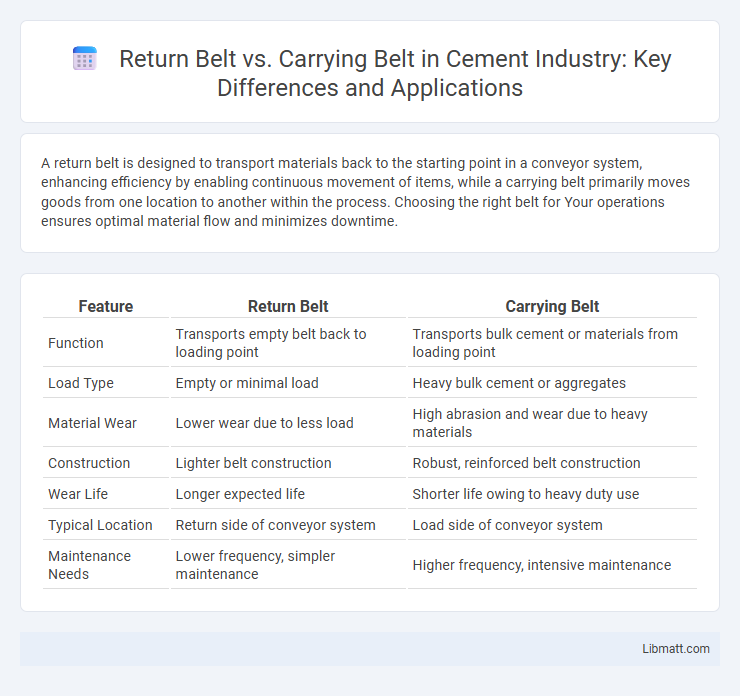

A return belt is designed to transport materials back to the starting point in a conveyor system, enhancing efficiency by enabling continuous movement of items, while a carrying belt primarily moves goods from one location to another within the process. Choosing the right belt for Your operations ensures optimal material flow and minimizes downtime.

Table of Comparison

| Feature | Return Belt | Carrying Belt |

|---|---|---|

| Function | Transports empty belt back to loading point | Transports bulk cement or materials from loading point |

| Load Type | Empty or minimal load | Heavy bulk cement or aggregates |

| Material Wear | Lower wear due to less load | High abrasion and wear due to heavy materials |

| Construction | Lighter belt construction | Robust, reinforced belt construction |

| Wear Life | Longer expected life | Shorter life owing to heavy duty use |

| Typical Location | Return side of conveyor system | Load side of conveyor system |

| Maintenance Needs | Lower frequency, simpler maintenance | Higher frequency, intensive maintenance |

Introduction to Conveyor Belt Systems

Return belts and carrying belts are essential components of conveyor belt systems, each serving distinct functions to ensure efficient material transportation. The carrying belt is responsible for moving the load from the loading point to the discharge area, designed to support and transport materials effectively. In contrast, the return belt travels beneath the carrying belt, providing a return path for the empty belt, reducing wear and maintaining system balance.

What is a Return Belt?

A Return Belt is a component of conveyor systems designed to carry the belt back to the starting point after it has transported materials on the top side. Unlike a Carrying Belt, which supports the load and moves products forward, the Return Belt operates underneath, minimizing wear and increasing system efficiency. Your conveyor's performance relies heavily on both belts functioning correctly to maintain smooth, continuous operation.

What is a Carrying Belt?

A Carrying Belt is a crucial component in conveyor systems designed to support and transport materials efficiently along the production line. Unlike a Return Belt, which primarily moves empty belt segments back to the loading point, the Carrying Belt directly carries bulk materials or products, ensuring smooth and consistent flow. Your choice between these belts affects operational efficiency, load capacity, and maintenance requirements in industrial processes.

Key Differences: Return Belt vs Carrying Belt

The key differences between a return belt and a carrying belt lie in their functions and design within conveyor systems. A carrying belt transports materials or products from one point to another on the conveyor, bearing the load on its upper surface, while a return belt moves beneath the conveyor frame, returning the empty belt to the loading point. Return belts are typically designed to minimize friction and wear as they operate without a load, whereas carrying belts require durability and traction to handle the conveyed materials efficiently.

Material Handling Efficiency Comparison

Return belts and carrying belts are critical components in conveyor systems, with carrying belts designed to transport bulk materials effectively, often featuring durable, abrasion-resistant materials like PVC or rubber for high load capacity and longevity. Return belts, typically lighter and made from materials such as fabric or low-friction synthetic compounds, focus on minimizing energy consumption and reducing wear by efficiently guiding the belt back to the loading point. The material handling efficiency of carrying belts exceeds return belts in terms of weight capacity and transfer speed, while return belts optimize system energy use and maintenance costs by ensuring smooth, low-resistance movement.

Durability and Wear Considerations

Return belts typically experience higher tension and abrasive contact, requiring materials with superior tensile strength and abrasion resistance to ensure durability. Carrying belts, designed primarily for load support and transport, benefit from construction that emphasizes wear resistance and flexibility to withstand continuous friction and load variation. Selecting the appropriate belt depends on balancing tensile load capacity against surface wear properties to optimize lifespan and performance in specific conveyor system applications.

Maintenance Requirements for Each Belt

Return belts require less frequent maintenance due to lower load and slower speeds, often involving routine inspections for belt alignment and cleaning to prevent buildup. Carrying belts experience higher material loads and increased wear, necessitating more regular checks for belt tension, damage, and roller function to ensure efficient operation. Your maintenance strategy should consider these differences to optimize belt lifespan and minimize downtime.

Cost Implications: Return vs Carrying Belts

Return belts typically have lower cost implications compared to carrying belts due to their simpler construction and reduced load requirements, primarily designed to transport the belt back to the pulley system. Carrying belts, however, incur higher expenses because they must support the entire weight of the conveyed material, necessitating stronger materials and more robust design features. Evaluating your operational needs carefully will help determine the most cost-effective choice between return and carrying belts.

Application Suitability and Industry Use

Return belts are ideal for recycling materials within manufacturing processes where continuous loop conveyor systems are used, making them suitable for industries such as packaging and automotive assembly lines. Carrying belts excel in transporting goods over distances and varying elevations, commonly found in logistics, mining, and food processing sectors. Your choice depends on whether the priority is material return within a closed system or efficient product movement across production stages.

Choosing the Right Belt for Your Conveyor System

Selecting the right belt for your conveyor system depends on the specific application requirements, such as load type, belt speed, and environmental conditions. Return belts are designed for the underside of the conveyor, optimized for minimal friction and energy efficiency, while carrying belts handle heavier loads on the top run, requiring durable materials and strong tensile strength. Understanding these distinctions ensures you choose the belt that maximizes your conveyor system's performance and longevity.

Return Belt vs Carrying Belt Infographic

libmatt.com

libmatt.com