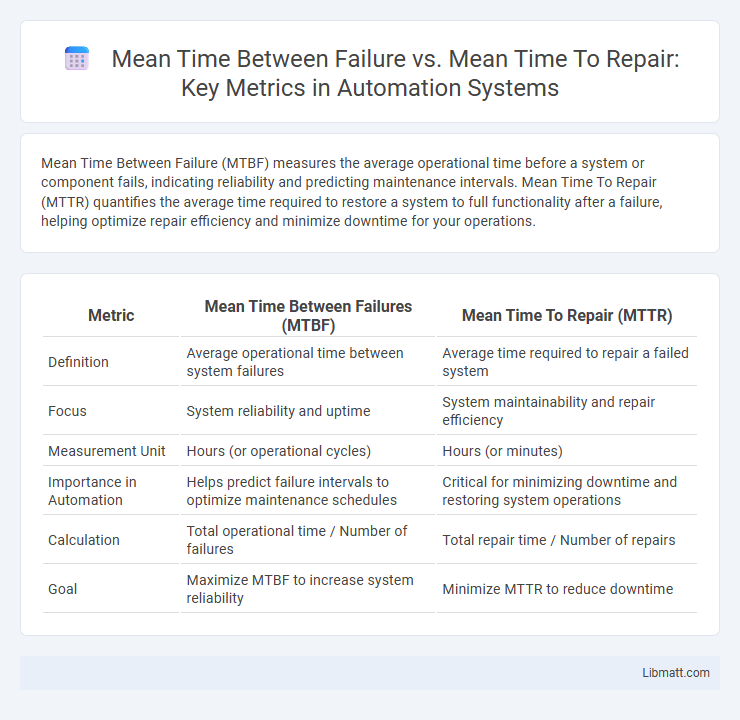

Mean Time Between Failure (MTBF) measures the average operational time before a system or component fails, indicating reliability and predicting maintenance intervals. Mean Time To Repair (MTTR) quantifies the average time required to restore a system to full functionality after a failure, helping optimize repair efficiency and minimize downtime for your operations.

Table of Comparison

| Metric | Mean Time Between Failures (MTBF) | Mean Time To Repair (MTTR) |

|---|---|---|

| Definition | Average operational time between system failures | Average time required to repair a failed system |

| Focus | System reliability and uptime | System maintainability and repair efficiency |

| Measurement Unit | Hours (or operational cycles) | Hours (or minutes) |

| Importance in Automation | Helps predict failure intervals to optimize maintenance schedules | Critical for minimizing downtime and restoring system operations |

| Calculation | Total operational time / Number of failures | Total repair time / Number of repairs |

| Goal | Maximize MTBF to increase system reliability | Minimize MTTR to reduce downtime |

Introduction to MTBF and MTTR

Mean Time Between Failure (MTBF) measures the average operational time between system breakdowns, quantifying reliability and predicting maintenance intervals. Mean Time To Repair (MTTR) indicates the average duration required to restore a failed system to full functionality, reflecting maintenance efficiency. Understanding MTBF and MTTR helps optimize system uptime and maintenance strategies in industrial and IT environments.

Definition of Mean Time Between Failure (MTBF)

Mean Time Between Failure (MTBF) measures the average operational time elapsed between inherent failures of a system during normal usage, serving as a key metric in reliability engineering. It quantifies the expected duration your equipment or system operates before experiencing a failure that requires maintenance or repair. MTBF helps optimize maintenance schedules and improve product life cycles by identifying components with frequent breakdowns.

Understanding Mean Time To Repair (MTTR)

Mean Time To Repair (MTTR) measures the average time required to diagnose, fix, and restore a system or component after a failure. It reflects the efficiency of maintenance processes and directly impacts system availability and operational continuity. Comparing MTTR with Mean Time Between Failure (MTBF) helps organizations balance reliability and repair speed to optimize overall asset performance.

MTBF vs MTTR: Key Differences

Mean Time Between Failure (MTBF) measures the average operational time between system breakdowns, reflecting overall reliability, while Mean Time To Repair (MTTR) quantifies the average duration required to fix a failure and restore functionality. High MTBF values indicate durable and stable systems, whereas low MTTR values demonstrate efficient maintenance and rapid recovery processes. Understanding the relationship between MTBF and MTTR is critical for optimizing equipment availability and minimizing downtime in industrial and IT environments.

Importance of MTBF and MTTR in Reliability Engineering

Mean Time Between Failure (MTBF) measures the average time a system operates before experiencing a failure, serving as a key indicator of reliability and maintenance planning. Mean Time To Repair (MTTR) quantifies the average duration required to restore a system to full functionality after a breakdown, reflecting the efficiency of repair processes. Your ability to optimize both MTBF and MTTR directly impacts operational uptime, cost efficiency, and the overall reliability engineering strategy.

How to Calculate MTBF and MTTR

Mean Time Between Failure (MTBF) is calculated by dividing the total operational time by the number of failures, providing a measure of the average time a system operates before experiencing a failure. Mean Time To Repair (MTTR) is determined by dividing the total downtime caused by failures by the number of repairs, indicating the average time needed to restore a system to working order. Accurate calculation of MTBF and MTTR requires detailed tracking of operational hours and repair durations for each failure event.

Factors Affecting MTBF and MTTR

Factors affecting Mean Time Between Failure (MTBF) include equipment quality, operational conditions, and maintenance practices, as higher-quality components and controlled environments generally extend MTBF. Mean Time To Repair (MTTR) is influenced by the availability of skilled personnel, accessibility of spare parts, and efficiency of repair procedures, which collectively reduce downtime. Your ability to optimize both MTBF and MTTR depends on proactive maintenance planning and resource allocation to enhance system reliability and minimize repair time.

Improving System Reliability with MTBF and MTTR Metrics

Mean Time Between Failure (MTBF) quantifies the average operational time between system failures, while Mean Time To Repair (MTTR) measures the average time required to restore a system after a failure. Optimizing MTBF increases system reliability by extending operational uptime, and reducing MTTR minimizes downtime through faster repairs. Focusing on these metrics helps you identify weaknesses and implement proactive maintenance strategies, ultimately enhancing overall system performance.

Common Mistakes in Interpreting MTBF and MTTR

Confusing Mean Time Between Failure (MTBF) with reliability leads to overestimating system robustness, as MTBF represents average operational time before failure, not guaranteed lifespan. Misinterpreting Mean Time To Repair (MTTR) as downtime duration rather than an average repair time causes inaccurate maintenance scheduling and resource allocation. Understanding that MTBF and MTTR serve different purposes can help you optimize maintenance strategies and improve system availability.

Best Practices for Using MTBF and MTTR in Maintenance Planning

Optimal maintenance planning relies on accurate analysis of Mean Time Between Failure (MTBF) and Mean Time To Repair (MTTR) metrics to enhance equipment reliability and minimize downtime. Integrating MTBF data helps prioritize preventive maintenance schedules based on failure frequency, while MTTR insights streamline repair processes by identifying bottlenecks and resource allocation needs. Consistent monitoring and updating of MTBF and MTTR enable predictive maintenance strategies that reduce unexpected breakdowns and improve overall operational efficiency.

Mean Time Between Failure vs Mean Time To Repair Infographic

libmatt.com

libmatt.com