ProfIsafe integrates seamlessly with the PROFINET and PROFIBUS industrial networks, enabling robust safety communication within Siemens and compatible automation systems. CIP Safety operates natively over EtherNet/IP and DeviceNet networks, providing efficient safety data exchange for Rockwell Automation environments and other ODVA-compliant networks. Both protocols offer deterministic safety messaging but differ in their industrial network compatibility, impacting system design and integration choices in safety-critical automation applications.

Safety Certification and Compliance

ProfIsafe and CIP Safety both adhere to international safety standards, with ProfIsafe certified under IEC 61784-3 and IEC 61508 SIL 3, ensuring high integrity for functional safety in industrial automation. CIP Safety complies with IEC 61784-3 and also meets IEC 61508 SIL 3 requirements, enabling safe communication over standard Ethernet/IP networks. Both protocols undergo rigorous third-party certification processes to guarantee reliable performance and compliance in safety-critical applications across manufacturing environments.

Performance and Reliability

ProfIsafe offers high-performance safety communication by enabling fast response times and low latency, ensuring real-time monitoring in industrial automation environments. CIP Safety emphasizes reliability through its integration with the Common Industrial Protocol, supporting robust cyclic data exchange and seamless interoperability with EtherNet/IP networks. Both protocols maintain stringent error detection mechanisms, but ProfIsafe's deterministic messaging provides enhanced predictability crucial for safety-critical applications.

Scalability and Flexibility

ProfIsafe offers superior scalability with support for a wide range of network topologies and extensive device compatibility, making it ideal for complex industrial environments. CIP Safety provides flexibility through its seamless integration with EtherNet/IP and DeviceNet, enabling efficient expansion within existing infrastructures. Your choice depends on whether you prioritize adaptable safety communication across diverse platforms or streamlined scalability within a specific industrial protocol ecosystem.

Ease of Implementation

ProfIsafe offers straightforward integration within existing PROFINET and PROFIBUS networks, leveraging standardized profiles that simplify configuration and diagnostics. CIP Safety, integrated into Ethernet/IP and DeviceNet protocols, provides flexible safety messaging but may require more complex setup due to its broader network compatibility. Both protocols ensure robust safety communication, yet ProfIsafe is often preferred for ease of implementation in PROFIBUS/PROFINET environments due to its streamlined parameterization tools and reduced engineering effort.

Industry Applications

ProfIsafe excels in industries with extensive automation networks such as automotive manufacturing, process automation, and machinery safety systems. CIP Safety is tailored for factory automation sectors including packaging, material handling, and discrete manufacturing, benefiting from its integration with EtherNet/IP protocols. Both protocols ensure real-time safety communication, but ProfIsafe is preferred in complex process industries while CIP Safety aligns with industrial Ethernet environments.

Choosing the Right Safety Protocol

Choosing the right safety protocol between ProfIsafe and CIP Safety depends on system compatibility and network requirements; ProfIsafe is optimized for PROFINET and PROFIBUS systems, offering seamless integration with Siemens environments. CIP Safety excels in EtherNet/IP and DeviceNet networks, providing flexible multi-vendor device support and deterministic safety communication. Evaluating existing infrastructure and long-term scalability ensures selecting a protocol that aligns with operational reliability and compliance standards.

ProfIsafe vs CIP Safety Infographic

libmatt.com

libmatt.com