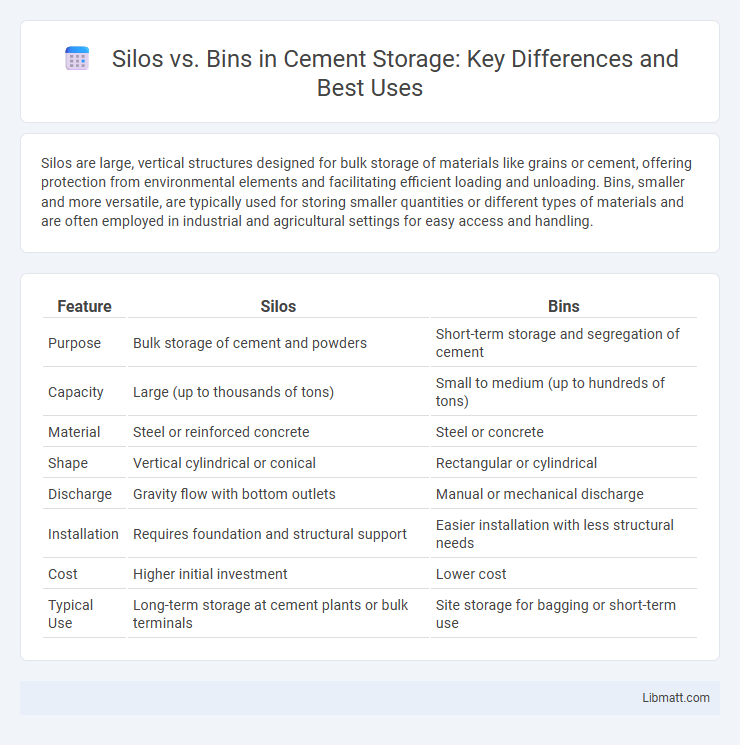

Silos are large, vertical structures designed for bulk storage of materials like grains or cement, offering protection from environmental elements and facilitating efficient loading and unloading. Bins, smaller and more versatile, are typically used for storing smaller quantities or different types of materials and are often employed in industrial and agricultural settings for easy access and handling.

Table of Comparison

| Feature | Silos | Bins |

|---|---|---|

| Purpose | Bulk storage of cement and powders | Short-term storage and segregation of cement |

| Capacity | Large (up to thousands of tons) | Small to medium (up to hundreds of tons) |

| Material | Steel or reinforced concrete | Steel or concrete |

| Shape | Vertical cylindrical or conical | Rectangular or cylindrical |

| Discharge | Gravity flow with bottom outlets | Manual or mechanical discharge |

| Installation | Requires foundation and structural support | Easier installation with less structural needs |

| Cost | Higher initial investment | Lower cost |

| Typical Use | Long-term storage at cement plants or bulk terminals | Site storage for bagging or short-term use |

Introduction to Silos and Bins

Silos and bins are essential storage structures used in agriculture and industry to store bulk materials like grain, feed, or raw materials. Silos are typically large, vertical structures designed for long-term storage and protection from environmental factors. Bins, on the other hand, are generally smaller containers used for temporary or short-term storage, offering easy access and handling for your material needs.

Defining Silos: Structure and Function

Silos are large, vertical storage structures designed primarily for bulk materials like grains, cement, or coal, offering controlled flow and protection from environmental factors. Their enclosed design prevents contamination and moisture ingress, making them ideal for long-term storage and maintaining product quality. Understanding the distinction in structure and function between silos and bins helps optimize material handling and storage solutions for your operational needs.

Understanding Bins: Types and Uses

Bins are commonly used storage containers designed for the temporary holding of granular or bulk materials and come in various types such as plastic, metal, and wooden bins. Typical uses include organizing small parts in warehouses, storing food ingredients in industrial kitchens, and collecting recyclable materials in residential or commercial settings. Their versatility and ease of access make bins an essential solution for efficient material handling and inventory management across multiple industries.

Key Differences Between Silos and Bins

Silos are large vertical structures designed for bulk storage of materials like grains, allowing for controlled airflow and moisture regulation, while bins are smaller containers ideal for short-term storage and easy access. Silos typically feature advanced mechanisms for loading and unloading, supporting high-capacity storage, whereas bins have simpler designs suited for manual handling. The key differences lie in their size, purpose, and functionality, with silos optimized for long-term preservation and large-scale operations, and bins tailored for convenience and smaller quantities.

Materials Commonly Stored in Silos vs Bins

Silos typically store bulk materials such as grains, cement, coal, and woodchips due to their large capacity and vertical design that facilitates gravity discharge. Bins are often used for smaller quantities or more granular materials like sand, gravel, plastics, and pellets, offering easier access and flexibility for handling. Selecting the right storage option depends on your specific material type, volume, and discharge requirements to ensure efficient handling and preservation.

Construction Materials and Designs

Silos are typically constructed from reinforced concrete or steel, featuring a cylindrical design that facilitates vertical storage and gravity-fed discharge ideal for bulk materials like grain or cement. Bins, often made from galvanized steel or plastic, come in various shapes including rectangular and conical-bottom designs optimized for easy access and smaller-scale storage. Your choice between silos and bins should consider the durability needs and material flow characteristics specific to your storage requirements.

Capacity and Size Comparison

Silos typically offer larger capacity options, ranging from several thousand to hundreds of thousands of cubic feet, making them ideal for bulk storage of grains or materials. Bins are generally smaller, with capacities suited for limited quantities and easier handling, often measured in hundreds to a few thousand cubic feet. Your choice between silos and bins will largely depend on the volume of material you need to store and the space available at your facility.

Advantages of Using Silos

Silos offer superior protection against weather elements and pests, ensuring optimal storage conditions for bulk materials like grains or cement. Their vertical design maximizes storage capacity in limited space, reducing the footprint compared to traditional bins. Additionally, silos facilitate efficient material flow and automated unloading, enhancing operational productivity in agricultural and industrial applications.

Benefits of Using Bins

Bins offer greater flexibility and accessibility for storing and handling smaller quantities of materials compared to silos, making them ideal for diverse operational needs. Their modular design allows easy installation, maintenance, and relocation, enhancing efficiency in storage management. You can optimize inventory control and reduce contamination risks, ensuring material quality and consistency.

Choosing Between Silos and Bins: Key Considerations

When choosing between silos and bins, consider factors such as storage capacity, material type, and environmental conditions. Silos are ideal for large-scale bulk storage of dry materials like grains, offering protection from weather and pests, while bins are suited for smaller quantities and easier access or transport. Evaluating cost, maintenance requirements, and specific handling needs ensures optimal selection for storage efficiency and material preservation.

Silos vs Bins Infographic

libmatt.com

libmatt.com