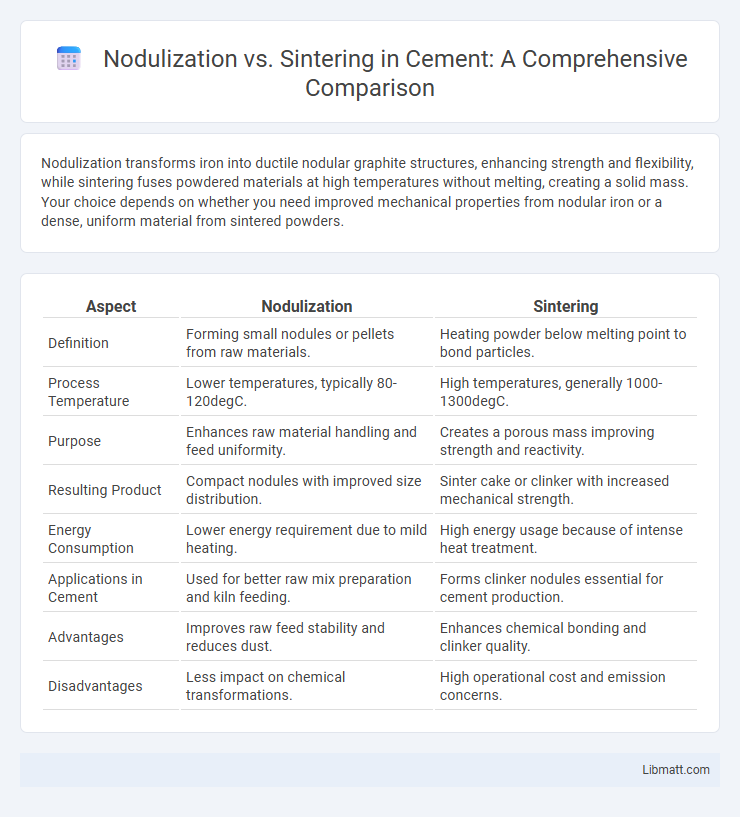

Nodulization transforms iron into ductile nodular graphite structures, enhancing strength and flexibility, while sintering fuses powdered materials at high temperatures without melting, creating a solid mass. Your choice depends on whether you need improved mechanical properties from nodular iron or a dense, uniform material from sintered powders.

Table of Comparison

| Aspect | Nodulization | Sintering |

|---|---|---|

| Definition | Forming small nodules or pellets from raw materials. | Heating powder below melting point to bond particles. |

| Process Temperature | Lower temperatures, typically 80-120degC. | High temperatures, generally 1000-1300degC. |

| Purpose | Enhances raw material handling and feed uniformity. | Creates a porous mass improving strength and reactivity. |

| Resulting Product | Compact nodules with improved size distribution. | Sinter cake or clinker with increased mechanical strength. |

| Energy Consumption | Lower energy requirement due to mild heating. | High energy usage because of intense heat treatment. |

| Applications in Cement | Used for better raw mix preparation and kiln feeding. | Forms clinker nodules essential for cement production. |

| Advantages | Improves raw feed stability and reduces dust. | Enhances chemical bonding and clinker quality. |

| Disadvantages | Less impact on chemical transformations. | High operational cost and emission concerns. |

Introduction to Nodulization and Sintering

Nodulization is a metallurgical process that transforms gray cast iron into ductile iron by adding nodulizing agents such as magnesium or cerium, enhancing mechanical properties like toughness and elasticity. Sintering is a heat treatment technique that compacts powdered metals at temperatures below their melting point to create solid, cohesive materials used in powder metallurgy and manufacturing complex components. Both processes improve material performance but differ fundamentally in their approach: nodulization modifies microstructure within molten metal, while sintering consolidates powders through diffusion and bonding.

Definition of Nodulization

Nodulization is a metallurgical process that transforms irregular cast iron microstructures into spherical graphite nodules, enhancing ductility and mechanical strength. It involves adding magnesium or cerium to molten iron to modify graphite morphology during solidification. This technique is crucial in producing ductile iron, which exhibits improved tensile properties compared to flake graphite iron produced by conventional sintering.

Definition of Sintering

Sintering is a high-temperature process that fuses powdered materials into a solid mass without melting them completely, commonly used in metallurgy and ceramics. This technique increases the strength and structural integrity of the material by promoting particle bonding through diffusion. Unlike nodulization, which improves ductility and toughness by forming spherical graphite nodules in cast iron, sintering primarily enhances density and mechanical properties of powdered components.

Key Differences Between Nodulization and Sintering

Nodulization is a heat treatment process used to improve the ductility and toughness of cast iron by transforming carbon into spherical graphite nodules, while sintering involves compacting and heating powdered materials below their melting point to form solid objects. The key differences between nodulization and sintering lie in their objectives and material forms: nodulization enhances mechanical properties of cast iron, whereas sintering creates components from metal powders through thermal bonding. Your choice between these processes depends on whether you need improved metal microstructure or fabrication of complex powdered metal parts.

Industrial Applications of Nodulization

Nodulization is crucial in the steel industry for producing ductile iron, enhancing mechanical properties and wear resistance in automotive components such as crankshafts and gears. It improves cast iron's tensile strength and impact resistance, enabling its use in heavy machinery and construction equipment. Compared to sintering, which is primarily used for powder metallurgy and manufacturing complex metal parts, nodulization specifically targets enhancing microstructure for superior performance in cast products.

Industrial Applications of Sintering

Sintering plays a critical role in manufacturing advanced ceramics, metal parts, and powder metallurgy components for automotive, aerospace, and electronics industries by enabling the creation of dense, high-strength materials from powdered substances. Industrial applications of sintering include producing cutting tools, brake pads, and structural parts where precise control over porosity, hardness, and dimensional stability is essential. Your understanding of the differences between nodulization and sintering highlights sintering's advantage in achieving complex shapes and enhanced material properties efficiently at scale.

Process Flow: Nodulization vs Sintering

Nodulization involves heating cast iron in a controlled furnace environment with magnesium to transform flake graphite into spherical nodules, enhancing ductility and strength. Sintering compacts and fuses powdered materials at high temperatures below their melting point, creating a dense solid with improved mechanical properties suitable for complex shapes. Both processes require precise thermal management, but nodulization focuses on microstructural modification, whereas sintering emphasizes particle bonding in powder metallurgy.

Advantages and Disadvantages of Nodulization

Nodulization improves ductility and strength in cast iron by transforming graphite flakes into spherical nodules, enhancing impact resistance and machinability. However, the process requires precise control of alloying elements like magnesium or cerium, increasing production complexity and cost. Despite these challenges, nodulized iron offers superior fatigue resistance and thermal conductivity compared to sintered materials, which often provide higher density but less toughness.

Advantages and Disadvantages of Sintering

Sintering offers advantages such as improved mechanical strength, enhanced material density, and the ability to produce complex shapes with minimal machining. However, disadvantages include high energy consumption, potential grain growth leading to brittleness, and limited applicability to certain materials with low melting points. Your choice between nodulization and sintering should consider these factors to match the specific requirements of your manufacturing process.

Choosing Between Nodulization and Sintering: Key Considerations

Choosing between nodulization and sintering depends on the desired microstructure and mechanical properties. Nodulization, typically used for ductile iron, enhances nodular graphite formation, improving ductility and toughness. Sintering, common in powder metallurgy, fuses powdered materials into a solid form, offering precise control over density and composition for specialized applications.

Nodulization vs Sintering Infographic

libmatt.com

libmatt.com