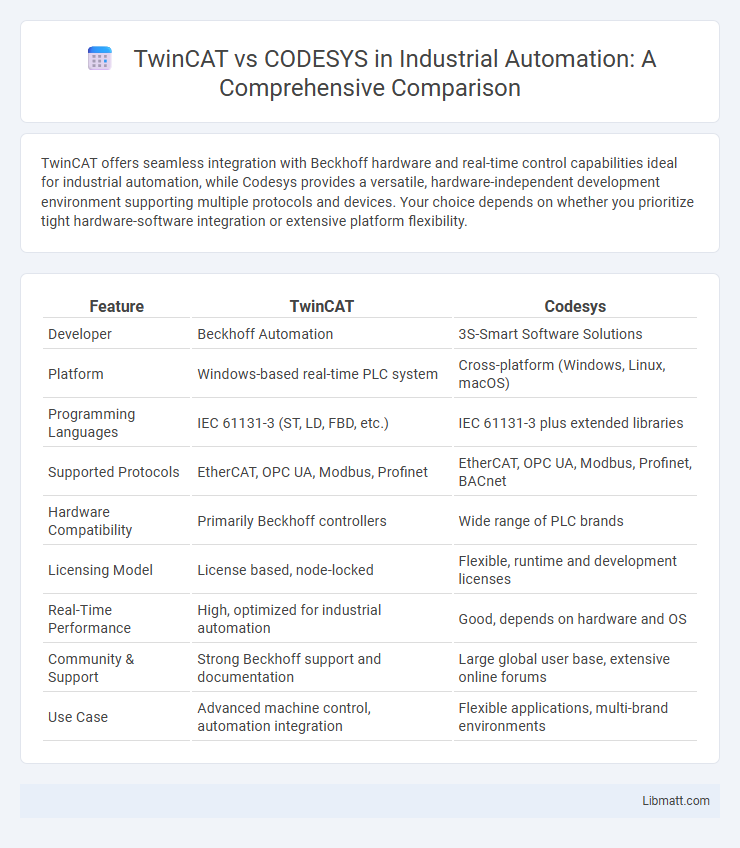

TwinCAT offers seamless integration with Beckhoff hardware and real-time control capabilities ideal for industrial automation, while Codesys provides a versatile, hardware-independent development environment supporting multiple protocols and devices. Your choice depends on whether you prioritize tight hardware-software integration or extensive platform flexibility.

Table of Comparison

| Feature | TwinCAT | Codesys |

|---|---|---|

| Developer | Beckhoff Automation | 3S-Smart Software Solutions |

| Platform | Windows-based real-time PLC system | Cross-platform (Windows, Linux, macOS) |

| Programming Languages | IEC 61131-3 (ST, LD, FBD, etc.) | IEC 61131-3 plus extended libraries |

| Supported Protocols | EtherCAT, OPC UA, Modbus, Profinet | EtherCAT, OPC UA, Modbus, Profinet, BACnet |

| Hardware Compatibility | Primarily Beckhoff controllers | Wide range of PLC brands |

| Licensing Model | License based, node-locked | Flexible, runtime and development licenses |

| Real-Time Performance | High, optimized for industrial automation | Good, depends on hardware and OS |

| Community & Support | Strong Beckhoff support and documentation | Large global user base, extensive online forums |

| Use Case | Advanced machine control, automation integration | Flexible applications, multi-brand environments |

Introduction to TwinCAT and Codesys

TwinCAT and CODESYS are leading industrial automation software platforms widely used for PLC programming and control system integration. TwinCAT, developed by Beckhoff Automation, transforms PCs into real-time controllers with extensive support for automation hardware and robust IEC 61131-3 compliance. CODESYS, created by the CODESYS Group, offers a versatile, independent development environment supporting multiple hardware manufacturers and comprehensive libraries for diverse industrial applications.

Core Features Comparison

TwinCAT offers real-time automation with integrated PLC, NC, and CNC functions, supporting complex motion control and extensive hardware compatibility. Codesys provides a flexible IEC 61131-3 environment with a broad range of device support and modular libraries for easy customization. Your choice depends on whether you prioritize TwinCAT's tight integration with Beckhoff hardware or Codesys's versatility across diverse platforms.

Supported Hardware Platforms

TwinCAT primarily supports Beckhoff Automation hardware, allowing seamless integration with their PLCs, IPCs, and embedded control devices. Codesys offers extensive compatibility across a broad range of hardware platforms from various manufacturers, including industrial PCs, embedded systems, and microcontrollers. Your choice depends on whether you prioritize Beckhoff-specific optimization or flexible cross-platform support.

Programming Language Support

TwinCAT supports multiple programming languages defined by IEC 61131-3, including Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Instruction List (IL), and Sequential Function Chart (SFC), offering flexibility for diverse automation projects. CODESYS also provides comprehensive support for these standard IEC 61131-3 languages and extends compatibility with object-oriented programming using CFC (Continuous Function Chart) and integration with higher-level languages like C and C++. Your choice between TwinCAT and CODESYS may depend on the specific programming language requirements and the ease of integrating object-oriented concepts within your control system.

Development Environment and User Interface

TwinCAT offers an integrated development environment (IDE) with a user-friendly interface tailored for seamless automation programming, featuring advanced debugging tools and real-time task visualization. Codesys provides a flexible and customizable development platform supporting multiple IEC 61131-3 languages, with an intuitive graphical user interface that simplifies project navigation and device configuration. Both environments prioritize efficiency but differ in user interface layout, with TwinCAT favoring a structured, Microsoft Visual Studio-like setup and Codesys emphasizing modularity and extensibility for various industrial applications.

Integration and Compatibility

TwinCAT offers seamless integration with Beckhoff hardware and supports real-time control through a unified development environment, enhancing compatibility with industrial Ethernet protocols like EtherCAT. Codesys provides broad hardware compatibility across multiple vendors and supports various fieldbus systems such as Modbus, CANopen, and PROFINET, enabling flexible integration into diverse automation setups. Both platforms facilitate integration with PLC, HMI, and motion control systems, but TwinCAT excels in Beckhoff-centric environments while Codesys is favored for cross-vendor interoperability.

Performance and Scalability

TwinCAT offers high-performance real-time control with tight integration into Beckhoff hardware, ensuring minimal latency and efficient multitasking suitable for complex automation tasks. CODESYS excels in scalability, supporting a wide range of hardware platforms and allowing seamless deployment from small-scale controllers to large, distributed systems, making it flexible for diverse industrial environments. Your choice depends on whether you prioritize optimized performance on specific hardware (TwinCAT) or broad scalability across multiple device types (CODESYS).

Safety and Security Features

TwinCAT offers integrated safety features compliant with SIL 3 standards through its TwinSAFE system, enabling seamless safety and automation integration on Beckhoff hardware. Codesys provides safety solutions certified up to SIL 3 and PL e, with flexible support for diverse hardware platforms and an open safety runtime environment, enhancing adaptability. Both platforms emphasize secure communication protocols and IEC 62443 compliance to ensure robust cybersecurity in industrial automation environments.

Licensing and Cost Structure

TwinCAT offers a modular licensing model with a base runtime license plus additional costs for advanced functionalities, making it suitable for scalable industrial automation projects with varying budget sizes. Codesys provides a more flexible cost structure, often including a free runtime license for certain controllers and pay-per-feature licenses that can reduce initial expenses, appealing to smaller operations or those with tighter budgets. Your choice between the two should consider not only upfront costs but also long-term licensing fees tied to software updates and support.

Industry Applications and Case Studies

TwinCAT excels in high-precision motion control and complex automation tasks, widely adopted in automotive manufacturing and packaging industries for real-time performance and deterministic control. Codesys offers versatile multi-platform support and extensive device compatibility, making it ideal for building automation and energy management projects with numerous documented case studies in smart grid integration. Your choice between TwinCAT and Codesys depends on the specific industry requirements, control complexity, and existing ecosystem integration.

TwinCAT vs Codesys Infographic

libmatt.com

libmatt.com