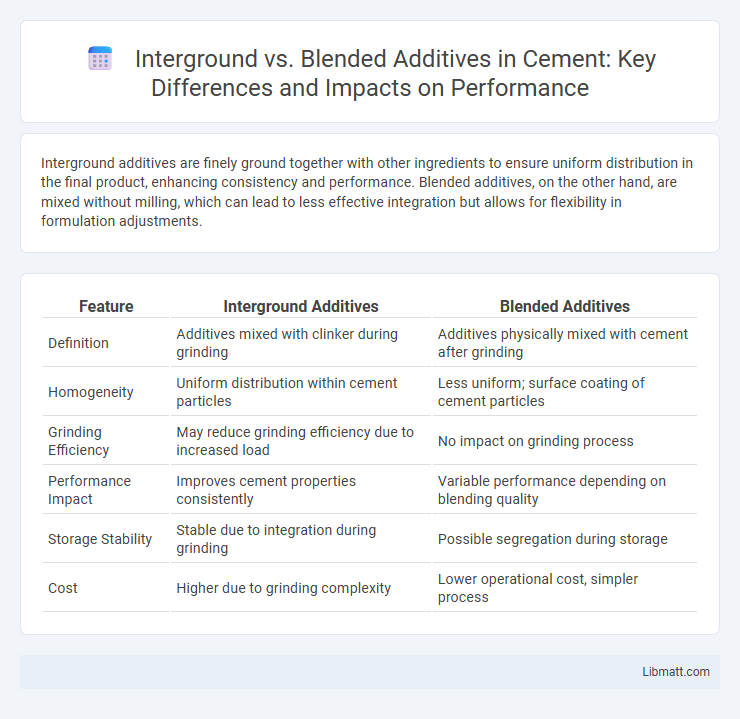

Interground additives are finely ground together with other ingredients to ensure uniform distribution in the final product, enhancing consistency and performance. Blended additives, on the other hand, are mixed without milling, which can lead to less effective integration but allows for flexibility in formulation adjustments.

Table of Comparison

| Feature | Interground Additives | Blended Additives |

|---|---|---|

| Definition | Additives mixed with clinker during grinding | Additives physically mixed with cement after grinding |

| Homogeneity | Uniform distribution within cement particles | Less uniform; surface coating of cement particles |

| Grinding Efficiency | May reduce grinding efficiency due to increased load | No impact on grinding process |

| Performance Impact | Improves cement properties consistently | Variable performance depending on blending quality |

| Storage Stability | Stable due to integration during grinding | Possible segregation during storage |

| Cost | Higher due to grinding complexity | Lower operational cost, simpler process |

Introduction to Cement Additives

Interground additives are mixed directly with clinker during the final grinding process, enhancing cement properties by improving workability and strength without altering the grinding efficiency. Blended additives, typically supplementary cementitious materials like fly ash, slag, or silica fume, are mixed with cement after production to optimize durability, reduce carbon footprint, and enhance specific performance characteristics. Both additive types play critical roles in customizing cement for diverse construction requirements and environmental sustainability.

Understanding Interground Additives

Interground additives are incorporated directly into the base material during the grinding process, resulting in a uniform dispersion throughout the final product. This method enhances the additive's effectiveness by ensuring consistent distribution at a microscopic level, improving performance attributes such as dispersion, stability, and processing characteristics. Compared to blended additives, interground additives provide superior integration, reducing the risk of segregation and improving the overall quality and durability of paints, coatings, and inks.

Exploring Blended Additives

Blended additives combine multiple chemical components to enhance performance characteristics such as durability, flexibility, and resistance in construction materials. These additives optimize the mixing and curing processes by improving the uniformity and compatibility of ingredients within the blend. Your choice of blended additives can significantly impact the overall quality and longevity of the final product, making them a vital consideration in material formulation.

Key Differences: Interground vs Blended Additives

Interground additives are incorporated directly into cement clinker during the grinding process, ensuring uniform distribution and enhancing cement performance consistency. Blended additives, on the other hand, are mixed with cement after grinding, offering flexibility to tailor cement properties for specific applications but potentially causing variability in quality. Interground additives typically improve early strength and durability more efficiently, while blended additives allow for cost-effective modifications and specialty formulations.

Impact on Cement Performance and Quality

Interground additives integrate directly into the cement during grinding, enhancing particle distribution and improving early strength development by increasing surface area and hydration kinetics. Blended additives, mixed post-grinding, allow for tailored performance adjustments but may reduce uniformity, potentially affecting long-term durability and consistency. Your selection between interground and blended additives influences cement's setting time, strength gain, and overall performance, making it crucial for specific construction requirements.

Cost Considerations and Economic Implications

Interground additives typically offer lower production costs due to reduced grinding and energy requirements compared to blended additives, which involve separate manufacturing and mixing processes. The economic implications favor interground additives in large-scale cement production, as they streamline operations and minimize inventory management expenses. However, blended additives allow for more precise customization, potentially improving product performance and reducing lifecycle costs despite higher upfront investment.

Environmental Benefits and Sustainability

Interground additives are produced by grinding minerals directly with cement clinker, resulting in lower energy consumption and reduced CO2 emissions compared to blended additives, which require separate processing of supplementary materials like fly ash or slag. This streamlined production process enhances resource efficiency and minimizes landfill waste, contributing to a smaller carbon footprint. By integrating interground additives, the construction industry supports sustainable manufacturing practices and promotes eco-friendly concrete solutions.

Compatibility with Supplementary Cementitious Materials

Interground additives demonstrate high compatibility with Supplementary Cementitious Materials (SCMs) by being finely milled together with clinker and SCMs, ensuring a uniform particle distribution and enhanced hydration kinetics. Blended additives, mixed separately with SCMs, may exhibit less homogeneity, potentially leading to variable setting times and strength development. Cement formulations with interground additives often show improved mechanical properties and durability when combined with SCMs such as fly ash, slag, or silica fume.

Industry Applications and Case Studies

Interground additives enhance material properties through fine particle integration, making them ideal for concrete production and coatings, where improved strength and durability are critical. Blended additives combine multiple agents to optimize performance in applications like plastics and adhesives, offering tailored solutions for flexibility and chemical resistance. Case studies in construction reveal interground additives providing superior cement hydration, while blended additives demonstrate enhanced polymer elasticity in automotive manufacturing.

Future Trends in Cement Additive Technology

Future trends in cement additive technology emphasize the integration of interground and blended additives to enhance performance and sustainability. Interground additives, such as limestone or slag, are finely milled together with clinker, improving workability and reducing CO2 emissions, while blended additives like fly ash or silica fume are combined post-grinding to optimize strength and durability. Advancements in nanotechnology and AI-driven mix designs are expected to tailor additive combinations for specific applications, driving innovation in eco-friendly cement production.

Interground vs Blended additives Infographic

libmatt.com

libmatt.com