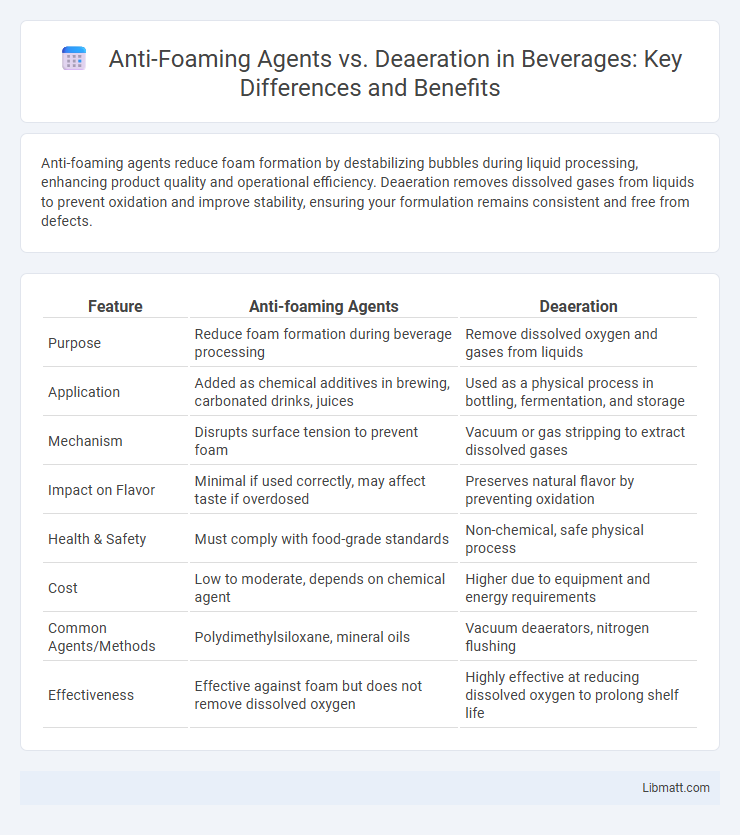

Anti-foaming agents reduce foam formation by destabilizing bubbles during liquid processing, enhancing product quality and operational efficiency. Deaeration removes dissolved gases from liquids to prevent oxidation and improve stability, ensuring your formulation remains consistent and free from defects.

Table of Comparison

| Feature | Anti-foaming Agents | Deaeration |

|---|---|---|

| Purpose | Reduce foam formation during beverage processing | Remove dissolved oxygen and gases from liquids |

| Application | Added as chemical additives in brewing, carbonated drinks, juices | Used as a physical process in bottling, fermentation, and storage |

| Mechanism | Disrupts surface tension to prevent foam | Vacuum or gas stripping to extract dissolved gases |

| Impact on Flavor | Minimal if used correctly, may affect taste if overdosed | Preserves natural flavor by preventing oxidation |

| Health & Safety | Must comply with food-grade standards | Non-chemical, safe physical process |

| Cost | Low to moderate, depends on chemical agent | Higher due to equipment and energy requirements |

| Common Agents/Methods | Polydimethylsiloxane, mineral oils | Vacuum deaerators, nitrogen flushing |

| Effectiveness | Effective against foam but does not remove dissolved oxygen | Highly effective at reducing dissolved oxygen to prolong shelf life |

Introduction to Anti-Foaming Agents and Deaeration

Anti-foaming agents and deaeration are essential processes in industries to manage unwanted air and foam in liquids, improving product quality and process efficiency. Anti-foaming agents chemically reduce foam formation by destabilizing bubbles, while deaeration physically removes dissolved gases from liquids to prevent oxidation and other complications. Your selection between these methods depends on the specific application requirements, such as foam control or gas removal, ensuring optimal performance in manufacturing or processing environments.

Understanding Foam Formation in Industrial Processes

Foam formation in industrial processes occurs due to the entrapment of gas bubbles in liquids, often caused by surfactants, agitation, or rapid gas flow. Anti-foaming agents interrupt foam stability by reducing surface tension, allowing bubbles to coalesce and collapse more quickly. Deaeration, on the other hand, removes dissolved gases from liquids before processing, preventing foam creation at the source rather than controlling it after formation.

What Are Anti-Foaming Agents?

Anti-foaming agents are chemical compounds designed to reduce or prevent foam formation in liquids during industrial processes, enhancing efficiency and product quality. They work by disrupting bubble stability, causing foam to collapse quickly without affecting the liquid's other properties. Your process can benefit from anti-foaming agents by minimizing foam-related disruptions, unlike deaeration, which removes dissolved gases rather than controlling surface foam.

How Deaeration Works in Fluid Management

Deaeration in fluid management removes dissolved gases, primarily oxygen and nitrogen, by heating the fluid and reducing pressure, causing gases to escape before fluid processing. Anti-foaming agents work differently by reducing surface tension to prevent foam formation during agitation or mixing but do not remove dissolved gases. Your process efficiency improves significantly with proper deaeration, as it minimizes corrosion and contamination caused by trapped gases.

Key Differences: Anti-Foaming Agents vs Deaeration

Anti-foaming agents are chemical additives designed to reduce or prevent foam formation in liquids during industrial processes, whereas deaeration is a mechanical or thermal process aimed at removing dissolved gases, primarily oxygen, from liquids like water or fuel. Anti-foaming agents act quickly by destabilizing foam bubbles, improving product quality and process efficiency, while deaeration enhances the lifespan of equipment by minimizing corrosion caused by dissolved gases. The primary distinction lies in their function: anti-foaming agents control surface foam, and deaeration removes entrapped gases to protect systems and optimize performance.

Applications of Anti-Foaming Agents Across Industries

Anti-foaming agents are essential in industries such as pharmaceuticals, food processing, and wastewater treatment to prevent foam formation that disrupts manufacturing efficiency. These agents improve product quality by minimizing foam-related defects during mixing, fermentation, and chemical reactions, ensuring smooth processing and consistent output. Unlike deaeration, which removes dissolved gases, anti-foaming agents specifically target the stabilization and breakdown of foam on liquid surfaces.

Common Uses of Deaeration Techniques

Deaeration techniques are commonly used in industries such as water treatment, pharmaceuticals, and food processing to remove dissolved gases like oxygen and carbon dioxide, preventing corrosion and spoilage. These methods improve product stability by reducing oxidation and enhance equipment longevity by minimizing gas-related damage in boilers and pipelines. Deaeration plays a crucial role in beverage production, ensuring quality and extending shelf life by eliminating unwanted gases prior to packaging.

Pros and Cons: Anti-Foaming Agents Compared to Deaeration

Anti-foaming agents rapidly reduce surface foam and prevent its formation in liquids, providing immediate control during manufacturing processes, but they may introduce chemical residues and require continuous addition. Deaeration removes dissolved gases from liquids, improving product stability and shelf life without chemical additives, yet it demands more complex equipment and higher operational costs. While anti-foaming agents offer quick and flexible foam management, deaeration delivers long-term quality benefits by fundamentally reducing gas content.

Selecting the Right Solution: Factors to Consider

Selecting the right solution between anti-foaming agents and deaeration depends on your process requirements, including the type of liquid, foam characteristics, and sensitivity to air content. Anti-foaming agents chemically reduce surface tension to prevent foam formation, ideal for continuous processes with persistent foaming issues. Deaeration physically removes dissolved gases, making it the preferred choice when minimizing oxygen content is critical to product quality or stability.

Future Trends in Foam Control Technology

Future trends in foam control technology emphasize the integration of advanced anti-foaming agents with novel deaeration methods to enhance efficiency and reduce chemical usage. Innovations include bio-based formulations and automated systems that monitor and adjust foam levels in real-time, optimizing your production process. These developments aim to address environmental concerns while ensuring precise foam management across industries.

Anti-foaming agents vs deaeration Infographic

libmatt.com

libmatt.com