Pozzolana is a natural volcanic ash used as a supplementary cementitious material that enhances concrete durability and reduces permeability, while slag is a byproduct of iron production that improves concrete strength and resistance to chemical attacks. Understanding the differences between pozzolana and slag can help you select the right additive to optimize your construction project's performance and sustainability.

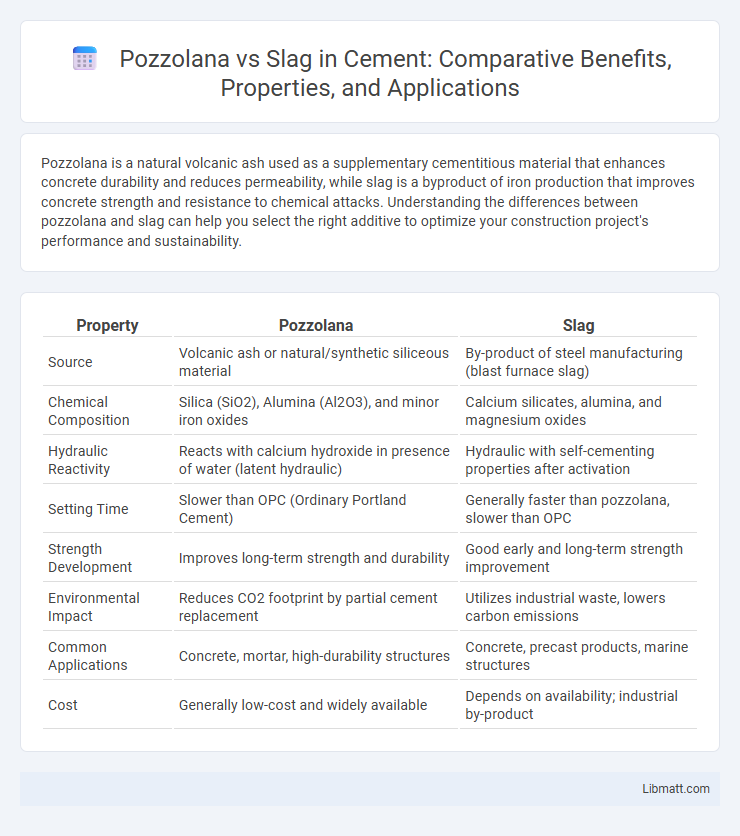

Table of Comparison

| Property | Pozzolana | Slag |

|---|---|---|

| Source | Volcanic ash or natural/synthetic siliceous material | By-product of steel manufacturing (blast furnace slag) |

| Chemical Composition | Silica (SiO2), Alumina (Al2O3), and minor iron oxides | Calcium silicates, alumina, and magnesium oxides |

| Hydraulic Reactivity | Reacts with calcium hydroxide in presence of water (latent hydraulic) | Hydraulic with self-cementing properties after activation |

| Setting Time | Slower than OPC (Ordinary Portland Cement) | Generally faster than pozzolana, slower than OPC |

| Strength Development | Improves long-term strength and durability | Good early and long-term strength improvement |

| Environmental Impact | Reduces CO2 footprint by partial cement replacement | Utilizes industrial waste, lowers carbon emissions |

| Common Applications | Concrete, mortar, high-durability structures | Concrete, precast products, marine structures |

| Cost | Generally low-cost and widely available | Depends on availability; industrial by-product |

Introduction to Pozzolana and Slag

Pozzolana is a natural or artificial volcanic ash containing siliceous and aluminous materials that react with calcium hydroxide at ordinary temperatures to form compounds possessing cementitious properties. Slag, a byproduct of metal smelting processes, primarily consists of calcium silicates and alumina, which contribute to its hydraulic properties when used as a supplementary cementitious material. Both pozzolana and slag enhance concrete durability and strength by improving microstructure and reducing permeability.

Defining Pozzolana: Types and Origins

Pozzolana is a natural or artificial volcanic ash composed mainly of siliceous and aluminous materials, which chemically reacts with calcium hydroxide to form compounds with cementitious properties. Common types include natural pozzolana from volcanic regions such as Italy and the Mediterranean, as well as artificial pozzolans like fly ash and silica fume produced from industrial byproducts. Understanding the origins and types of pozzolana is crucial for enhancing the durability and strength of your concrete mix when compared to slag-based materials.

What is Slag? Composition and Sources

Slag is a byproduct of metal smelting processes, primarily derived from the impurities separated from molten metals such as iron and steel. Its composition typically includes silicates, alumina, calcium oxide, and magnesium oxide, which contribute to its cementitious properties. Common sources of slag include blast furnace slag, granulated blast furnace slag, and steel slag, widely used as supplementary cementitious materials in concrete production.

Historical Uses of Pozzolana and Slag

Pozzolana, a volcanic ash used extensively by ancient Romans, enabled the creation of durable concrete structures like the Pantheon and aqueducts, showcasing its long-standing role in construction. Slag, a byproduct of metal smelting, has been repurposed historically in cement and road construction due to its excellent hydraulic properties and strength-enhancing capabilities. Your understanding of these materials highlights their critical contributions to architectural innovation and sustainable building practices throughout history.

Chemical Properties Comparison

Pozzolana primarily consists of silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3) with minor calcium oxide, exhibiting high pozzolanic activity through reaction with calcium hydroxide to form calcium silicate hydrate. Slag, specifically ground granulated blast furnace slag (GGBFS), contains higher calcium oxide (CaO) content alongside silica, alumina, and magnesia, contributing to its hydraulic properties and latent cementitious behavior. The lower calcium content in pozzolana results in slower strength gain, whereas slag's elevated CaO accelerates hydration, enhancing early strength development in blended cements.

Pozzolana vs Slag in Concrete Production

Pozzolana and slag both serve as supplementary cementitious materials in concrete production, enhancing durability and reducing environmental impact. Pozzolana, typically derived from volcanic ash, improves concrete's long-term strength and resistance to chemical attacks, while slag, a byproduct of steel manufacturing, contributes to increased late strength and reduced permeability. Your choice between pozzolana and slag depends on factors such as availability, desired strength development, and specific project requirements in concrete mix design.

Environmental Impact Assessment

Pozzolana and slag both serve as supplementary cementitious materials that reduce CO2 emissions by decreasing clinker content in concrete production. Pozzolana, often derived from volcanic ash, is naturally occurring and involves lower processing energy, resulting in a smaller carbon footprint compared to slag, which is a byproduct of steel manufacturing and requires energy-intensive beneficiation. Lifecycle assessments indicate pozzolana's renewable sourcing and lower greenhouse gas emissions make it a more sustainable choice in concrete sustainability strategies.

Advantages and Disadvantages

Pozzolana offers advantages such as improved durability, reduced permeability, and enhanced resistance to chemical attacks, but it may result in slower strength gain compared to ordinary cement. Slag enhances concrete workability, increases long-term strength, and provides better environmental sustainability by recycling industrial by-products; however, it can lead to delayed setting times and sensitivity to curing conditions. Both materials contribute to sustainable construction but require careful mix design to balance their benefits and limitations effectively.

Industry Applications: Case Studies

Pozzolana and slag are integral in the construction industry, with pozzolana commonly used in cement manufacturing for sustainable building projects such as India's rapid infrastructure expansion. Slag finds significant application in steel production waste recycling, exemplified by its use in the European Union where ground granulated blast furnace slag (GGBFS) enhances concrete durability in marine structures. Case studies from these regions demonstrate improved longevity and environmental benefits by substituting traditional cement components with pozzolana and slag.

Conclusion: Choosing Pozzolana or Slag

Choosing between pozzolana and slag depends on the specific project requirements, environmental considerations, and desired concrete properties. Pozzolana enhances durability and reduces permeability, making it ideal for structures exposed to aggressive environments, while slag improves strength and long-term performance with better resistance to sulfate attack. Evaluating factors such as local availability, cost-effectiveness, and sustainability goals helps determine the optimal supplementary cementitious material for construction applications.

Pozzolana vs Slag Infographic

libmatt.com

libmatt.com