A bucket elevator efficiently transports bulk materials vertically by using a series of buckets attached to a belt or chain, making it ideal for lifting heavy loads with minimal space. In contrast, a belt conveyor moves materials horizontally or at a slight incline on a continuous belt, offering flexibility for long-distance transport and easier maintenance.

Table of Comparison

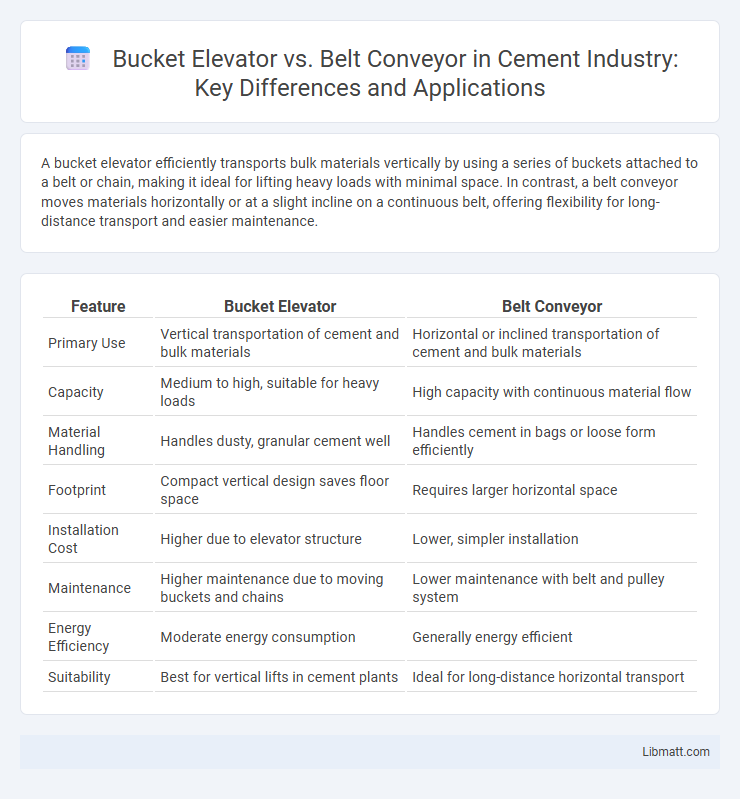

| Feature | Bucket Elevator | Belt Conveyor |

|---|---|---|

| Primary Use | Vertical transportation of cement and bulk materials | Horizontal or inclined transportation of cement and bulk materials |

| Capacity | Medium to high, suitable for heavy loads | High capacity with continuous material flow |

| Material Handling | Handles dusty, granular cement well | Handles cement in bags or loose form efficiently |

| Footprint | Compact vertical design saves floor space | Requires larger horizontal space |

| Installation Cost | Higher due to elevator structure | Lower, simpler installation |

| Maintenance | Higher maintenance due to moving buckets and chains | Lower maintenance with belt and pulley system |

| Energy Efficiency | Moderate energy consumption | Generally energy efficient |

| Suitability | Best for vertical lifts in cement plants | Ideal for long-distance horizontal transport |

Introduction to Material Handling Systems

Bucket elevators and belt conveyors are essential material handling systems designed to transport bulk materials efficiently within industrial environments. Bucket elevators excel at vertical lifting of granular or powdered substances, ensuring minimal spillage and consistent flow, whereas belt conveyors provide continuous horizontal or inclined transportation suited for a wide range of materials. Your choice between these systems depends on specific operational needs such as height, capacity, and material characteristics.

Overview of Bucket Elevators

Bucket elevators are vertical lifting devices designed to transport bulk materials such as grains, powders, and pellets efficiently between different heights. They consist of a series of buckets attached to a belt or chain that moves continuously, allowing for high-capacity and consistent material flow. Your choice of a bucket elevator ensures space-saving vertical conveyance with minimal product degradation compared to horizontal belt conveyors.

Overview of Belt Conveyors

Belt conveyors consist of a continuous loop of material, usually rubber or synthetic fabric, that moves along pulleys to transport bulk goods or materials efficiently over long distances. Their design offers versatility in handling various load types and sizes, combined with smooth operation and low maintenance requirements. Belt conveyors excel in industries such as mining, manufacturing, and agriculture for their ability to transfer large quantities of material with consistent speed and controlled flow.

Key Differences Between Bucket Elevators and Belt Conveyors

Bucket elevators are designed for vertical lifting of bulk materials with high efficiency and minimal spillage, using a series of buckets attached to a belt or chain. Belt conveyors are ideal for transporting materials horizontally or at a slight incline over long distances, providing continuous movement with smooth handling. Your choice depends on the material's required direction and height of transport, as well as factors like speed, capacity, and space availability.

Application Suitability: Bucket Elevator vs Belt Conveyor

Bucket elevators excel in vertical material handling, particularly for bulk materials like grains, minerals, and powders, where space constraints demand steep or vertical lifts. Belt conveyors are more suitable for horizontal or gently inclined transportation over longer distances and can handle a broad range of materials, including packages, boxes, and bulk commodities. Selecting between bucket elevators and belt conveyors depends on factors such as elevation change, material type, throughput requirements, and installation space.

Space and Layout Considerations

Bucket elevators require a vertical layout, making them ideal for limited floor space and facilities with height availability, while belt conveyors need more horizontal space due to their length and gentle incline. The compact footprint of bucket elevators reduces the overall plant layout, optimizing space utilization in multi-level operations. Belt conveyors provide greater flexibility in routing materials over long distances and around obstacles within sprawling or irregular layouts.

Maintenance and Operational Costs Comparison

Bucket elevators typically require higher maintenance due to frequent inspections of buckets, belts, and pulleys, with parts prone to wear and tear under heavy loads. Belt conveyors often have lower operational costs, benefiting from simpler design and easier access to belts and rollers for routine maintenance. Cost efficiency depends on material type, throughput volume, and operational environment, influencing equipment longevity and replacement frequency.

Safety Aspects of Both Conveying Systems

Bucket elevators offer enhanced safety by enclosing materials within vertical casings, reducing dust emissions and minimizing exposure to moving parts, which decreases the risk of workplace injuries. Belt conveyors, while more open, benefit from guardrails and emergency stop mechanisms, but their horizontal design can pose trip hazards and increased dust dispersion. Understanding these safety aspects helps you select the optimal conveying system to protect workers and maintain compliance with industrial safety standards.

Energy Efficiency and Performance

Bucket elevators generally offer higher energy efficiency and superior performance in vertical material handling compared to belt conveyors, especially for lifting bulk solids over significant heights. Their enclosed design minimizes material spillage and reduces power consumption by using gravity to assist material movement, which contrasts with belt conveyors that often require more power to maintain belt tension and friction over long distances. Choosing a bucket elevator can enhance Your operational efficiency by decreasing downtime and maintenance costs while optimizing energy use.

Choosing the Right Solution for Your Material Handling Needs

Bucket elevators excel in vertical lifting of bulk materials with minimal spillage, making them ideal for confined spaces and heavy loads. Belt conveyors offer versatile horizontal or inclined transport with gentle handling, suitable for long distances and continuous flow. Your choice depends on factors such as material type, distance, elevation, and space constraints to optimize efficiency and cost-effectiveness.

Bucket Elevator vs Belt Conveyor Infographic

libmatt.com

libmatt.com