Alkali Silica Reaction (ASR) causes internal cracking in concrete due to a chemical reaction between alkalis and reactive silica in aggregates, while Sulfate Attack results from sulfate ions reacting with concrete components, leading to surface deterioration and expansion. Understanding these processes helps you select the right preventive measures for durable concrete structures.

Table of Comparison

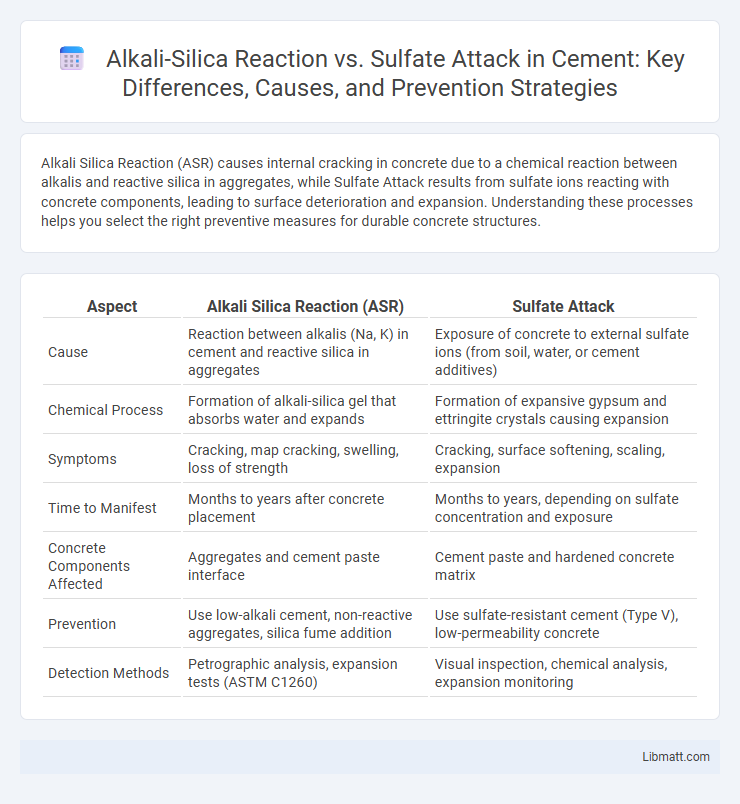

| Aspect | Alkali Silica Reaction (ASR) | Sulfate Attack |

|---|---|---|

| Cause | Reaction between alkalis (Na, K) in cement and reactive silica in aggregates | Exposure of concrete to external sulfate ions (from soil, water, or cement additives) |

| Chemical Process | Formation of alkali-silica gel that absorbs water and expands | Formation of expansive gypsum and ettringite crystals causing expansion |

| Symptoms | Cracking, map cracking, swelling, loss of strength | Cracking, surface softening, scaling, expansion |

| Time to Manifest | Months to years after concrete placement | Months to years, depending on sulfate concentration and exposure |

| Concrete Components Affected | Aggregates and cement paste interface | Cement paste and hardened concrete matrix |

| Prevention | Use low-alkali cement, non-reactive aggregates, silica fume addition | Use sulfate-resistant cement (Type V), low-permeability concrete |

| Detection Methods | Petrographic analysis, expansion tests (ASTM C1260) | Visual inspection, chemical analysis, expansion monitoring |

Introduction to Alkali Silica Reaction and Sulfate Attack

Alkali Silica Reaction (ASR) is a chemical reaction between alkalis in cement and reactive silica in aggregates, causing expansion and cracking in concrete. Sulfate Attack involves the ingress of sulfate ions into concrete, leading to the formation of expansive products like ettringite that degrade structural integrity. Understanding these mechanisms helps you prevent durability issues in concrete structures.

Chemical Mechanisms: ASR vs Sulfate Attack

Alkali Silica Reaction (ASR) involves a chemical reaction between alkaline cement pore solutions and reactive silica in aggregates, producing a gel that expands by absorbing water, leading to internal tensile stresses and cracking. Sulfate Attack occurs when external sulfates penetrate concrete, reacting with calcium aluminate hydrates to form expansive products like ettringite and gypsum, causing crystallization pressure and matrix deterioration. Both mechanisms induce expansion and cracking but differ in reactive species and infiltration sources, with ASR driven by internal alkali-silica gel formation and sulfate attack by external sulfate ion ingress and salt crystallization.

Common Causes and Contributing Factors

Alkali Silica Reaction (ASR) is commonly caused by the reaction between alkalis in cement and reactive silica in aggregates, leading to gel formation and expansion, while sulfate attack results from the ingress of external sulfates reacting with hydrated cement minerals, causing expansion and deterioration. High alkali content in cement, reactive aggregate minerals, and moisture presence significantly contribute to ASR, whereas sulfate attack is exacerbated by exposure to sulfate-rich environments such as soil or groundwater and poor concrete permeability. Both deterioration mechanisms are influenced by factors like temperature, concrete composition, and curing conditions that affect reaction rates and severity.

Affected Concrete Structures and Risk Areas

Alkali Silica Reaction (ASR) predominantly affects concrete structures containing reactive silica aggregates, especially in dams, bridges, and pavements exposed to moisture. Sulfate attack targets concrete exposed to sulfate-rich environments such as soils, groundwater, and seawater, impacting foundations, sewer systems, and marine structures. Risk areas for ASR include regions with high-alkali cement and reactive aggregates, while sulfate attack is common in coastal zones and sulfate-laden soils.

Visual Symptoms and Signs of Deterioration

Alkali Silica Reaction (ASR) typically manifests as cracked or map-like patterns on concrete surfaces, often accompanied by gel exudation and localized swelling, indicating internal expansion caused by reactive silica. Sulfate attack, in contrast, causes surface scaling, spalling, and powdery deposits due to chemical reactions between sulfates and concrete constituents, leading to loss of material strength and increased porosity. Recognizing these distinct visual symptoms helps you identify whether your concrete deterioration stems from alkali silica reaction or sulfate attack.

Microstructural Changes and Damage Patterns

Alkali Silica Reaction (ASR) causes expansion and cracking in concrete due to the formation of a gel that absorbs water and exerts internal pressure, leading to microcracks and disrupted aggregate-paste interfaces. Sulfate Attack results in the formation of expansive ettringite and gypsum crystals, causing swelling, cracking, and delamination primarily in the cement paste and near the aggregate-cement interface. Your concrete's durability can be compromised differently depending on whether ASR or sulfate attack dominates, as each triggers distinct microstructural alterations and damage patterns.

Performance Impacts on Concrete Durability

Alkali Silica Reaction (ASR) causes expansive gel formation within concrete pores, leading to cracking, reduced strength, and diminished durability over time. Sulfate Attack results in chemical reactions that produce ettringite and gypsum, causing severe surface scaling, loss of cohesion, and increased permeability. Understanding these mechanisms helps you manage concrete mix designs and protective measures to enhance long-term structural performance.

Prevention and Mitigation Strategies

Preventing Alkali Silica Reaction (ASR) involves using low-alkali cement, incorporating supplementary cementitious materials like fly ash or slag, and selecting non-reactive aggregates to reduce silica reactivity. Sulfate attack mitigation requires sulfate-resistant cement types such as Type V Portland cement, adequate concrete cover, and low water-to-cement ratios to limit sulfate ingress and expansion. Proper curing, quality control, and use of corrosion inhibitors further improve durability against both ASR and sulfate-induced deterioration.

Testing Methods for Detection and Diagnosis

Testing methods for detecting Alkali Silica Reaction (ASR) include petrographic analysis, accelerated mortar bar tests (ASTM C1260), and concrete prism tests (ASTM C1293) to assess expansion caused by reactive silica and alkali interaction. For Sulfate Attack, techniques such as sulfate resistance tests (ASTM C1012), X-ray diffraction (XRD), and scanning electron microscopy (SEM) are used to identify sulfate ions and monitor physical deterioration due to sulfate ingress. Your choice of diagnostic testing should align with the specific degradation symptoms and exposure conditions of the concrete structure.

Comparative Analysis: ASR vs Sulfate Attack in Practice

Alkali Silica Reaction (ASR) and Sulfate Attack both deteriorate concrete but differ in mechanisms and impact timelines. ASR involves a chemical reaction between alkalis in cement and reactive silica in aggregates, causing expansive gel formation and cracking over months to years. Sulfate Attack stems from external sulfate ions reacting with hydrated cement paste, leading to expansion, cracking, and strength loss typically in aggressive environments with sulfate-rich soils or waters.

Alkali Silica Reaction vs Sulfate Attack Infographic

libmatt.com

libmatt.com