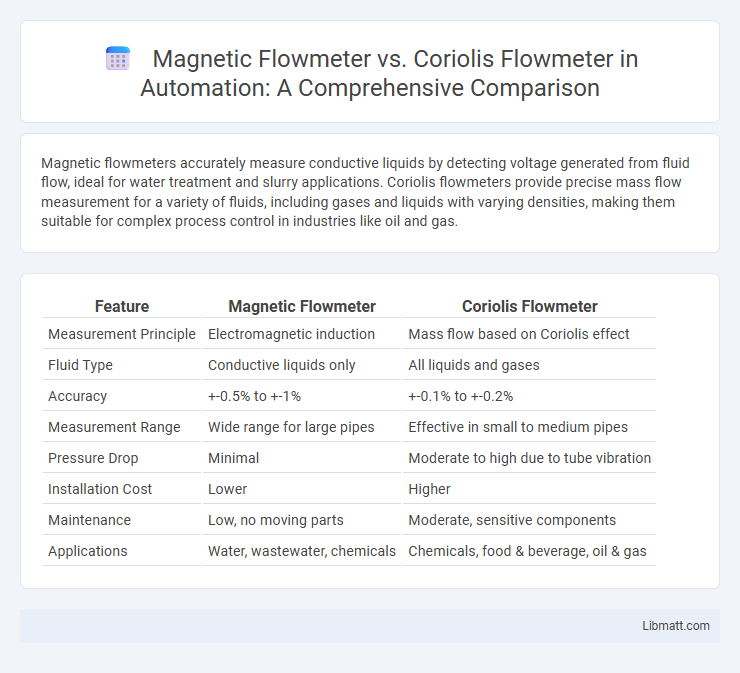

Magnetic flowmeters accurately measure conductive liquids by detecting voltage generated from fluid flow, ideal for water treatment and slurry applications. Coriolis flowmeters provide precise mass flow measurement for a variety of fluids, including gases and liquids with varying densities, making them suitable for complex process control in industries like oil and gas.

Table of Comparison

| Feature | Magnetic Flowmeter | Coriolis Flowmeter |

|---|---|---|

| Measurement Principle | Electromagnetic induction | Mass flow based on Coriolis effect |

| Fluid Type | Conductive liquids only | All liquids and gases |

| Accuracy | +-0.5% to +-1% | +-0.1% to +-0.2% |

| Measurement Range | Wide range for large pipes | Effective in small to medium pipes |

| Pressure Drop | Minimal | Moderate to high due to tube vibration |

| Installation Cost | Lower | Higher |

| Maintenance | Low, no moving parts | Moderate, sensitive components |

| Applications | Water, wastewater, chemicals | Chemicals, food & beverage, oil & gas |

Introduction: Magnetic vs Coriolis Flowmeters

Magnetic flowmeters measure flow velocity by detecting the voltage generated as a conductive fluid passes through a magnetic field, ideal for water, wastewater, and slurry applications. Coriolis flowmeters directly measure mass flow by detecting the deflection caused by fluid inertia in vibrating tubes, providing high accuracy for liquids and gases, including viscous or multiphase fluids. Your choice depends on fluid type, required precision, and application environment, with magnetic flowmeters excelling in conductive fluids and Coriolis offering broader versatility and better accuracy.

Working Principles: Magnetic and Coriolis Explained

Magnetic flowmeters measure fluid velocity by applying a magnetic field and detecting the voltage induced as the conductive liquid passes through the sensor, making them ideal for conductive fluids. Coriolis flowmeters operate on the principle of the Coriolis effect, measuring mass flow rate directly by detecting changes in vibration patterns of oscillating tubes caused by the moving fluid. Your choice depends on the fluid type and measurement accuracy needed, with magnetic flowmeters suited for conductive liquids and Coriolis flowmeters offering precise mass flow measurement for various fluids.

Fluid Compatibility: What Each Meter Measures

Magnetic flowmeters excel at measuring conductive fluids such as water, acids, and slurries, relying on Faraday's law of electromagnetic induction to assess flow velocity without being affected by fluid density, viscosity, or temperature. Coriolis flowmeters measure mass flow directly and are compatible with a wide range of fluids, including liquids, gases, and slurries, regardless of conductivity, enabling precise measurement of fluids with varying densities and compositions. Magnetic flowmeters require conductive fluids, while Coriolis meters offer versatility across conductive and non-conductive fluids with accurate mass flow measurement.

Accuracy and Reliability Comparison

Magnetic flowmeters offer excellent accuracy for conductive liquids, typically within +-0.5%, and are highly reliable due to their lack of moving parts, reducing maintenance needs. Coriolis flowmeters provide superior accuracy, often within +-0.1%, while directly measuring mass flow, making them ideal for mixed-phase or non-conductive fluids. Your choice depends on the required precision and fluid type, with Coriolis meters favored in applications demanding the highest accuracy and reliability.

Installation Requirements and Considerations

Magnetic flowmeters require non-magnetic, conductive fluids and must be installed in full pipe conditions with straight pipe runs upstream and downstream to avoid flow profile disturbances. Coriolis flowmeters demand minimal straight pipe lengths due to their direct mass flow measurement but need careful support to avoid vibrations affecting sensor accuracy. Both flowmeters require grounded pipelines and proper grounding to prevent electrical noise interference, with Coriolis meters typically demanding more space due to their larger sensor bodies.

Maintenance Needs and Operational Lifespan

Magnetic flowmeters require minimal maintenance due to their non-mechanical design, which reduces wear and tear, resulting in a longer operational lifespan especially in corrosive or slurry applications. Coriolis flowmeters involve more complex moving parts and sensors, leading to higher maintenance needs to ensure accuracy and optimal performance over time. Your choice should consider the trade-off between the low maintenance and durability of magnetic flowmeters versus the precision and potential higher upkeep of Coriolis flowmeters.

Cost Comparison: Initial and Long-Term Investment

Magnetic flowmeters generally have a lower initial cost compared to Coriolis flowmeters, making them more budget-friendly for large pipe diameters and simple liquid applications. However, Coriolis flowmeters, despite their higher upfront price, offer more precise measurements and lower maintenance costs over time, which can result in better long-term investment value for complex or multiphase flows. Your choice should weigh the initial budget against potential savings in accuracy and upkeep to determine the most cost-effective solution for your process needs.

Typical Applications in Various Industries

Magnetic flowmeters are widely used in water treatment, wastewater management, and chemical processing industries due to their accuracy in measuring conductive liquids without obstruction. Coriolis flowmeters find typical applications in the oil and gas, food and beverage, and pharmaceutical industries, where precise mass flow measurement and density monitoring are critical. Your choice depends on the specific requirements of liquid type, flow conditions, and measurement precision needed for your industrial process.

Pros and Cons of Magnetic Flowmeters

Magnetic flowmeters offer benefits including high accuracy, no moving parts, and suitability for measuring conductive liquids, making them ideal for water treatment and wastewater applications. However, they cannot measure non-conductive fluids like hydrocarbons and require a fully filled pipe for accurate readings, which limits their versatility. Your choice depends on balancing these strengths against Coriolis flowmeters' ability to measure mass flow and handle a wider fluid range with higher precision.

Pros and Cons of Coriolis Flowmeters

Coriolis flowmeters provide highly accurate mass flow measurements and can handle a wide range of fluids, including viscous and multi-phase mixtures, making them ideal for complex industrial processes. Their main drawbacks include higher upfront costs and sensitivity to external vibrations, which may require additional maintenance or installation considerations. Despite these challenges, Coriolis flowmeters excel in applications demanding precise flow, density, and temperature data simultaneously.

Magnetic Flowmeter vs Coriolis Flowmeter Infographic

libmatt.com

libmatt.com