Cement paste consists solely of cement and water, forming the binding agent that hardens over time, while mortar combines cement paste with fine aggregates like sand to provide improved strength and workability for masonry applications. Your choice between cement paste and mortar depends on whether you need a bonding material (mortar) or a pure adhesive (cement paste) for construction projects.

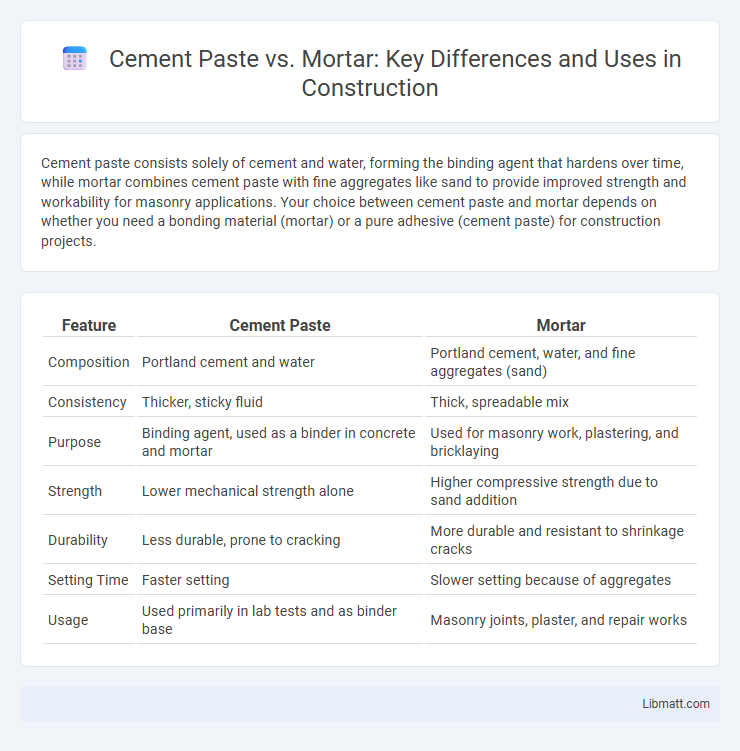

Table of Comparison

| Feature | Cement Paste | Mortar |

|---|---|---|

| Composition | Portland cement and water | Portland cement, water, and fine aggregates (sand) |

| Consistency | Thicker, sticky fluid | Thick, spreadable mix |

| Purpose | Binding agent, used as a binder in concrete and mortar | Used for masonry work, plastering, and bricklaying |

| Strength | Lower mechanical strength alone | Higher compressive strength due to sand addition |

| Durability | Less durable, prone to cracking | More durable and resistant to shrinkage cracks |

| Setting Time | Faster setting | Slower setting because of aggregates |

| Usage | Used primarily in lab tests and as binder base | Masonry joints, plaster, and repair works |

Introduction to Cement Paste and Mortar

Cement paste is a mixture of cement and water that forms the binding matrix in concrete, while mortar consists of cement paste combined with fine aggregates like sand. The composition of cement paste is primarily responsible for the hydration process and strength development, whereas mortar provides workability and structural support for masonry units. Understanding the differences in their material properties is essential for optimizing construction applications and durability.

Composition Differences

Cement paste is composed of cement and water only, forming the binder that hardens over time. Mortar contains cement paste combined with fine aggregates like sand, improving workability and strength. The inclusion of sand in mortar significantly alters its texture, setting time, and structural properties compared to pure cement paste.

Cement Paste: Properties and Uses

Cement paste is a hydrated mixture of cement and water, characterized by its smooth consistency and high adhesive properties, serving as the binding phase in concrete and mortar. Its strength development, workability, and setting time are crucial for determining the overall durability and performance of construction materials. Cement paste is extensively used in making concrete, repairing cracks, and as a bonding agent in various masonry applications where strong adhesion is required.

Mortar: Properties and Applications

Mortar is a workable mixture of cement paste, sand, and water that enhances bonding and durability in masonry construction. Its properties include excellent adhesion, moderate compressive strength, and resistance to weathering, making it ideal for laying bricks, blocks, and stones. You can rely on mortar for applications requiring strong bonding and structural integrity in walls, pavements, and repair works.

Mixing Process and Techniques

The mixing process for cement paste involves combining cement and water into a smooth, lump-free consistency, ensuring proper hydration and chemical bonding. Mortar mixing incorporates cement paste with sand, requiring techniques like blending dry components before adding water to achieve uniform texture and workability. Your choice of mixing method impacts the strength and application quality of the resulting construction material.

Strength and Durability Comparison

Cement paste consists solely of cement and water, resulting in higher strength but lower durability due to increased shrinkage and cracking. Mortar combines cement paste with fine aggregates, enhancing durability and reducing shrinkage, though it offers slightly lower compressive strength. Your choice depends on whether maximum strength or long-term durability is the priority for the application.

Workability and Setting Time

Cement paste consists of cement and water, offering higher workability but faster setting time compared to mortar, which includes sand in its mix. The inclusion of fine aggregates in mortar reduces workability due to increased internal friction but extends setting time by slowing hydration. Optimal adjustment of water-cement ratio in cement paste and aggregate grading in mortar significantly influences both workability and setting behavior.

Common Usage Scenarios

Cement paste serves as the binder in concrete and mortar, providing adhesion and strength, primarily used for laboratory testing and as a base for mortar mixtures. Mortar, a blend of cement paste and sand, is commonly used in bricklaying, plastering, and masonry repairs to bond building units and fill gaps. Understanding the distinction between cement paste and mortar helps you choose the right material for specific construction and renovation tasks.

Advantages and Limitations

Cement paste, composed solely of cement and water, offers superior bonding strength and minimizes voids, making it ideal for precise applications requiring maximum adhesion. Mortar incorporates fine aggregates like sand, enhancing workability, dimensional stability, and resistance to shrinkage, which benefits masonry construction. However, cement paste's limited flexibility and higher shrinkage risk restrict its use in structural assemblies, while mortar's lower compressive strength compared to pure cement paste can limit load-bearing capacity.

Choosing Between Cement Paste and Mortar

Choosing between cement paste and mortar depends on your project's structural requirements and durability needs; cement paste consists solely of cement and water, offering strong adhesion but limited workability. Mortar includes sand, which improves strength, reduces shrinkage, and enhances bonding between masonry units, making it ideal for bricklaying and blockwork. Your decision should consider the balance between strength, workability, and the specific application to ensure optimal construction performance.

Cement paste vs Mortar Infographic

libmatt.com

libmatt.com