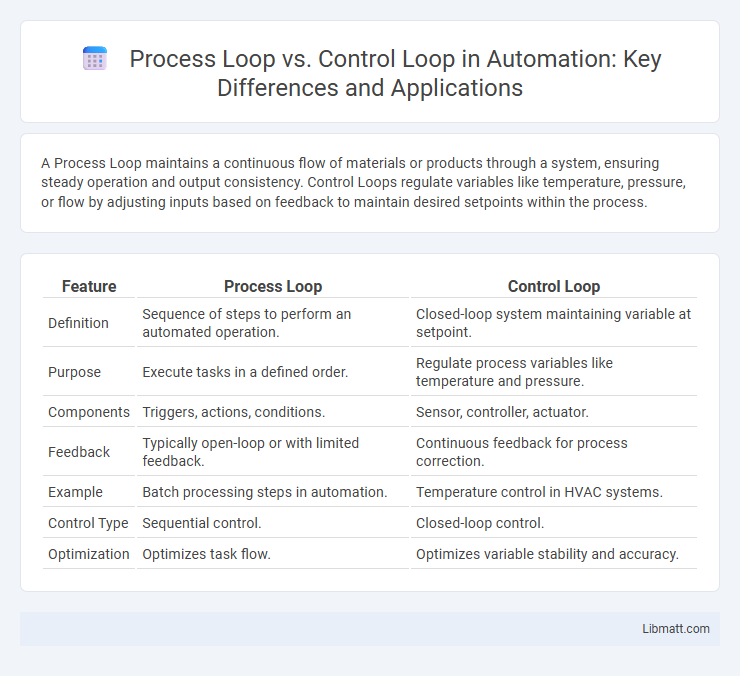

A Process Loop maintains a continuous flow of materials or products through a system, ensuring steady operation and output consistency. Control Loops regulate variables like temperature, pressure, or flow by adjusting inputs based on feedback to maintain desired setpoints within the process.

Table of Comparison

| Feature | Process Loop | Control Loop |

|---|---|---|

| Definition | Sequence of steps to perform an automated operation. | Closed-loop system maintaining variable at setpoint. |

| Purpose | Execute tasks in a defined order. | Regulate process variables like temperature and pressure. |

| Components | Triggers, actions, conditions. | Sensor, controller, actuator. |

| Feedback | Typically open-loop or with limited feedback. | Continuous feedback for process correction. |

| Example | Batch processing steps in automation. | Temperature control in HVAC systems. |

| Control Type | Sequential control. | Closed-loop control. |

| Optimization | Optimizes task flow. | Optimizes variable stability and accuracy. |

Introduction to Process Loops and Control Loops

Process loops and control loops are fundamental concepts in automation and industrial control systems, with process loops managing the overall system behavior and control loops focusing on maintaining specific variables within set parameters. Process loops integrate multiple control loops to regulate complex processes such as temperature, pressure, or flow in manufacturing plants. Control loops use feedback from sensors to continuously adjust actuators, ensuring precise control over individual process variables for stability and efficiency.

Defining Process Loop: Key Concepts

A Process Loop refers to a continuous sequence of operations where the output of one stage becomes the input for the next, maintaining system stability and performance. Key concepts include feedback control, where sensors monitor process variables such as temperature or pressure, and actuators adjust inputs to achieve desired setpoints. This loop ensures real-time regulation and optimization of industrial processes, distinguishing it from a Control Loop, which primarily focuses on controlling a specific variable through a single feedback mechanism.

Defining Control Loop: Essential Elements

A Control Loop consists of essential elements including a sensor to measure the process variable, a controller that compares the measured value to a setpoint, and an actuator that adjusts the process accordingly. This continuous feedback mechanism maintains system stability and desired output despite external disturbances. Understanding these components helps you optimize process automation and achieve precise control in industrial environments.

Core Differences Between Process and Control Loops

Process loops manage the overall workflow and sequence of operations within industrial systems, focusing on ensuring that complex tasks are executed in the correct order. Control loops regulate specific variables like temperature, pressure, or flow by continuously measuring and adjusting the process parameters to maintain desired setpoints. The core difference lies in their scope: process loops orchestrate multiple control loops and actions to achieve broader operational objectives, while control loops handle real-time, automatic adjustments of individual process variables.

Components of a Process Loop

A process loop consists of sensors, controllers, and final control elements that work together to monitor and adjust process variables such as temperature, pressure, or flow. Sensors detect real-time data and send signals to the controller, which compares the measurements to setpoints and determines necessary adjustments. Final control elements like valves or actuators execute the controller's commands to maintain the desired process conditions within specified limits.

Components of a Control Loop

A control loop consists of key components such as the sensor, controller, and final control element, which work together to maintain process variables within desired setpoints. The sensor measures the process variable and sends feedback to the controller, which compares it with the setpoint and sends corrective signals to the final control element, typically a valve or actuator. This continuous feedback mechanism distinguishes control loops from general process loops by enabling automated, precise regulation of industrial processes.

Functionality Comparison: Process Loop vs Control Loop

Process loops manage the sequential flow of operations in industrial systems by triggering steps based on predefined conditions to ensure tasks execute in the correct order. Control loops regulate specific process variables like temperature, pressure, or flow by continuously measuring and adjusting inputs through feedback mechanisms to maintain desired setpoints. Understanding the functionality differences between process loops and control loops helps optimize your automation strategy for improved system efficiency and stability.

Real-World Applications of Process and Control Loops

Process loops are fundamental in industries such as chemical manufacturing, where they regulate variables like temperature, pressure, and flow to maintain consistent product quality and safety. Control loops are essential in automation systems for maintaining desired setpoints in HVAC systems, robotics, and automotive cruise control by continuously adjusting actuators based on sensor feedback. Both types of loops optimize operational efficiency and minimize human intervention in complex systems.

Benefits and Limitations of Each Loop Type

Process loops offer precise regulation of continuous variables such as temperature or flow, enhancing system stability and product quality, but they may require complex tuning and are sensitive to sensor inaccuracies. Control loops excel in maintaining setpoints through feedback mechanisms, providing robustness in dynamic environments, though they can be slower to respond to rapid changes and may involve higher implementation costs. Selecting between process and control loops depends on the specific application needs, balancing accuracy, responsiveness, and system complexity.

Choosing the Right Loop for Industrial Automation

Selecting the appropriate loop type in industrial automation hinges on the specific application requirements: process loops are ideal for controlling continuous variables like temperature, pressure, or flow in chemical and manufacturing processes, while control loops excel in discrete control tasks such as starting and stopping motors or actuators. Process loops utilize feedback mechanisms and PID controllers to maintain setpoints within tight tolerances, ensuring product quality and system stability. Control loops often employ simpler on/off or ladder logic control, prioritizing speed and reliability in automation systems where precise variable modulation is less critical.

Process Loop vs Control Loop Infographic

libmatt.com

libmatt.com