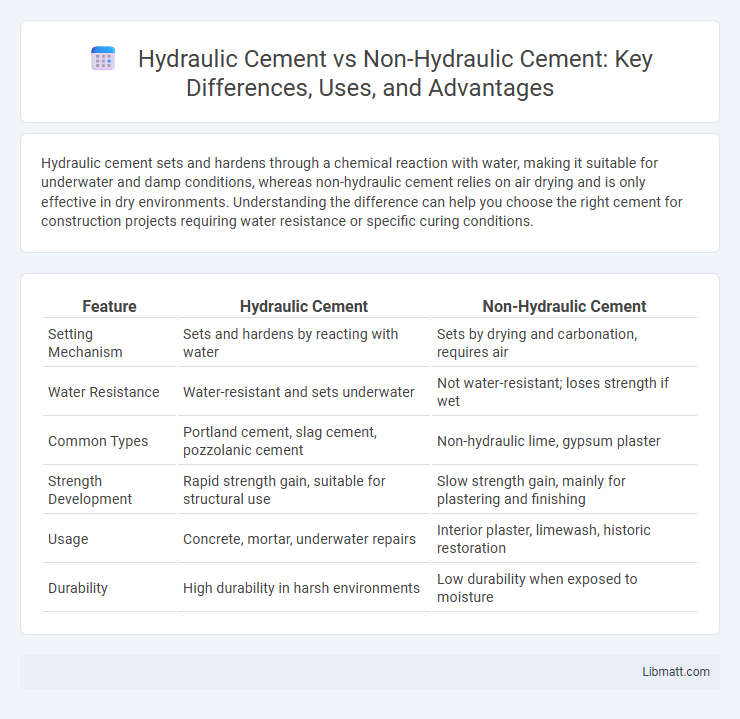

Hydraulic cement sets and hardens through a chemical reaction with water, making it suitable for underwater and damp conditions, whereas non-hydraulic cement relies on air drying and is only effective in dry environments. Understanding the difference can help you choose the right cement for construction projects requiring water resistance or specific curing conditions.

Table of Comparison

| Feature | Hydraulic Cement | Non-Hydraulic Cement |

|---|---|---|

| Setting Mechanism | Sets and hardens by reacting with water | Sets by drying and carbonation, requires air |

| Water Resistance | Water-resistant and sets underwater | Not water-resistant; loses strength if wet |

| Common Types | Portland cement, slag cement, pozzolanic cement | Non-hydraulic lime, gypsum plaster |

| Strength Development | Rapid strength gain, suitable for structural use | Slow strength gain, mainly for plastering and finishing |

| Usage | Concrete, mortar, underwater repairs | Interior plaster, limewash, historic restoration |

| Durability | High durability in harsh environments | Low durability when exposed to moisture |

Introduction to Hydraulic and Non-Hydraulic Cement

Hydraulic cement sets and hardens through a chemical reaction with water, allowing it to cure underwater or in wet conditions, making it ideal for foundations and underwater structures. Non-hydraulic cement, such as lime-based cement, hardens by reacting with carbon dioxide from the air and requires dry conditions to set properly, limiting its use primarily to above-ground applications. Understanding the distinction between hydraulic and non-hydraulic cement helps you choose the right material for your construction or repair projects based on environmental exposure and performance needs.

Composition and Chemical Properties

Hydraulic cement contains compounds such as calcium silicates and aluminates that react chemically with water to form a hard, water-resistant matrix. Non-hydraulic cement primarily consists of calcium carbonate or lime, which hardens by carbonation through exposure to carbon dioxide in the air rather than water. The chemical properties of hydraulic cement allow it to set and cure underwater, whereas non-hydraulic cement requires air curing and is not suitable for wet environments.

Setting and Hardening Mechanisms

Hydraulic cement sets and hardens through a chemical reaction with water, forming a durable, water-resistant bond even underwater. Non-hydraulic cement relies on air drying and carbonation to harden, making it unsuitable for wet conditions. Understanding these different setting and hardening mechanisms is crucial for selecting the right cement for your construction needs.

Historical Development and Usage

Hydraulic cement, developed in ancient Rome, sets and hardens through a chemical reaction with water, allowing it to cure underwater and in damp conditions, making it ideal for structures like aqueducts and bridges. Non-hydraulic cement, used in early civilizations like Egypt and Mesopotamia, hardens primarily by drying and is unsuitable for wet environments, limiting its application mainly to indoor and above-ground construction. Understanding these differences in historical development and usage helps you choose the appropriate cement type for specific building conditions and durability requirements.

Key Differences Between Hydraulic and Non-Hydraulic Cement

Hydraulic cement sets and hardens through a chemical reaction with water, enabling it to cure even underwater, while non-hydraulic cement requires air moisture to harden. Hydraulic cement's composition typically includes compounds like tricalcium silicate and dicalcium silicate, providing resistance to water and durability in wet conditions. Non-hydraulic cement, such as lime-based cement, offers slower setting times and lower water resistance, making it suitable for dry environments or applications where breathability is essential.

Performance in Wet and Dry Conditions

Hydraulic cement sets and hardens through a chemical reaction with water, maintaining strength and durability in both wet and dry conditions. Non-hydraulic cement relies on air drying to harden, losing strength when exposed to moisture or submerged environments. Consequently, hydraulic cement is preferred for underwater or damp applications due to its superior water resistance and consistent performance.

Common Applications in Construction

Hydraulic cement is widely used in construction projects requiring rapid setting and water resistance, such as foundations, underwater structures, and repairing concrete surfaces exposed to moisture. Non-hydraulic cement, which hardens through air drying, is typically applied in interior works like plastering, masonry, and decorative finishes where exposure to water is minimal. Understanding the difference helps you select the appropriate cement type for durability and performance in specific construction environments.

Advantages of Hydraulic Cement

Hydraulic cement sets and hardens through a chemical reaction with water, allowing it to cure underwater and in damp conditions, unlike non-hydraulic cement which requires air to dry. Its durability and resistance to moisture make hydraulic cement ideal for construction projects such as foundations, water tanks, and sewage systems. The superior strength and quick setting time of hydraulic cement ensure long-lasting structural integrity in diverse environmental conditions.

Limitations of Non-Hydraulic Cement

Non-hydraulic cement requires exposure to air to set and cannot harden underwater, significantly limiting its use in moist or submerged conditions. Its susceptibility to water damage and low durability in wet environments restricts applications primarily to dry, sheltered structures. You should avoid non-hydraulic cement for projects involving constant water exposure or heavy moisture to ensure structural integrity.

Choosing the Right Cement for Your Project

Hydraulic cement sets and hardens through a chemical reaction with water, making it ideal for underwater or high-moisture environments, as it maintains strength even when fully submerged. Non-hydraulic cement, such as lime plaster, requires air to cure and is best suited for dry conditions where moisture exposure is minimal. Selecting the appropriate cement depends on project requirements, exposure conditions, and desired durability, with hydraulic cement favored for infrastructure and repair work involving water contact.

Hydraulic cement vs Non-hydraulic cement Infographic

libmatt.com

libmatt.com