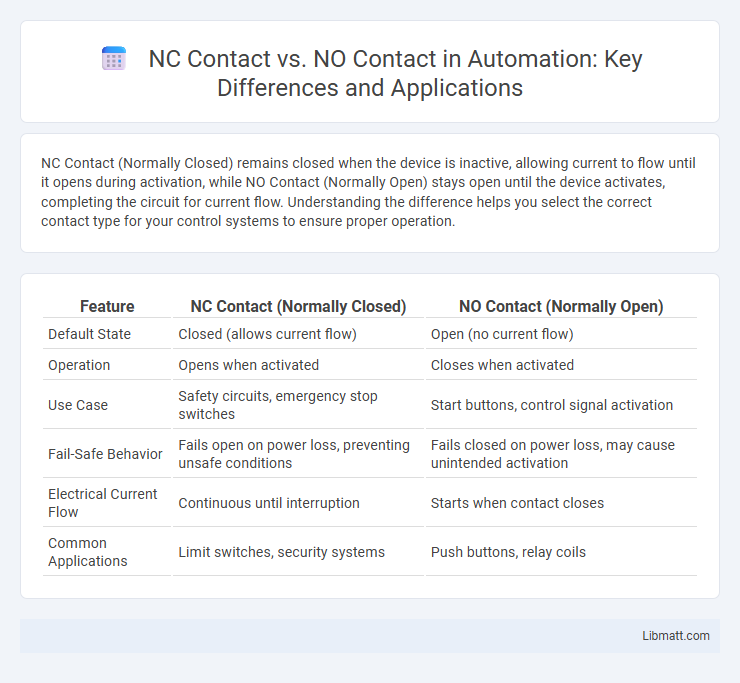

NC Contact (Normally Closed) remains closed when the device is inactive, allowing current to flow until it opens during activation, while NO Contact (Normally Open) stays open until the device activates, completing the circuit for current flow. Understanding the difference helps you select the correct contact type for your control systems to ensure proper operation.

Table of Comparison

| Feature | NC Contact (Normally Closed) | NO Contact (Normally Open) |

|---|---|---|

| Default State | Closed (allows current flow) | Open (no current flow) |

| Operation | Opens when activated | Closes when activated |

| Use Case | Safety circuits, emergency stop switches | Start buttons, control signal activation |

| Fail-Safe Behavior | Fails open on power loss, preventing unsafe conditions | Fails closed on power loss, may cause unintended activation |

| Electrical Current Flow | Continuous until interruption | Starts when contact closes |

| Common Applications | Limit switches, security systems | Push buttons, relay coils |

Understanding NC Contact and NO Contact

NC Contact (Normally Closed Contact) remains closed when the device is inactive, allowing current to flow continuously until activated to open the circuit. NO Contact (Normally Open Contact) stays open in its default state, preventing current flow until triggered to close and complete the circuit. Understanding these contact types helps you design control systems that respond correctly to specific operational conditions.

Definitions: What is NC Contact?

NC Contact, or Normally Closed Contact, is an electrical switch contact that remains closed (allowing current flow) in its default state without external actuation. It opens when the switch is activated, interrupting the circuit and stopping the current flow. NC Contacts are commonly used in safety and control systems to ensure circuits are completed unless a specific action triggers a break.

Definitions: What is NO Contact?

NO Contact, or Normally Open Contact, refers to an electrical switch or relay contact that remains open (disconnected) when in its default or unenergized state, preventing current flow. When activated, the contact closes, allowing electrical current to pass through the circuit. This type of contact is commonly used in control systems to initiate actions only when triggered.

Key Differences Between NC Contact and NO Contact

NC Contact (Normally Closed Contact) remains closed in its default state, allowing current to flow, while NO Contact (Normally Open Contact) stays open, preventing current flow until activated. The key difference lies in their default conditions: NC contacts are engaged until interrupted, commonly used in safety or fail-safe circuits, whereas NO contacts require an external trigger to close, ideal for signaling or starting operations. Understanding these distinctions helps optimize your circuit design and control system reliability.

Applications of NC Contact Switches

NC contact switches are widely used in safety and emergency systems where circuits need to remain closed until an action occurs, such as in fire alarm systems and emergency stop buttons in industrial machinery. These switches ensure the loss of contact immediately triggers an alert or shutdown, providing reliable fail-safe operation. Common applications also include security systems, where maintaining continuous circuit monitoring is critical to detect unauthorized access.

Applications of NO Contact Switches

NO (Normally Open) contact switches are widely used in applications requiring circuits to remain open until activated, such as push-button start systems in vehicles, momentary doorbells, and industrial machine controls. These switches play a critical role in safety systems by enabling emergency stop buttons, where the circuit must only close under deliberate user action. The versatility of NO contact switches extends to automation processes, where they initiate sequential operations upon receiving user input or sensor signals.

Advantages and Disadvantages of NC Contact

NC (Normally Closed) contacts ensure a circuit remains closed when inactive, providing immediate fail-safe operation in safety systems. Advantages include consistent power supply and reliability during power loss, but disadvantages involve increased wear due to continuous current flow and potential unwanted activation in fault conditions. NC contacts are essential for emergency stop functions, yet their constant conductivity can lead to higher energy consumption compared to NO (Normally Open) contacts.

Advantages and Disadvantages of NO Contact

NO contact switches offer advantages such as reduced risk of accidental equipment activation or short circuits, as the circuit remains open until the switch is engaged. They are ideal in safety-critical applications where ensuring that power or signals are off by default is crucial. However, disadvantages include potential failure to activate devices when needed and susceptibility to contact wear or corrosion, which can lead to unreliable operation over time.

Common Use Cases in Electrical Circuits

NC contacts are frequently used in safety and fail-safe systems where the default state ensures a circuit remains closed to prevent hazard, such as emergency stop buttons and alarm circuits. NO contacts are common in control and automation systems where the circuit should only be completed upon activation, like push-to-start buttons or indicator lights. Understanding Your application requirements helps determine whether NC or NO contacts best optimize circuit functionality and safety.

How to Choose Between NC and NO Contacts

Choosing between NC (Normally Closed) and NO (Normally Open) contacts depends on the desired default state of an electrical circuit. NC contacts stay closed when the device is unpowered, making them ideal for safety and fail-safe applications where the circuit must remain active during a fault. NO contacts remain open when unpowered, suitable for control systems that activate devices only when powered, ensuring minimal current flow in the default state.

NC Contact vs NO Contact Infographic

libmatt.com

libmatt.com