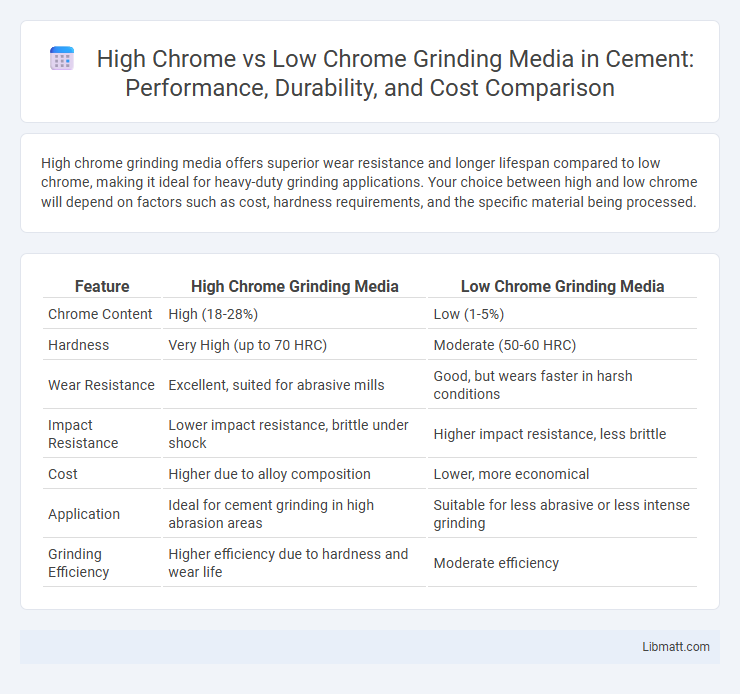

High chrome grinding media offers superior wear resistance and longer lifespan compared to low chrome, making it ideal for heavy-duty grinding applications. Your choice between high and low chrome will depend on factors such as cost, hardness requirements, and the specific material being processed.

Table of Comparison

| Feature | High Chrome Grinding Media | Low Chrome Grinding Media |

|---|---|---|

| Chrome Content | High (18-28%) | Low (1-5%) |

| Hardness | Very High (up to 70 HRC) | Moderate (50-60 HRC) |

| Wear Resistance | Excellent, suited for abrasive mills | Good, but wears faster in harsh conditions |

| Impact Resistance | Lower impact resistance, brittle under shock | Higher impact resistance, less brittle |

| Cost | Higher due to alloy composition | Lower, more economical |

| Application | Ideal for cement grinding in high abrasion areas | Suitable for less abrasive or less intense grinding |

| Grinding Efficiency | Higher efficiency due to hardness and wear life | Moderate efficiency |

Introduction to Grinding Media Types

High chrome grinding media consists of steel balls with chromium content typically ranging from 10% to 30%, offering superior hardness, wear resistance, and durability for grinding applications. Low chrome grinding media contains less than 5% chromium, providing a cost-effective option with moderate toughness and reduced abrasion resistance. Selection between high and low chrome grinding media depends on specific milling requirements, including material hardness, mill speed, and the desired balance between grinding efficiency and media lifespan.

Composition of High Chrome vs. Low Chrome Grinding Media

High chrome grinding media typically contains 10-30% chromium, which enhances its hardness and wear resistance, making it ideal for applications requiring extended durability. Low chrome grinding media generally has less than 5% chromium, resulting in lower hardness but improved toughness for impact resistance in less abrasive conditions. Understanding the composition difference helps optimize your grinding process by selecting media that balances abrasion resistance and impact strength based on your specific operational needs.

Hardness and Wear Resistance Comparison

High chrome grinding media typically exhibit hardness values ranging from 62 to 66 HRC, providing superior wear resistance compared to low chrome grinding media, which usually have hardness levels between 58 to 62 HRC. The higher chromium content (above 10%) in high chrome media leads to the formation of hard carbides, significantly enhancing abrasion resistance and extending lifespan in mineral processing applications. Low chrome grinding media, with lower carbide content, demonstrate reduced hardness and are more prone to surface wear and deformation under intense grinding conditions.

Performance in Milling Applications

High chrome grinding media offers superior hardness and wear resistance compared to low chrome variants, resulting in longer service life and enhanced performance in milling applications. Its higher chromium content reduces abrasion and corrosion, making it ideal for intensive grinding processes in industries like cement and mining. Your milling efficiency improves as high chrome media maintains consistent grinding action, minimizing downtime and operational costs.

Cost Analysis: High Chrome vs. Low Chrome

High chrome grinding media requires a higher upfront investment due to its chromium content, which enhances wear resistance and prolongs lifespan, reducing replacement frequency and downtime costs. Low chrome grinding media offers a lower initial purchase price but often leads to increased wear and more frequent replacements, raising overall operational expenses. Your decision should weigh the long-term cost savings of high chrome against the short-term affordability of low chrome to optimize grinding efficiency and budget.

Corrosion Resistance and Longevity

High chrome grinding media exhibits superior corrosion resistance due to its higher chromium content, typically ranging from 15% to 30%, which forms a robust chromium oxide layer protecting against oxidative wear and chemical attack. Low chrome grinding media, with chromium levels below 10%, tends to corrode faster when exposed to harsh environments, resulting in reduced longevity and frequent replacement. Selecting the right grinding media enhances your equipment's lifespan and operational efficiency by minimizing corrosion-related downtime.

Impact on Milling Efficiency and Output Quality

High chrome grinding media offers superior wear resistance and hardness compared to low chrome media, resulting in enhanced milling efficiency and longer service life. This increased durability reduces media consumption and contamination, thereby improving the output quality by producing finer, more consistent particle sizes. Choosing the right chrome content in your grinding media directly influences grinding performance, energy use, and the overall quality of the milled product.

Environmental and Safety Considerations

High chrome grinding media offers superior durability and reduced contamination, leading to less frequent replacement and lower environmental waste compared to low chrome options. Low chrome grinding media may pose increased risks of metal leaching and corrosion, potentially impacting workplace safety and surrounding ecosystems. Your choice of high chrome media helps enhance operational safety while supporting environmentally responsible grinding practices.

Application Suitability: Industry-Specific Uses

High chrome grinding media excel in industries such as mining and cement, where high abrasion resistance and durability are critical for grinding hard ore and clinker materials. Low chrome grinding media suit applications in coal, minerals, and chemical industries where a softer media prevents excessive wear on equipment and reduces contamination of the product. Your choice between high and low chrome grinding media depends on the specific wear conditions and chemical compatibility required by your industry.

Choosing the Right Grinding Media for Your Needs

High chrome grinding media offers superior hardness, wear resistance, and longer lifespan compared to low chrome variants, making it ideal for industries requiring high durability, such as mining and cement production. Low chrome grinding media, while less expensive, provides adequate performance for lighter applications and is more cost-effective for operations with shorter wear cycles. Selecting the right grinding media depends on balancing your operational needs, budget constraints, and the material being processed to optimize grinding efficiency and reduce downtime.

High Chrome Grinding Media vs Low Chrome Infographic

libmatt.com

libmatt.com