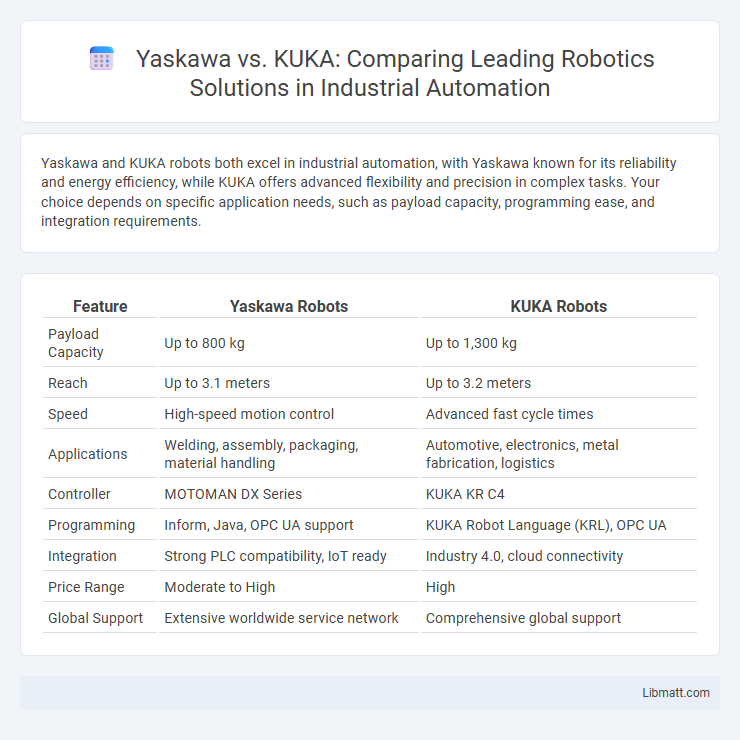

Yaskawa and KUKA robots both excel in industrial automation, with Yaskawa known for its reliability and energy efficiency, while KUKA offers advanced flexibility and precision in complex tasks. Your choice depends on specific application needs, such as payload capacity, programming ease, and integration requirements.

Table of Comparison

| Feature | Yaskawa Robots | KUKA Robots |

|---|---|---|

| Payload Capacity | Up to 800 kg | Up to 1,300 kg |

| Reach | Up to 3.1 meters | Up to 3.2 meters |

| Speed | High-speed motion control | Advanced fast cycle times |

| Applications | Welding, assembly, packaging, material handling | Automotive, electronics, metal fabrication, logistics |

| Controller | MOTOMAN DX Series | KUKA KR C4 |

| Programming | Inform, Java, OPC UA support | KUKA Robot Language (KRL), OPC UA |

| Integration | Strong PLC compatibility, IoT ready | Industry 4.0, cloud connectivity |

| Price Range | Moderate to High | High |

| Global Support | Extensive worldwide service network | Comprehensive global support |

Overview of Yaskawa and KUKA Robotics

Yaskawa and KUKA are leading manufacturers in the industrial robotics sector, offering advanced automation solutions tailored for diverse industries. Yaskawa specializes in high-performance Motoman robots renowned for precision and durability, while KUKA provides innovative robotic systems celebrated for flexibility and integration capabilities. Your choice between these brands depends on specific application requirements such as load capacity, reach, and ease of programming.

Core Technologies and Innovations

Yaskawa excels in servo motor technology and motion control systems, making its robots highly precise for industrial automation. KUKA leads with advanced robotics software and artificial intelligence integration, enhancing adaptability in complex manufacturing environments. Your choice depends on the need for Yaskawa's robust mechanical efficiency or KUKA's cutting-edge digital innovation in robotic solutions.

Key Robot Models Comparison

Yaskawa's Motoman series, such as the GP series for general purpose and the MP series for high-speed applications, emphasizes precision and versatility, making it ideal for manufacturing and automation tasks. KUKA offers models like the KR AGILUS for high-speed and compact tasks, and the KR QUANTEC for heavy payloads and extended reach, focusing on flexibility and robust performance across industries. When choosing between these robots, your application requirements, including payload, reach, speed, and precision, play a critical role in selecting the optimal robotic solution.

Industrial Applications and Use Cases

Yaskawa robots excel in high-speed packaging, assembly, and material handling tasks, making them ideal for electronics, automotive, and food industries. KUKA robots are favored for heavy-duty applications such as welding, palletizing, and intricate automotive manufacturing processes due to their payload capacity and precision. Your choice depends on the specific industrial application, with Yaskawa suited for fast, repetitive tasks and KUKA optimized for complex, high-load operations.

Programming and Software Ecosystems

Yaskawa robots utilize the proprietary Motoman Robotics Suite, offering intuitive programming with support for MotoPlus and Inform languages, enhancing real-time control and integration capabilities. KUKA robots operate on the KUKA Robot Language (KRL) within the KUKA Sunrise.OS environment, providing a robust Java-based platform that facilitates advanced application development and extensive compatibility with industry 4.0 standards. Both ecosystems emphasize user-friendly interfaces and flexible software tools, optimizing robot programming for diverse industrial automation tasks.

Precision, Speed, and Payload Capabilities

Yaskawa robots excel in precision with repeatability often within +-0.02 mm, making them ideal for intricate tasks, while KUKA robots also offer high precision but generally around +-0.03 mm. In terms of speed, Yaskawa models such as the Motoman series achieve rapid cycle times suited for high-throughput manufacturing, whereas KUKA robots prioritize a balance between speed and flexibility, with top speeds slightly lower but optimized for varied applications. Payload capabilities vary significantly, with KUKA providing heavy-duty options exceeding 300 kg, outperforming many Yaskawa robots whose payload capacity typically maxes out around 100 kg, allowing you to select based on load requirements specific to your operation.

Integration and Compatibility

Yaskawa robots excel in seamless integration with various automation platforms due to their open architecture and extensive support for industry protocols like EtherCAT, facilitating smooth communication within existing systems. KUKA robots offer robust compatibility through KUKA's proprietary KUKA.PLC mxAutomation interface, allowing direct real-time control from PLCs, which enhances flexibility in complex manufacturing environments. When selecting your robotic solution, consider Yaskawa's ease of integration for diverse applications or KUKA's advanced compatibility for precise, PLC-driven processes.

Maintenance and Technical Support

Yaskawa robots offer extensive maintenance packages featuring remote diagnostics and preventive maintenance to minimize downtime, supported by a global network of specialized technicians. KUKA provides comprehensive technical support through authorized service centers with rapid response teams and robust training programs designed to enhance user expertise. Both manufacturers emphasize tailored maintenance solutions and proactive technical assistance to ensure operational efficiency and extend robot lifespan.

Pricing and Total Cost of Ownership

Yaskawa robots generally offer competitive pricing with lower initial costs compared to KUKA, making them an attractive option for budget-conscious buyers. The total cost of ownership for Yaskawa tends to be reduced due to their energy-efficient designs and lower maintenance expenses. Evaluating your specific application needs can help determine which brand delivers the best return on investment over time.

Market Presence and Customer Reviews

Yaskawa commands a strong market presence with its MOTOMAN series widely trusted for reliability in diverse industries such as automotive and electronics, while KUKA excels in advanced automation solutions, particularly in heavy-duty applications and collaborative robots. Customer reviews highlight Yaskawa's user-friendly programming and consistent performance, whereas KUKA robots receive praise for precision, innovative technology, and flexibility in complex tasks. Both brands lead globally but differ in specialization, with Yaskawa favored for versatility and KUKA preferred for high-end industrial robotics.

Yaskawa vs KUKA Robots Infographic

libmatt.com

libmatt.com