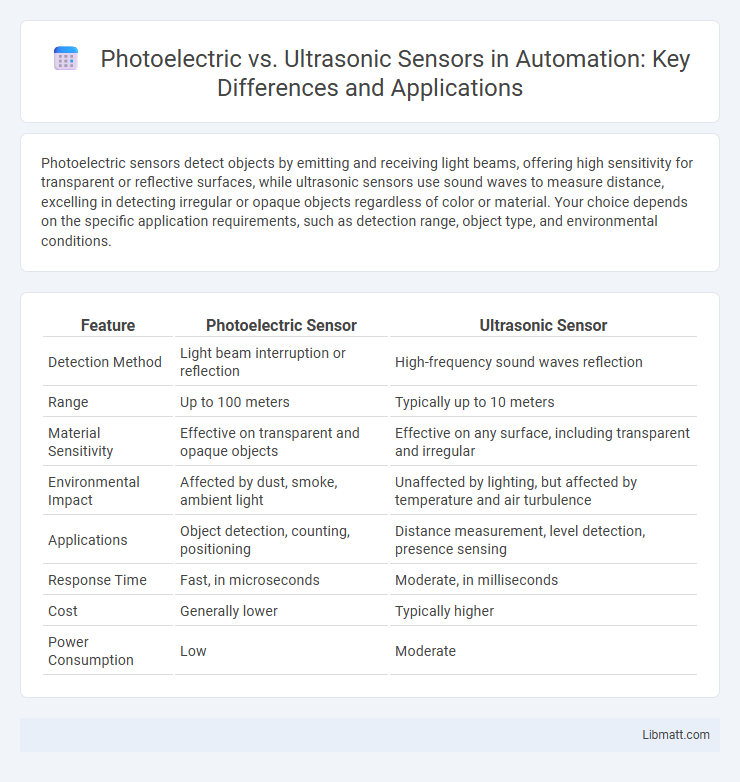

Photoelectric sensors detect objects by emitting and receiving light beams, offering high sensitivity for transparent or reflective surfaces, while ultrasonic sensors use sound waves to measure distance, excelling in detecting irregular or opaque objects regardless of color or material. Your choice depends on the specific application requirements, such as detection range, object type, and environmental conditions.

Table of Comparison

| Feature | Photoelectric Sensor | Ultrasonic Sensor |

|---|---|---|

| Detection Method | Light beam interruption or reflection | High-frequency sound waves reflection |

| Range | Up to 100 meters | Typically up to 10 meters |

| Material Sensitivity | Effective on transparent and opaque objects | Effective on any surface, including transparent and irregular |

| Environmental Impact | Affected by dust, smoke, ambient light | Unaffected by lighting, but affected by temperature and air turbulence |

| Applications | Object detection, counting, positioning | Distance measurement, level detection, presence sensing |

| Response Time | Fast, in microseconds | Moderate, in milliseconds |

| Cost | Generally lower | Typically higher |

| Power Consumption | Low | Moderate |

Introduction to Photoelectric and Ultrasonic Sensors

Photoelectric sensors use light beams to detect objects by measuring the interruption or reflection of the beam, making them ideal for detecting transparent or opaque materials with high precision. Ultrasonic sensors emit high-frequency sound waves and calculate the time it takes for the echo to return, enabling accurate distance measurement and object detection in various environmental conditions. Both sensor types are widely applied in automation, robotics, and industrial settings for object detection and proximity sensing.

Working Principles: How Photoelectric and Ultrasonic Sensors Operate

Photoelectric sensors operate by emitting a light beam, typically infrared or visible, which detects objects when the reflected light returns to the sensor's receiver. Ultrasonic sensors function by sending out high-frequency sound waves and measuring the time it takes for the echo to return after hitting an object, calculating distance based on this time delay. Your choice between these sensors depends on application requirements such as object material, distance range, and environmental conditions.

Key Differences Between Photoelectric and Ultrasonic Sensors

Photoelectric sensors use a light beam to detect objects, making them ideal for precise and high-speed applications, while ultrasonic sensors emit sound waves to measure distance and can detect transparent or irregularly shaped objects. Photoelectric sensors are more sensitive to environmental conditions such as dust and light interference, whereas ultrasonic sensors perform well in harsh environments with dust, smoke, or moisture. Your choice depends on the specific application, with photoelectric sensors favored for small object detection and ultrasonic sensors preferred for longer-range or irregular surface detection.

Accuracy and Detection Range Comparison

Photoelectric sensors typically offer high accuracy with detection ranges varying from a few millimeters up to 100 meters depending on the model and environmental conditions, making them ideal for precise object detection in controlled settings. Ultrasonic sensors provide consistent accuracy over medium to long distances, generally ranging from 2 centimeters to 10 meters, excelling in detecting transparent or irregularly shaped objects where photoelectric sensors may struggle. The choice between these sensors depends on the specific application requirements, with ultrasonic sensors often preferred for flexible range and material independence, while photoelectric sensors deliver superior precision in short to moderate distances.

Environmental Factors: Performance in Various Conditions

Photoelectric sensors excel in clean, well-lit environments but can struggle with dust, fog, or reflective surfaces that cause signal interference. Ultrasonic sensors perform reliably in dusty, smoky, or dark conditions as they use sound waves unaffected by lighting or transparency, making them ideal for harsh industrial settings. Your choice depends on the specific environmental challenges your application faces, ensuring consistent sensor performance.

Applications of Photoelectric Sensors

Photoelectric sensors are widely used in industrial automation for object detection, counting, and positioning due to their high accuracy and long sensing range. These sensors excel in applications like packaging, conveyor systems, and robotics where precise detection of transparent or opaque objects is required. Your manufacturing process can benefit significantly from photoelectric sensors by improving efficiency and reducing errors in automated inspection and sorting tasks.

Applications of Ultrasonic Sensors

Ultrasonic sensors are widely used in industrial automation for object detection, distance measurement, and level sensing in liquids and solids due to their ability to function accurately in harsh environments and with transparent or irregular surfaces. They are essential in automotive parking assistance systems, robotic navigation, and conveyor control systems, providing reliable detection without contact. Your choice of sensor can leverage ultrasonic technology to improve precision and durability in applications requiring non-contact measurement.

Pros and Cons: Photoelectric vs Ultrasonic Sensors

Photoelectric sensors offer high accuracy and fast response times, making them ideal for detecting small objects and transparent materials, but they are sensitive to dust, dirt, and ambient light interference. Ultrasonic sensors excel in detecting objects regardless of color or transparency and perform well in harsh environments, though they have limited range and may struggle with soft or angled surfaces. Choosing between photoelectric and ultrasonic sensors depends on the application's environmental conditions, object characteristics, and required detection distance.

Selection Criteria: Which Sensor Should You Choose?

Photoelectric sensors excel in detecting objects with varying surface colors and transparencies, making them ideal for applications needing precise detection over longer distances, typically up to several meters. Ultrasonic sensors are preferable for measuring distance to objects regardless of color or material, especially effective in dusty, humid, or transparent environments, with sensing ranges usually between 30 cm and 10 meters. Choosing the right sensor depends on factors like detection range, target material, environmental conditions, and required accuracy to ensure optimal performance and reliability in industrial automation.

Future Trends in Sensor Technology

Future trends in sensor technology reveal significant advancements in Photoelectric and Ultrasonic sensors, driven by developments in AI integration, IoT connectivity, and enhanced precision through machine learning algorithms. Photoelectric sensors are evolving with improved wavelength selectivity and longer detection ranges, while Ultrasonic sensors are benefiting from increased frequency modulation and miniaturization for better resolution in compact devices. The convergence of these sensors with smart systems enables predictive maintenance, real-time data processing, and greater adaptability across industries like automotive, manufacturing, and robotics.

Photoelectric vs Ultrasonic Sensor Infographic

libmatt.com

libmatt.com