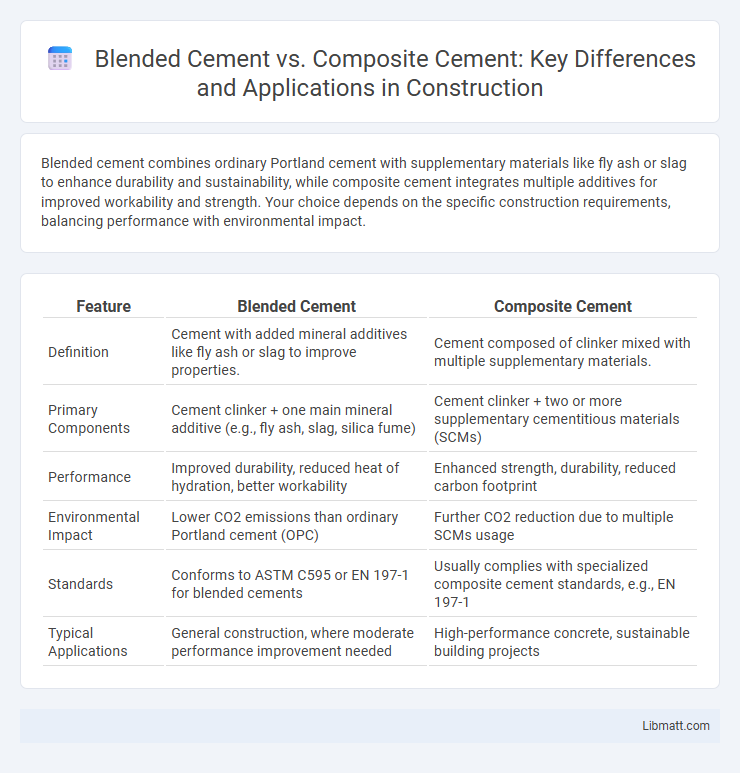

Blended cement combines ordinary Portland cement with supplementary materials like fly ash or slag to enhance durability and sustainability, while composite cement integrates multiple additives for improved workability and strength. Your choice depends on the specific construction requirements, balancing performance with environmental impact.

Table of Comparison

| Feature | Blended Cement | Composite Cement |

|---|---|---|

| Definition | Cement with added mineral additives like fly ash or slag to improve properties. | Cement composed of clinker mixed with multiple supplementary materials. |

| Primary Components | Cement clinker + one main mineral additive (e.g., fly ash, slag, silica fume) | Cement clinker + two or more supplementary cementitious materials (SCMs) |

| Performance | Improved durability, reduced heat of hydration, better workability | Enhanced strength, durability, reduced carbon footprint |

| Environmental Impact | Lower CO2 emissions than ordinary Portland cement (OPC) | Further CO2 reduction due to multiple SCMs usage |

| Standards | Conforms to ASTM C595 or EN 197-1 for blended cements | Usually complies with specialized composite cement standards, e.g., EN 197-1 |

| Typical Applications | General construction, where moderate performance improvement needed | High-performance concrete, sustainable building projects |

Introduction to Blended and Composite Cement

Blended cement incorporates supplementary materials like fly ash or slag to enhance durability and sustainability, reducing clinker content and carbon footprint. Composite cement combines multiple additives such as limestone and pozzolanic materials to improve workability and strength in concrete applications. Understanding the differences helps you select the optimal cement type for specific construction needs and environmental impact goals.

Composition and Key Ingredients

Blended cement primarily consists of ordinary Portland cement mixed with supplementary materials such as fly ash, slag, or silica fume to enhance durability and reduce environmental impact. Composite cement combines Portland cement clinker with a higher proportion of industrial by-products like slag and pozzolans, optimizing strength and sustainability. Your choice between the two depends on the desired performance characteristics and environmental considerations for specific construction projects.

Manufacturing Processes Compared

Blended cement is produced by mixing Portland cement clinker with supplementary cementitious materials such as fly ash, slag, or silica fume, typically during the grinding process. Composite cement involves the intergrinding of clinker with a higher proportion of mineral additives, resulting in a more homogeneous mixture with enhanced durability and sustainability properties. Both processes reduce clinker content, lowering CO2 emissions, but composite cement manufacturing often requires precise control of additive proportions to meet specific performance standards.

Physical and Chemical Properties

Blended cement incorporates industrial by-products such as fly ash or slag to enhance durability and reduce permeability, exhibiting improved sulfate resistance and moderate heat of hydration compared to ordinary Portland cement. Composite cement combines Portland cement clinker with multiple additives like limestone, fly ash, and slag, resulting in lower carbon emissions, enhanced workability, and balanced setting times, while maintaining adequate compressive strength. Both types present varying chemical compositions, with blended cement typically having higher alumina and silica content, and composite cement optimized for eco-friendly performance and structural stability.

Performance in Concrete Applications

Blended cement, containing fly ash, slag, or silica fume, enhances concrete durability by improving resistance to sulfate attack, alkali-silica reaction, and reducing permeability, resulting in longer service life in infrastructure projects. Composite cement incorporates additional mineral components in higher proportions, offering improved workability, reduced heat of hydration, and better environmental sustainability while maintaining comparable compressive strength. Both cements contribute significantly to sustainable construction, with blended cement favored for high-performance concrete in aggressive environments and composite cement preferred for large-scale construction requiring low carbon footprint and controlled setting times.

Environmental Impact and Sustainability

Blended cement incorporates industrial by-products like fly ash or slag, reducing clinker content and lowering CO2 emissions during production, making it more environmentally sustainable than ordinary Portland cement. Composite cement combines multiple supplementary materials, enhancing sustainability by improving durability and reducing the need for frequent repairs, which decreases resource consumption over the structure's lifecycle. Both cements contribute significantly to reducing the carbon footprint in construction through efficient use of industrial waste and decreased energy demand.

Cost Analysis and Availability

Blended cement generally offers lower cost efficiency due to partial replacement of Portland cement with industrial by-products like fly ash or slag, reducing raw material expenses and energy consumption. Composite cement, while similar in incorporating supplementary materials, may involve more diverse additives which can affect price variability based on supply chain stability and regional availability. Availability of blended cement is typically higher in regions with established industrial waste sources, whereas composite cement depends on broader raw material access, influencing procurement costs and market penetration.

Advantages of Blended Cement

Blended cement offers improved durability and enhanced resistance to chemical attacks, making it ideal for structures exposed to harsh environments. It reduces the carbon footprint by incorporating industrial by-products like fly ash or slag, contributing to sustainable construction practices. Your projects benefit from cost savings and improved workability due to the lower heat of hydration and reduced water demand of blended cement.

Benefits of Composite Cement

Composite cement offers enhanced durability and improved resistance to chemical attacks compared to blended cement, making it ideal for harsh environments. Its optimized mix with supplementary materials like fly ash or slag reduces carbon footprint and promotes sustainability in construction. Your projects benefit from better workability and long-term strength, ensuring both economic and environmental advantages.

Choosing the Right Cement for Your Project

Choosing the right cement for your project depends on the specific requirements of strength, durability, and environmental impact. Blended cement, which combines ordinary Portland cement with supplementary materials like fly ash or slag, offers improved durability and reduced carbon footprint, making it ideal for large infrastructure projects. Composite cement incorporates a wider range of industrial by-products and mineral additives, enhancing resistance to chemical attacks and making it suitable for specialized construction needs such as marine or chemical environments.

Blended cement vs Composite cement Infographic

libmatt.com

libmatt.com