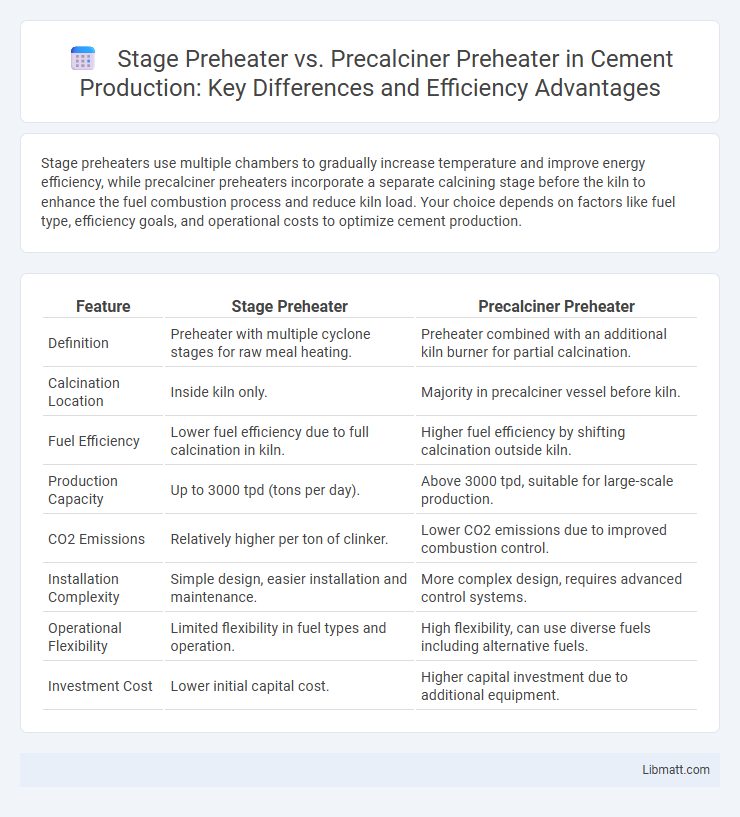

Stage preheaters use multiple chambers to gradually increase temperature and improve energy efficiency, while precalciner preheaters incorporate a separate calcining stage before the kiln to enhance the fuel combustion process and reduce kiln load. Your choice depends on factors like fuel type, efficiency goals, and operational costs to optimize cement production.

Table of Comparison

| Feature | Stage Preheater | Precalciner Preheater |

|---|---|---|

| Definition | Preheater with multiple cyclone stages for raw meal heating. | Preheater combined with an additional kiln burner for partial calcination. |

| Calcination Location | Inside kiln only. | Majority in precalciner vessel before kiln. |

| Fuel Efficiency | Lower fuel efficiency due to full calcination in kiln. | Higher fuel efficiency by shifting calcination outside kiln. |

| Production Capacity | Up to 3000 tpd (tons per day). | Above 3000 tpd, suitable for large-scale production. |

| CO2 Emissions | Relatively higher per ton of clinker. | Lower CO2 emissions due to improved combustion control. |

| Installation Complexity | Simple design, easier installation and maintenance. | More complex design, requires advanced control systems. |

| Operational Flexibility | Limited flexibility in fuel types and operation. | High flexibility, can use diverse fuels including alternative fuels. |

| Investment Cost | Lower initial capital cost. | Higher capital investment due to additional equipment. |

Introduction to Cement Preheating Technologies

Stage preheaters use multiple cyclones arranged vertically to recover heat from kiln exhaust gases, significantly enhancing energy efficiency in cement production. Precalciner preheaters incorporate an additional combustion chamber before the kiln, enabling more complete fuel combustion and reducing overall emissions. Both technologies improve thermal efficiency but precalciner preheaters offer greater fuel flexibility and higher production capacity.

Overview of Stage Preheater Systems

Stage preheater systems optimize cement production by sequentially heating raw materials through multiple cyclone stages, enhancing thermal efficiency and reducing fuel consumption. These systems typically operate at lower temperatures compared to precalciner preheaters, which introduce additional fuel combustion zones to increase calcination rates. The modular design of stage preheaters allows gradual material processing, improving gas-solid contact and promoting energy savings within the kiln system.

Understanding Precalciner Preheater Systems

Precalciner preheater systems enhance cement production efficiency by introducing fuel combustion in a separate calcining zone, allowing more complete calcination before entering the kiln. Unlike stage preheaters, which rely solely on heat exchange through multiple cyclone stages, precalciner systems achieve higher thermal efficiency and reduced fuel consumption by controlling the precalciner temperature independently. This results in optimized clinker quality and lower overall energy costs in cement manufacturing.

Key Design Differences: Stage Preheater vs Precalciner

Stage preheaters typically involve a multi-stage cyclonic system where raw materials pass through sequential heating zones, optimizing heat exchange and reducing fuel consumption. Precalciner preheaters integrate a separate calcination chamber allowing partial calcination before entering the kiln, resulting in higher production capacity and improved fuel efficiency. The key design differences lie in the calcination approach--stage preheaters rely on progressive heating stages while precalciner preheaters incorporate an independent calciner to enhance process control and energy utilization.

Energy Efficiency Comparison

Stage preheaters and precalciner preheaters differ significantly in energy efficiency, with precalciner preheaters typically offering superior fuel utilization by enabling more thorough combustion and higher thermal efficiency. The precalciner design allows a larger portion of the fuel to be burned in the precalciner, reducing fuel consumption and improving heat transfer before the material enters the kiln. Your operational costs can decrease as precalciner preheaters optimize energy use, enhancing overall process efficiency compared to conventional stage preheaters.

Impact on Clinker Quality

Stage preheaters provide consistent temperature control, enhancing clinker formation by promoting uniform heat distribution and reducing incomplete reactions. Precalciner preheaters improve fuel efficiency and allow higher fuel substitution rates, resulting in more stable combustion and better chemical composition in the clinker. Your choice between these systems directly affects the thermal profile during the calcination process, critically impacting the overall clinker quality.

Environmental Considerations

Stage preheaters generally produce lower NOx emissions due to better temperature control during fuel combustion, helping to reduce air pollution. Precalciner preheaters, while more fuel-efficient, may require advanced emission control systems to comply with stricter environmental regulations. Your choice between these preheaters should consider both the environmental impact and regulatory requirements to minimize your facility's carbon footprint.

Operational Flexibility and Control

Stage preheaters offer enhanced operational flexibility by allowing precise temperature control at each combustion stage, optimizing fuel usage and reducing emissions. Precalciner preheaters improve control by separating the calcination process from the kiln, enabling independent adjustment of fuel input and airflow for better combustion stability. You can achieve more reliable management of your kiln operation with the precalciner preheater's modular design, especially in variable load conditions.

Cost Implications and ROI

Stage preheater systems typically involve lower initial capital investment compared to precalciner preheaters, but they may lead to higher operational costs due to less efficient fuel usage and longer kiln residence times. Precalciner preheaters, though capital intensive, offer superior thermal efficiency and fuel savings by enabling more complete fuel combustion prior to the kiln, resulting in faster clinker production and reduced energy consumption. The return on investment (ROI) for precalciner preheaters is generally higher over the long term, driven by lower operational costs, enhanced production capacity, and improved kiln performance.

Future Trends in Preheating Technologies

Stage preheaters are evolving with improved modular designs that enhance heat recovery and reduce energy consumption, promoting sustainability in cement production. Precalciner preheaters integrate advanced burner technologies and real-time process control systems, optimizing combustion efficiency and lowering CO2 emissions. Innovations in sensor integration and AI-driven analytics are set to revolutionize both technologies, enabling predictive maintenance and maximizing operational performance.

Stage preheater vs Precalciner preheater Infographic

libmatt.com

libmatt.com