A ball mill crushes materials by rotating a cylinder filled with steel balls, making it ideal for finely grinding ores and minerals, while a roller mill uses cylindrical rollers to crush or grind materials through compression, offering greater energy efficiency and better particle size control. Choosing between these mills depends on Your specific material properties and desired fineness, as ball mills handle smaller, harder particles, whereas roller mills excel in processing bulk materials with minimal heat generation.

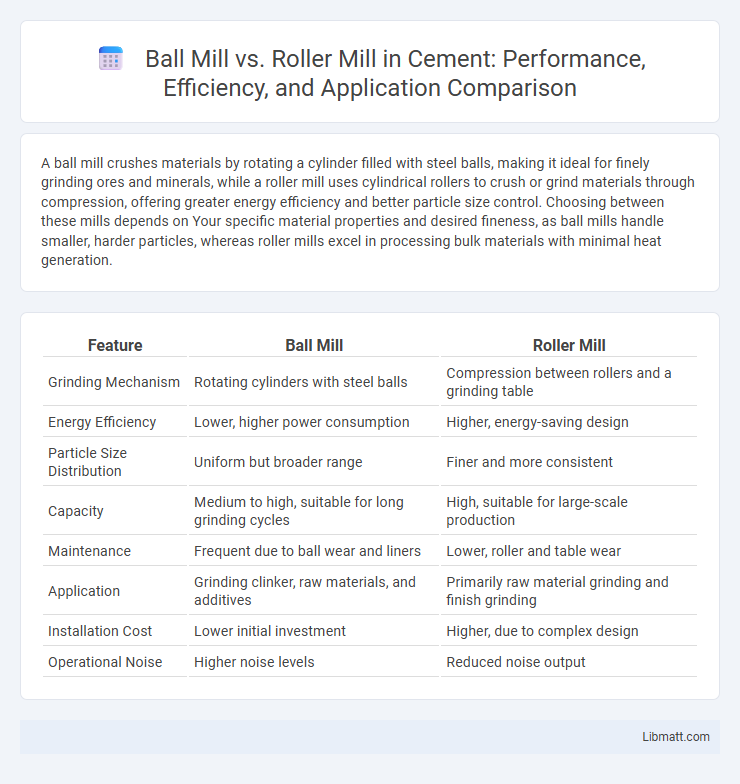

Table of Comparison

| Feature | Ball Mill | Roller Mill |

|---|---|---|

| Grinding Mechanism | Rotating cylinders with steel balls | Compression between rollers and a grinding table |

| Energy Efficiency | Lower, higher power consumption | Higher, energy-saving design |

| Particle Size Distribution | Uniform but broader range | Finer and more consistent |

| Capacity | Medium to high, suitable for long grinding cycles | High, suitable for large-scale production |

| Maintenance | Frequent due to ball wear and liners | Lower, roller and table wear |

| Application | Grinding clinker, raw materials, and additives | Primarily raw material grinding and finish grinding |

| Installation Cost | Lower initial investment | Higher, due to complex design |

| Operational Noise | Higher noise levels | Reduced noise output |

Introduction to Ball Mill and Roller Mill

Ball mills consist of a rotating cylinder filled with steel balls that grind materials through impact and attrition, widely used for fine grinding in mineral processing and cement manufacturing. Roller mills utilize cylindrical rollers that crush and pulverize materials through compression and shear forces, offering energy-efficient grinding especially in coal and grain processing. Both mills serve critical roles in size reduction but differ in mechanical design, operating principles, and suitable applications.

Working Principle: Ball Mill vs Roller Mill

Ball mills operate on a rotational principle where steel balls inside a rotating drum grind material through impact and attrition, effectively pulverizing hard and abrasive substances. Roller mills utilize cylindrical rollers that crush and grind material by compression and shear forces, providing efficient size reduction with lower energy consumption. The distinct mechanisms result in different particle size distributions, with ball mills producing finer powders and roller mills yielding more uniform granules.

Key Components and Design Differences

Ball mills feature rotating cylinders filled with steel or ceramic balls that grind material through impact and attrition, whereas roller mills use rotating rollers to crush and grind material by compression and shear. Key components of ball mills include the drum, grinding media, and trunnion bearings, while roller mills primarily consist of rolls, hydraulic systems, and grinding chambers. Your choice depends on factors like material hardness and desired fineness, as these design differences directly impact grinding efficiency and product uniformity.

Energy Efficiency Comparison

Ball mills typically consume more energy due to their rotational grinding mechanism, which requires significant power to crush materials. Roller mills, by contrast, employ compression and shear forces through rollers, resulting in lower energy consumption and higher energy efficiency. Studies indicate roller mills can reduce energy use by up to 30-50% compared to ball mills depending on the material and operational conditions.

Particle Size Distribution and Fineness

Ball mills produce finer particles with a more uniform particle size distribution due to their impact and attrition grinding mechanism, making them ideal for achieving high fineness in powdered materials. Roller mills generate coarser particles with a broader size distribution because they rely on compression and shear forces, which are better suited for grinding materials with less stringent fineness requirements. Your choice between the two depends on the desired particle size distribution and the fineness level needed for your specific application.

Maintenance and Operating Costs

Ball mills generally incur higher maintenance and operating costs due to their rotating drum design, which requires frequent replacement of liners and grinding media. Roller mills offer lower maintenance expenses with fewer moving parts and reduced energy consumption, translating to cost savings in your grinding operations. Choosing roller mills can optimize your budget by minimizing downtime and extending component life.

Applications in Various Industries

Ball mills excel in grinding and crushing applications across mining, cement production, and chemical industries due to their ability to handle hard and abrasive materials. Roller mills are preferred in the food, pharmaceutical, and mineral processing sectors for their energy efficiency and precise particle size control. Choosing between these mills depends on Your material characteristics and desired product specifications within each industry.

Environmental Impact and Sustainability

Ball mills consume more energy and produce higher CO2 emissions compared to roller mills, making them less environmentally friendly in industrial applications. Roller mills operate with greater energy efficiency, reducing overall carbon footprint and contributing to sustainable manufacturing processes. The lower noise levels and reduced dust emissions of roller mills also promote healthier working environments and comply better with environmental regulations.

Performance in Continuous and Batch Processing

Ball mills offer high grinding efficiency and uniform particle size distribution, making them ideal for batch processing where precise control is critical. Roller mills excel in continuous processing with superior throughput and energy efficiency due to their consistent compression and shear forces on the material. Performance optimization in both mills depends on feed characteristics, with roller mills providing better scalability for large-volume, continuous operations.

Choosing the Right Mill for Your Application

Selecting between a ball mill and a roller mill depends on the material properties and desired particle size. Ball mills excel in grinding hard, abrasive materials to fine powders, ideal for mineral processing and cement production. Roller mills offer higher efficiency for grinding softer materials with lower energy consumption, commonly used in grain milling and biomass processing.

Ball Mill vs Roller Mill Infographic

libmatt.com

libmatt.com