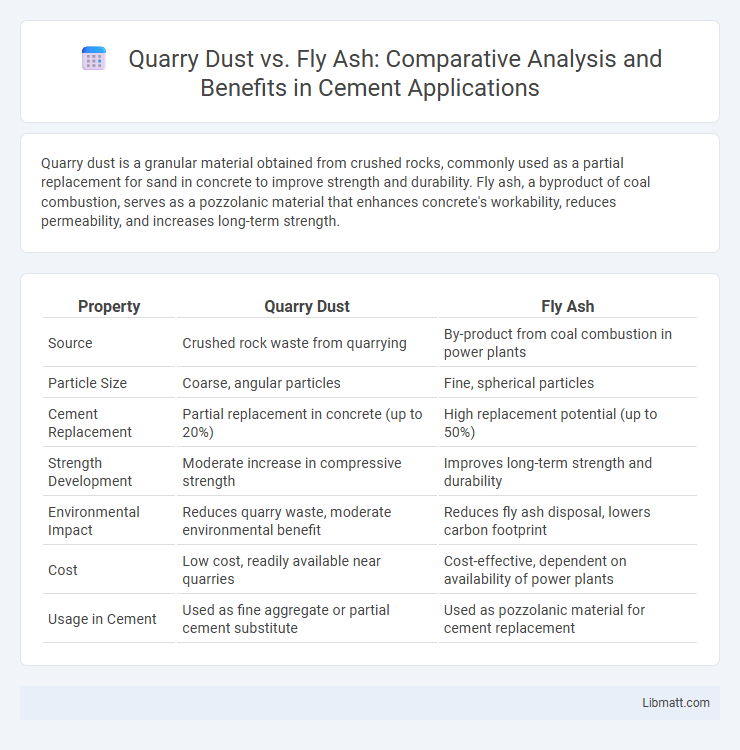

Quarry dust is a granular material obtained from crushed rocks, commonly used as a partial replacement for sand in concrete to improve strength and durability. Fly ash, a byproduct of coal combustion, serves as a pozzolanic material that enhances concrete's workability, reduces permeability, and increases long-term strength.

Table of Comparison

| Property | Quarry Dust | Fly Ash |

|---|---|---|

| Source | Crushed rock waste from quarrying | By-product from coal combustion in power plants |

| Particle Size | Coarse, angular particles | Fine, spherical particles |

| Cement Replacement | Partial replacement in concrete (up to 20%) | High replacement potential (up to 50%) |

| Strength Development | Moderate increase in compressive strength | Improves long-term strength and durability |

| Environmental Impact | Reduces quarry waste, moderate environmental benefit | Reduces fly ash disposal, lowers carbon footprint |

| Cost | Low cost, readily available near quarries | Cost-effective, dependent on availability of power plants |

| Usage in Cement | Used as fine aggregate or partial cement substitute | Used as pozzolanic material for cement replacement |

Introduction to Quarry Dust and Fly Ash

Quarry dust is a byproduct of the crushing process in stone quarrying, commonly used as a fine aggregate in concrete production due to its grainy texture and durability. Fly ash, a fine powder generated from coal combustion in thermal power plants, enhances concrete's strength and workability by acting as a supplementary cementitious material. Both materials contribute to sustainable construction by recycling industrial waste and reducing reliance on natural aggregates.

Chemical Composition Comparison

Quarry dust primarily consists of silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3), similar to natural sand but with higher angularity and fineness. Fly ash, a byproduct of coal combustion, contains a significant amount of silica, alumina, and calcium oxide (CaO), with its pozzolanic properties enhancing concrete strength and durability. Understanding the chemical composition differences between quarry dust and fly ash can help you optimize material selection for sustainable construction projects.

Physical Properties and Characteristics

Quarry dust exhibits a coarse texture with angular particles and higher density, enhancing its suitability for concrete aggregates due to improved interlocking and strength. Fly ash consists of fine, spherical particles with low density and pozzolanic properties, which contribute to improved workability and durability in concrete mixes. Understanding the physical properties of these materials enables you to select the optimal additive for specific construction applications requiring either enhanced mechanical strength or improved material flow.

Environmental Impact Assessment

Quarry dust and fly ash differ significantly in their environmental impact assessment, with fly ash offering a sustainable waste management solution by recycling industrial by-products and reducing landfill use. Quarry dust, sourced from natural rock crushing, poses risks such as dust pollution and habitat disruption during extraction. Your choice in construction materials can influence environmental footprints, favoring fly ash for lower carbon emissions and improved resource efficiency.

Applications in Construction Industry

Quarry dust and fly ash serve distinct but complementary roles in the construction industry, with quarry dust primarily used as a fine aggregate substitute in concrete and asphalt mixtures, enhancing strength and durability. Fly ash, a byproduct of coal combustion, is widely employed as a supplementary cementitious material that improves workability, reduces permeability, and increases long-term strength of concrete. Utilizing your choice between quarry dust and fly ash depends on specific project requirements, environmental considerations, and desired performance outcomes in structural applications.

Performance in Concrete Mixes

Quarry dust, composed mainly of fine crushed rock, enhances concrete by improving its density and strength due to its angular particle shape, leading to better interlocking and reduced voids. Fly ash, a byproduct of coal combustion, contributes to increased workability, reduced permeability, and long-term durability through its pozzolanic properties, which react with calcium hydroxide to form additional cementitious compounds. Choosing between quarry dust and fly ash for your concrete mixes depends on the desired performance characteristics, where quarry dust excels in mechanical strength and fly ash improves overall durability and sustainability.

Cost Analysis and Availability

Quarry dust is generally more cost-effective due to its abundant availability near construction sites, reducing transportation expenses compared to fly ash, which may require longer haul distances from thermal power plants. Fly ash costs fluctuate based on supply-demand dynamics and environmental regulations impacting its production and distribution. The consistent local availability of quarry dust ensures steady pricing, while fly ash pricing benefits from government incentives in some regions promoting its use as a sustainable material.

Advantages and Limitations

Quarry dust offers superior strength and durability when used as a fine aggregate in construction, enhancing concrete's compressive strength and making it environmentally beneficial by recycling mining waste. Fly ash improves workability, reduces permeability, and increases long-term strength of concrete, while also contributing to sustainability by utilizing industrial by-products from coal combustion. Limitations of quarry dust include potential variability in particle size and the need for proper curing, whereas fly ash's performance depends heavily on its type and source, with potential issues related to setting time and early-age strength.

Long-term Durability and Strength

Quarry dust enhances concrete's long-term durability and strength by improving density and reducing permeability, which protects structures from environmental degradation. Fly ash contributes to increased strength over time through pozzolanic reactions that fill microvoids and reduce calcium hydroxide content, resulting in improved resistance to chemical attacks. Your choice depends on the specific mix requirements and the desired balance between immediate strength gain and long-term performance.

Future Trends and Sustainable Alternatives

Quarry dust and fly ash are increasingly recognized for their potential in sustainable construction, with fly ash gaining traction due to its waste-origin and ability to reduce cement usage, lowering carbon emissions. Future trends indicate a rise in research optimizing the particle size and chemical composition of both materials to enhance concrete strength and durability while minimizing environmental impact. Your choice between quarry dust and fly ash will depend on project requirements and local availability, as the industry moves toward greener alternatives that promote circular economy principles.

Quarry dust vs Fly ash Infographic

libmatt.com

libmatt.com