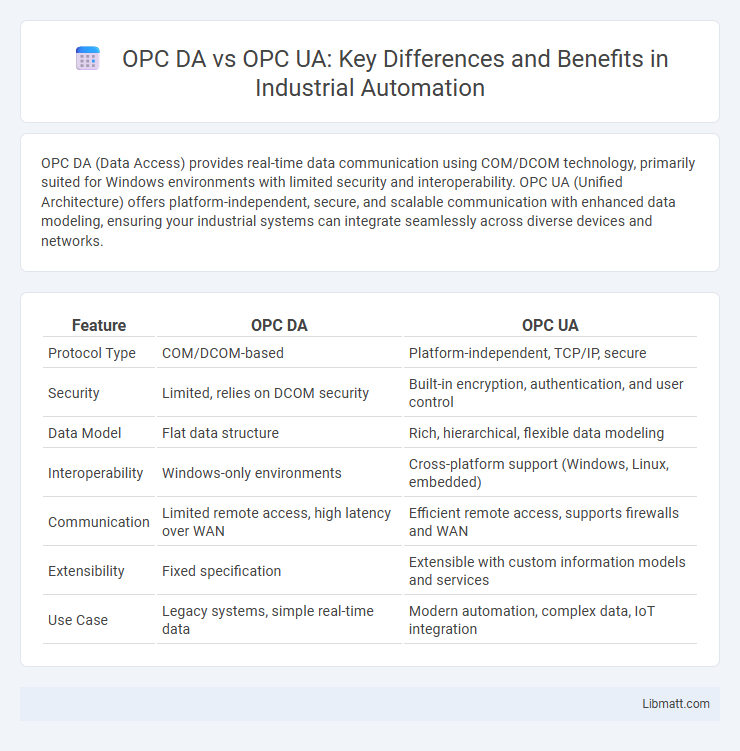

OPC DA (Data Access) provides real-time data communication using COM/DCOM technology, primarily suited for Windows environments with limited security and interoperability. OPC UA (Unified Architecture) offers platform-independent, secure, and scalable communication with enhanced data modeling, ensuring your industrial systems can integrate seamlessly across diverse devices and networks.

Table of Comparison

| Feature | OPC DA | OPC UA |

|---|---|---|

| Protocol Type | COM/DCOM-based | Platform-independent, TCP/IP, secure |

| Security | Limited, relies on DCOM security | Built-in encryption, authentication, and user control |

| Data Model | Flat data structure | Rich, hierarchical, flexible data modeling |

| Interoperability | Windows-only environments | Cross-platform support (Windows, Linux, embedded) |

| Communication | Limited remote access, high latency over WAN | Efficient remote access, supports firewalls and WAN |

| Extensibility | Fixed specification | Extensible with custom information models and services |

| Use Case | Legacy systems, simple real-time data | Modern automation, complex data, IoT integration |

Introduction to OPC DA and OPC UA

OPC DA (Data Access) is a legacy communication protocol primarily designed for real-time data exchange in industrial automation environments, relying on Microsoft's COM/DCOM technology. OPC UA (Unified Architecture) is a modern, platform-independent standard that enhances security, scalability, and interoperability for complex industrial systems through service-oriented architecture and standardized data modeling. Understanding the differences between OPC DA and OPC UA helps you select the right protocol for your industrial communication needs, optimizing data integration and system performance.

Evolution of OPC Standards

OPC DA (Data Access) represents the legacy OPC standard designed for real-time data communication within Windows-based industrial systems, offering limited security and platform dependency. OPC UA (Unified Architecture) evolves the OPC standard by providing a platform-independent, secure, and scalable architecture that supports advanced data modeling, encryption, and interoperability across diverse industrial environments. Understanding this evolution helps optimize Your industrial communication infrastructure with enhanced flexibility and future-proof technology.

Key Differences Between OPC DA and OPC UA

OPC DA (Data Access) operates primarily on COM/DCOM protocols, providing real-time data exchange within local networks, while OPC UA (Unified Architecture) offers platform-independent communication with enhanced security and scalability using TCP/IP and web services. OPC UA supports complex data modeling, encrypted communication, and interoperability across diverse systems, making it suitable for modern industrial IoT applications unlike OPC DA's limited data types and architecture. The transition from OPC DA to OPC UA addresses cybersecurity risks and extends functionality, enabling seamless integration in distributed and cloud-based environments.

Protocol Architecture Comparison

OPC DA (Data Access) operates on a classic COM/DCOM-based architecture, designed for real-time data communication within Windows environments, resulting in limited platform compatibility and security constraints. OPC UA (Unified Architecture) employs a platform-independent, service-oriented architecture (SOA) with built-in security features and supports diverse data models and protocols, enabling seamless interoperability across multiple devices and systems. The OPC UA architecture enhances scalability, robustness, and flexibility through modular design, use of web services, and standard communication stacks such as TCP/IP and HTTPS.

Security Features: OPC DA vs OPC UA

OPC UA offers advanced security features including robust encryption, user authentication, and message integrity, which are essential for protecting industrial data in modern IoT environments. OPC DA, by contrast, lacks inherent security protocols and relies on underlying Windows security, making it vulnerable to unauthorized access and cyber threats. Your choice of OPC UA ensures enhanced protection for sensitive automation data through comprehensive security mechanisms built directly into the protocol.

Platform and Interoperability

OPC DA operates primarily on Microsoft Windows platforms, limiting its compatibility to legacy systems and restricting cross-platform usage. OPC UA offers a platform-independent architecture supporting Windows, Linux, and embedded systems, enhancing interoperability across diverse industrial environments. Your industrial applications benefit from OPC UA's unified framework, enabling seamless communication between heterogeneous devices and increasing integration flexibility.

Data Modeling Capabilities

OPC UA offers advanced data modeling capabilities with support for complex object-oriented structures, enabling seamless integration and standardized representation of data across diverse industrial systems. Unlike OPC DA, which primarily handles raw data points, OPC UA allows you to create detailed information models, enhancing interoperability and context-rich data exchange. This robustness in data modeling makes OPC UA a superior choice for modern industrial automation requiring scalable and flexible data architecture.

Implementation and Integration Challenges

OPC DA relies on legacy COM/DCOM technology, creating challenges with firewall configuration, platform dependence, and security limitations. OPC UA offers platform independence and improved security through standardized web services and binary protocols, easing integration across heterogeneous systems. Your implementation of OPC UA reduces complexity and enhances scalability, but may require more initial setup and familiarity with modern protocols.

Migration Path: From OPC DA to OPC UA

Migrating from OPC DA to OPC UA involves transitioning from a legacy COM-based architecture to a platform-independent, secure, and scalable framework that supports modern industrial IoT standards. Your migration path typically includes implementing OPC UA wrappers or proxies to enable interoperability between existing OPC DA clients and OPC UA servers, followed by gradually replacing OPC DA components with native OPC UA implementations to leverage enhanced data modeling and security features. Careful planning ensures minimal downtime and maximizes the benefits of OPC UA's advanced capabilities for future-proof industrial communication.

Future Trends in Industrial Connectivity

OPC UA is rapidly becoming the industry standard due to its platform independence, enhanced security features, and ability to support complex data models, enabling seamless integration across IT and OT environments. OPC DA, limited to Windows-based systems and legacy data access, is gradually being phased out as industrial connectivity demands evolve towards interoperability and cloud compatibility. Investing in OPC UA ensures your industrial systems remain future-proof, scalable, and ready for advanced applications like IIoT and Industry 4.0.

OPC DA vs OPC UA Infographic

libmatt.com

libmatt.com