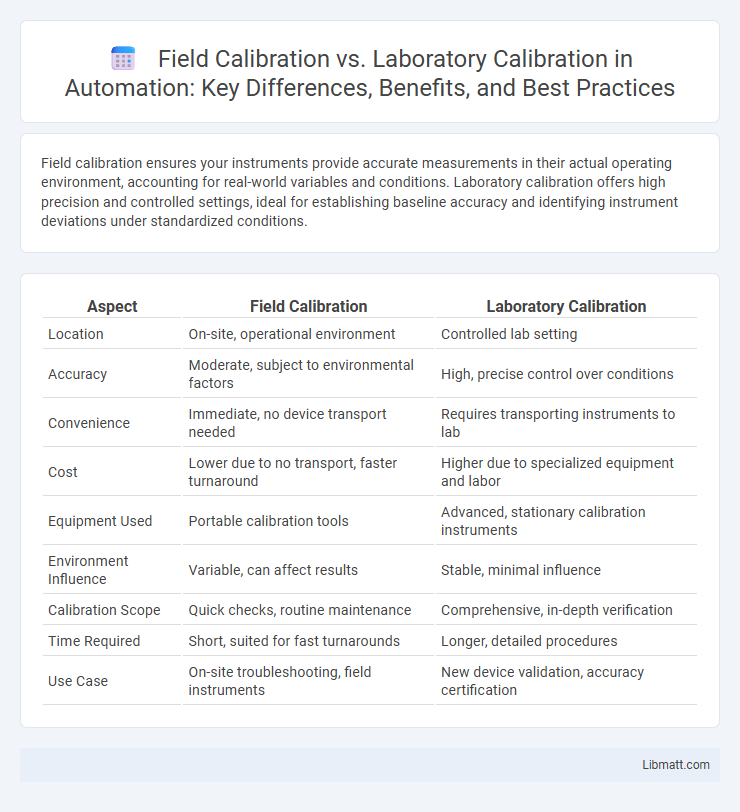

Field calibration ensures your instruments provide accurate measurements in their actual operating environment, accounting for real-world variables and conditions. Laboratory calibration offers high precision and controlled settings, ideal for establishing baseline accuracy and identifying instrument deviations under standardized conditions.

Table of Comparison

| Aspect | Field Calibration | Laboratory Calibration |

|---|---|---|

| Location | On-site, operational environment | Controlled lab setting |

| Accuracy | Moderate, subject to environmental factors | High, precise control over conditions |

| Convenience | Immediate, no device transport needed | Requires transporting instruments to lab |

| Cost | Lower due to no transport, faster turnaround | Higher due to specialized equipment and labor |

| Equipment Used | Portable calibration tools | Advanced, stationary calibration instruments |

| Environment Influence | Variable, can affect results | Stable, minimal influence |

| Calibration Scope | Quick checks, routine maintenance | Comprehensive, in-depth verification |

| Time Required | Short, suited for fast turnarounds | Longer, detailed procedures |

| Use Case | On-site troubleshooting, field instruments | New device validation, accuracy certification |

Introduction to Calibration: Field vs Laboratory

Field calibration is performed on-site using portable instruments to ensure equipment accuracy under actual operating conditions, which helps in maintaining real-time performance and minimizing downtime. Laboratory calibration takes place in controlled environments with highly precise instruments, providing more accurate and traceable measurements for baseline adjustments and compliance with industry standards. Both methods are essential for comprehensive calibration strategies, with field calibration offering convenience and immediate validation, while laboratory calibration delivers thorough accuracy and certification.

Defining Field Calibration

Field calibration involves adjusting and verifying the accuracy of instruments or equipment directly at their operational site, ensuring measurements remain precise under actual working conditions. Unlike laboratory calibration, which occurs in controlled environments with specialized equipment, field calibration accounts for environmental factors such as temperature, humidity, and vibrations that affect performance. Your ability to maintain instrument reliability on-site depends heavily on properly executed field calibration, reducing downtime and ensuring compliance with industry standards.

Understanding Laboratory Calibration

Laboratory calibration involves adjusting and verifying instruments within a controlled environment to ensure high accuracy and repeatability. This process uses advanced equipment and traceable standards to achieve precise measurement alignment, minimizing errors caused by external factors. Unlike field calibration, laboratory calibration provides a stable setting that enhances reliability and consistency in instrument performance validation.

Key Differences between Field and Laboratory Calibration

Field calibration involves adjusting instruments on-site to reflect actual operating conditions, whereas laboratory calibration is performed in controlled environments to ensure precise measurements against standard references. Field calibration addresses real-world variables like temperature, humidity, and pressure, offering practical accuracy tailored to your specific application. Laboratory calibration provides highly accurate, traceable results essential for regulatory compliance and instrument certification.

Accuracy and Precision Comparison

Field calibration often offers rapid adjustments but may sacrifice some accuracy and precision compared to laboratory calibration, which utilizes controlled environments and advanced instruments to ensure higher reliability. Laboratory calibration typically provides traceable standards and minimizes environmental variables, resulting in more consistent and precise measurements. Your choice depends on whether convenience or maximum accuracy and precision are the priority for your specific application.

Environmental Influences on Calibration Results

Field calibration often faces variable environmental influences such as temperature fluctuations, humidity, and dust, which can affect the accuracy and repeatability of calibration results. Laboratory calibration is conducted in controlled environments, minimizing external factors and ensuring precise, consistent measurement standards. This distinction makes laboratory calibration ideal for establishing baseline performance, while field calibration ensures equipment remains accurate under actual operating conditions.

Equipment and Resource Requirements

Field calibration requires portable equipment and minimal resources to perform on-site adjustments, ensuring your devices remain accurate without disrupting operations. Laboratory calibration demands specialized instruments, controlled environments, and skilled technicians to achieve higher precision and traceability standards. Choosing between them depends on the balance between convenience, accuracy, and available resources.

Cost and Time Considerations

Field calibration typically involves lower costs and faster turnaround times since equipment is calibrated on-site, reducing downtime and transportation expenses. Laboratory calibration often incurs higher costs due to specialized facilities and extended processing times, but it provides more precise and comprehensive testing. Your choice depends on balancing budget constraints with the desired accuracy and speed of calibration results.

Applications and Use Cases

Field calibration is ideal for on-site equipment verification, ensuring accurate measurements in environments such as oil rigs, manufacturing plants, and environmental monitoring stations. Laboratory calibration offers controlled conditions and higher precision, often used in research facilities, calibration labs, and industries requiring stringent quality standards. Your choice depends on whether portability and immediate results or maximum accuracy and traceability are crucial for your application.

Choosing the Right Calibration Method

Choosing the right calibration method depends on factors such as accuracy requirements, environmental conditions, and equipment sensitivity. Field calibration offers immediate, on-site adjustments that account for operational conditions, while laboratory calibration provides higher precision through controlled environments and advanced instrumentation. Evaluating the trade-offs between convenience and accuracy ensures optimal performance and reliability of measurement instruments.

Field Calibration vs Laboratory Calibration Infographic

libmatt.com

libmatt.com