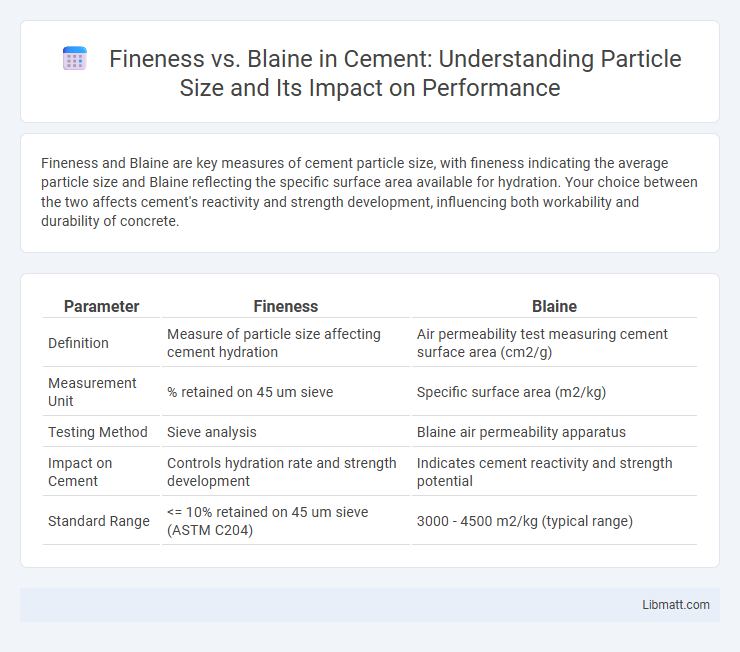

Fineness and Blaine are key measures of cement particle size, with fineness indicating the average particle size and Blaine reflecting the specific surface area available for hydration. Your choice between the two affects cement's reactivity and strength development, influencing both workability and durability of concrete.

Table of Comparison

| Parameter | Fineness | Blaine |

|---|---|---|

| Definition | Measure of particle size affecting cement hydration | Air permeability test measuring cement surface area (cm2/g) |

| Measurement Unit | % retained on 45 um sieve | Specific surface area (m2/kg) |

| Testing Method | Sieve analysis | Blaine air permeability apparatus |

| Impact on Cement | Controls hydration rate and strength development | Indicates cement reactivity and strength potential |

| Standard Range | <= 10% retained on 45 um sieve (ASTM C204) | 3000 - 4500 m2/kg (typical range) |

Introduction to Fineness and Blaine

Fineness and Blaine are critical parameters measuring the particle size and surface area of cement, influencing hydration rate and strength development. Fineness quantifies the particle size distribution, often assessed by sieving, while Blaine specifically measures the specific surface area through air permeability tests. Understanding these properties ensures optimal cement performance and durability in construction applications.

Understanding Fineness in Cement

Fineness in cement refers to the particle size distribution, directly impacting the rate of hydration and strength development in concrete. Blaine fineness, measured in cm2/g, quantifies the specific surface area of cement particles, indicating how finely ground the cement is. Understanding fineness helps you optimize cement performance by controlling setting time and enhancing durability in construction projects.

What Is the Blaine Method?

The Blaine method is a widely used technique to measure the fineness of powdered materials, particularly cement, by determining their specific surface area in square centimeters per gram. This method uses air permeability to assess how much surface area is exposed, which directly impacts the hydration rate and strength development in cement. Your understanding of Blaine fineness can help optimize particle size for improved performance in construction materials.

Key Differences Between Fineness and Blaine

Fineness measures the particle size distribution of cement using sieves, indicating how coarse or fine the material is, while Blaine specifically quantifies the specific surface area of cement particles through air permeability methods. The Blaine value, represented in cm2/g, directly affects cement hydration rate and strength development, whereas fineness primarily impacts the rate of reaction and workability. Understanding these key differences helps you accurately assess cement quality for optimized mix design and durability.

Importance of Cement Particle Size

Cement particle size significantly influences hydration rate, strength development, and durability of concrete. Fineness measured by Blaine surface area determines the specific surface area available for cement-water reaction, with higher Blaine values indicating finer particles and faster hydration. Optimizing fineness balances early strength gain and workability, reducing setting time without compromising long-term performance.

Testing Methods: Sieve Analysis vs Blaine Air Permeability

Fineness testing methods, such as Sieve Analysis and Blaine Air Permeability, provide critical insights into particle size distribution and surface area of powders. Sieve Analysis measures particle size by passing material through a series of mesh screens, offering a direct physical separation, while Blaine Air Permeability evaluates specific surface area by assessing airflow resistance through a compacted powder bed. Your choice between these tests hinges on the material characteristics and precision required for applications like cement quality control or pharmaceutical formulation.

Impact of Fineness and Blaine on Cement Performance

Fineness and Blaine surface area significantly influence cement hydration, strength development, and setting time. Higher fineness increases the surface area, accelerating hydration and improving early strength but may cause higher water demand and shrinkage. Your choice of cement fineness and Blaine should balance performance requirements with durability and workability considerations.

Industry Standards and Specifications

Industry standards for fineness and Blaine surface area play a critical role in evaluating cement particle size distribution and reactivity. Fineness is typically measured by the residue on a 45-micron sieve, with standards such as ASTM C204 specifying maximum allowable values to ensure adequate cement performance. Blaine air permeability tests quantify specific surface area in m2/kg, aligning with specifications like ASTM C204 and EN 196-6 to optimize hydration rates and strength development in concrete applications.

Challenges in Measuring Fineness and Blaine

Measuring fineness and Blaine presents challenges due to variations in particle size distribution and the sensitivity of testing equipment. Fineness often requires precise sieving or laser diffraction methods, while Blaine analysis relies on air permeability techniques, both affected by sample preparation and environmental conditions. Your accuracy in cement quality control depends on understanding these measurement limitations and ensuring standardized testing procedures.

Future Trends in Cement Fineness Measurement

Advancements in cement fineness measurement are moving towards digital and real-time monitoring technologies, such as laser diffraction and automated ultrasound-based systems, offering higher precision and repeatability compared to traditional Blaine air permeability methods. The integration of AI and machine learning algorithms enables predictive maintenance and process optimization, reducing variability in cement particle size distribution. Future trends emphasize the development of portable, inline sensors that provide immediate feedback for adaptive control in cement grinding, improving overall quality and energy efficiency in cement production.

Fineness vs Blaine Infographic

libmatt.com

libmatt.com