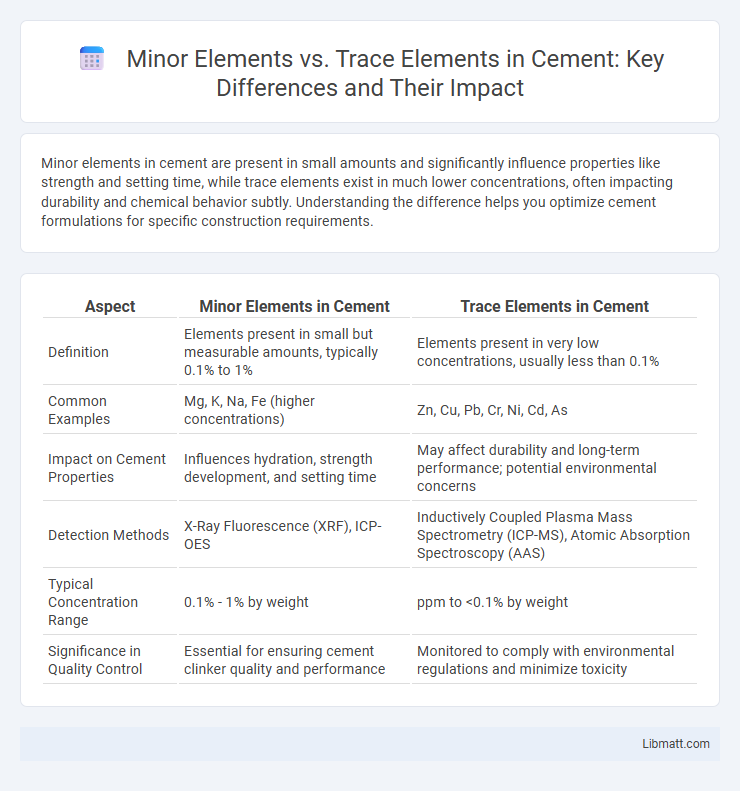

Minor elements in cement are present in small amounts and significantly influence properties like strength and setting time, while trace elements exist in much lower concentrations, often impacting durability and chemical behavior subtly. Understanding the difference helps you optimize cement formulations for specific construction requirements.

Table of Comparison

| Aspect | Minor Elements in Cement | Trace Elements in Cement |

|---|---|---|

| Definition | Elements present in small but measurable amounts, typically 0.1% to 1% | Elements present in very low concentrations, usually less than 0.1% |

| Common Examples | Mg, K, Na, Fe (higher concentrations) | Zn, Cu, Pb, Cr, Ni, Cd, As |

| Impact on Cement Properties | Influences hydration, strength development, and setting time | May affect durability and long-term performance; potential environmental concerns |

| Detection Methods | X-Ray Fluorescence (XRF), ICP-OES | Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Atomic Absorption Spectroscopy (AAS) |

| Typical Concentration Range | 0.1% - 1% by weight | ppm to <0.1% by weight |

| Significance in Quality Control | Essential for ensuring cement clinker quality and performance | Monitored to comply with environmental regulations and minimize toxicity |

Introduction to Cement Composition

Cement composition primarily comprises major compounds like calcium silicates, with minor elements and trace elements present in much smaller quantities but playing crucial roles in the material's properties. Minor elements such as aluminum, iron, and magnesium influence phase formation and hydration kinetics, while trace elements, including chromium and manganese, can affect cement's durability and setting time even at low concentrations. Understanding your cement's minor and trace element profile is essential for optimizing performance and ensuring quality control in construction applications.

Defining Minor Elements in Cement

Minor elements in cement refer to metallic elements present in concentrations typically between 0.1% and 1%, significantly affecting cement's physical and chemical properties without being major constituents. These elements, including iron, magnesium, and aluminum, influence clinker formation, hydration rates, and final cement strength. Understanding the role of minor elements helps you optimize cement composition for durability and performance in construction applications.

What Are Trace Elements in Cement?

Trace elements in cement refer to chemical elements present in very small quantities, typically less than 0.1% by weight, that can influence the cement's properties and performance. Unlike minor elements, which exist in slightly higher concentrations, trace elements such as chromium, nickel, and vanadium can affect setting time, color, and durability of the final concrete product. Understanding the role of these trace elements helps optimize Your cement formulation for enhanced quality and longevity.

Key Differences: Minor vs Trace Elements

Minor elements in cement are typically present in concentrations ranging from 0.1% to 1%, while trace elements occur at much lower levels, often below 0.1%. Minor elements such as calcium, silicon, aluminum, and iron play significant roles in clinker phases and influence the cement's mechanical properties and setting time. Trace elements, including chromium, nickel, and vanadium, usually appear as impurities and may affect environmental compliance and durability but have minimal impact on the fundamental chemistry of cement.

Typical Minor Elements Found in Cement

Typical minor elements found in cement include iron (Fe), aluminum (Al), and magnesium (Mg), which contribute to the color and strength properties of the final product. These elements exist in measurable quantities ranging from 0.1% to 5% by weight, significantly influencing the clinker's phase composition and hydration behavior. Understanding the concentration of minor elements is essential for optimizing cement quality and ensuring consistent performance in construction applications.

Common Trace Elements Detected in Cement

Common trace elements detected in cement include chromium, nickel, lead, and zinc, which originate from raw materials or fuel impurities during production. These minor elements, although present in small concentrations, influence cement quality and durability by affecting hydration processes and strength development. Understanding how these trace elements interact within your cement mix helps optimize performance and compliance with environmental standards.

Sources of Minor and Trace Elements

Minor and trace elements in cement primarily originate from raw materials such as limestone, clay, and shale, along with fuels used in the kiln process. These elements include iron, aluminum, and magnesium for minor elements while trace elements like chromium, manganese, and zinc arise from both raw materials and fuel impurities. Understanding the sources of these elements can help you control the quality and properties of the final cement product.

Effects on Cement Properties

Minor elements in cement, such as iron, aluminum, and magnesium, influence the clinker mineralogy and can enhance the strength and durability by stabilizing specific phases like alite and belite. Trace elements, including chromium, vanadium, and titanium, occur in very low concentrations but may affect setting time and color, sometimes leading to undesirable effects like increased permeability or reduced resistance to chemical attack. Understanding the precise composition and concentration of these elements is critical for optimizing cement performance in construction applications.

Environmental and Health Impacts

Minor elements in cement, such as manganese and chromium, occur in small amounts but can pose environmental risks through soil and water contamination if released improperly. Trace elements like arsenic and lead, present in even lower concentrations, have significant health impacts due to their toxicity and potential to bioaccumulate. Understanding the distinctions helps you manage regulatory compliance and minimize harmful exposure during cement production and application.

Analytical Methods for Detection

Analytical methods for detecting minor and trace elements in cement primarily include Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and X-ray Fluorescence (XRF) spectroscopy, which provide high sensitivity and accuracy for elemental analysis at low concentrations. Atomic Absorption Spectroscopy (AAS) and Laser Ablation ICP-MS are also employed to quantify trace elements like chromium, vanadium, and nickel that impact cement quality and durability. Precise detection of these elements ensures compliance with environmental standards and optimizes cement performance in construction applications.

Minor elements vs Trace elements (in cement) Infographic

libmatt.com

libmatt.com