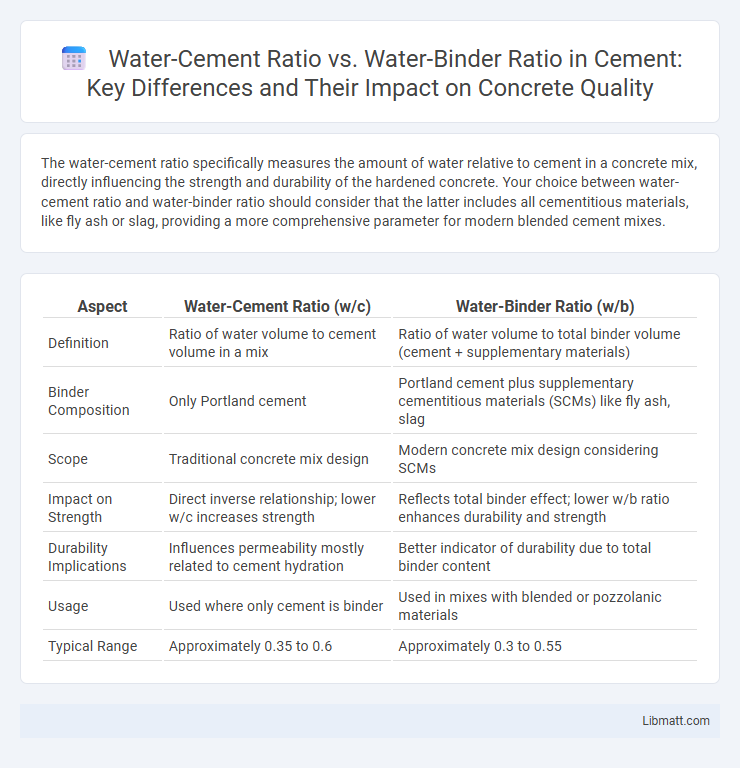

The water-cement ratio specifically measures the amount of water relative to cement in a concrete mix, directly influencing the strength and durability of the hardened concrete. Your choice between water-cement ratio and water-binder ratio should consider that the latter includes all cementitious materials, like fly ash or slag, providing a more comprehensive parameter for modern blended cement mixes.

Table of Comparison

| Aspect | Water-Cement Ratio (w/c) | Water-Binder Ratio (w/b) |

|---|---|---|

| Definition | Ratio of water volume to cement volume in a mix | Ratio of water volume to total binder volume (cement + supplementary materials) |

| Binder Composition | Only Portland cement | Portland cement plus supplementary cementitious materials (SCMs) like fly ash, slag |

| Scope | Traditional concrete mix design | Modern concrete mix design considering SCMs |

| Impact on Strength | Direct inverse relationship; lower w/c increases strength | Reflects total binder effect; lower w/b ratio enhances durability and strength |

| Durability Implications | Influences permeability mostly related to cement hydration | Better indicator of durability due to total binder content |

| Usage | Used where only cement is binder | Used in mixes with blended or pozzolanic materials |

| Typical Range | Approximately 0.35 to 0.6 | Approximately 0.3 to 0.55 |

Introduction to Water-Cement and Water-Binder Ratios

The water-cement ratio specifically compares the weight of water to the weight of cement in a concrete mix, directly affecting the strength and durability of the concrete. The water-binder ratio expands this concept by including all cementitious materials, such as fly ash and slag, providing a more comprehensive measure for mix design and performance prediction. Understanding the distinction between these ratios is crucial for optimizing concrete mix proportions to achieve desired mechanical properties and durability in construction projects.

Definitions: Water-Cement Ratio Explained

The water-cement ratio refers specifically to the weight of water divided by the weight of cement in a concrete mix, directly influencing the strength and durability of the final product. The water-binder ratio expands this concept by including all cementitious materials, such as fly ash and slag, in the denominator, providing a more comprehensive measure for mixes with supplementary materials. Your understanding of these ratios helps optimize concrete mix design for better performance and longevity.

What is Water-Binder Ratio?

Water-binder ratio refers to the proportion of water to the total binder content, including cement and supplementary materials like fly ash or slag, in a concrete mix. This ratio is crucial for determining the workability, strength, and durability of concrete, as it influences the hydration process and the microstructure of the hardened material. Understanding your water-binder ratio helps optimize mix design for improved performance and sustainability.

Key Differences Between Water-Cement and Water-Binder Ratios

The water-cement ratio specifically compares the weight of water to the weight of cement in a concrete mix, while the water-binder ratio includes both cement and supplementary cementitious materials like fly ash or slag in the binder fraction. The water-cement ratio is critical for controlling concrete strength and durability, whereas the water-binder ratio provides a more comprehensive measure for modern concrete mixes incorporating supplementary materials, impacting workability and long-term performance. Understanding these differences is essential for optimizing mix designs to achieve desired mechanical properties and durability standards in various construction applications.

Impact on Concrete Workability

Water-cement ratio directly influences concrete workability by controlling the amount of water available for cement hydration and mixture fluidity, where higher ratios enhance workability but may reduce strength. Water-binder ratio, encompassing both cement and supplementary cementitious materials, provides a more comprehensive measure affecting consistency and durability, as additional binders alter the water demand and flow characteristics. Understanding the distinction allows you to optimize concrete mixtures for improved workability without compromising structural performance.

Effects on Concrete Strength and Durability

Water-cement ratio directly influences concrete strength and durability by controlling the porosity and hydration process; lower ratios generally yield higher strength and improved resistance to weathering and chemical attacks. Water-binder ratio extends this concept by including supplementary cementitious materials like fly ash or slag, enhancing concrete's long-term durability and reducing permeability. Understanding the difference allows you to optimize mix designs for stronger, more durable concrete tailored to specific construction requirements.

Modern Binders and Supplementary Cementitious Materials

Water-cement ratio traditionally measures the amount of water relative to cement, while the water-binder ratio includes all cementitious materials, such as modern binders and supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume. Using the water-binder ratio better reflects the hydration process and strength development in concrete with SCMs, optimizing mix design for durability and performance. Understanding these ratios helps you tailor concrete mixes to achieve improved workability, reduced permeability, and enhanced long-term strength in sustainable construction projects.

Water-Binder Ratio in High-Performance Concrete

Water-binder ratio in high-performance concrete critically influences strength, durability, and workability, where a lower ratio typically enhances compressive strength and reduces permeability compared to the traditional water-cement ratio. Unlike the water-cement ratio that measures only cement, the water-binder ratio accounts for all cementitious materials including fly ash and slag, providing a more comprehensive assessment for mix design optimization. You can achieve superior performance by carefully adjusting the water-binder ratio to balance hydration while minimizing voids and microcracks in the concrete matrix.

Best Practices in Concrete Mix Design

The water-cement ratio specifically measures the proportion of water to cement, directly influencing concrete strength and durability, while the water-binder ratio includes supplementary cementitious materials like fly ash or slag, affecting workability and long-term performance. Best practices in concrete mix design emphasize optimizing the water-binder ratio to ensure proper hydration and minimize permeability, improving concrete's resistance to cracking and environmental damage. Your concrete mix will achieve enhanced durability and strength by carefully balancing these ratios according to project specifications and material properties.

Choosing Between Water-Cement and Water-Binder Ratios

Choosing between water-cement ratio and water-binder ratio depends on the type of binder used in the concrete mix, with water-binder ratio including supplementary cementitious materials like fly ash or slag in addition to cement. Water-binder ratio provides a more accurate measure of the mix's workability and durability when using blended binders, as it accounts for all hydraulic components contributing to hydration. For plain cement mixes, water-cement ratio remains sufficient, but for multi-component binders, water-binder ratio optimizes strength and longevity predictions.

Water-cement ratio vs Water-binder ratio Infographic

libmatt.com

libmatt.com