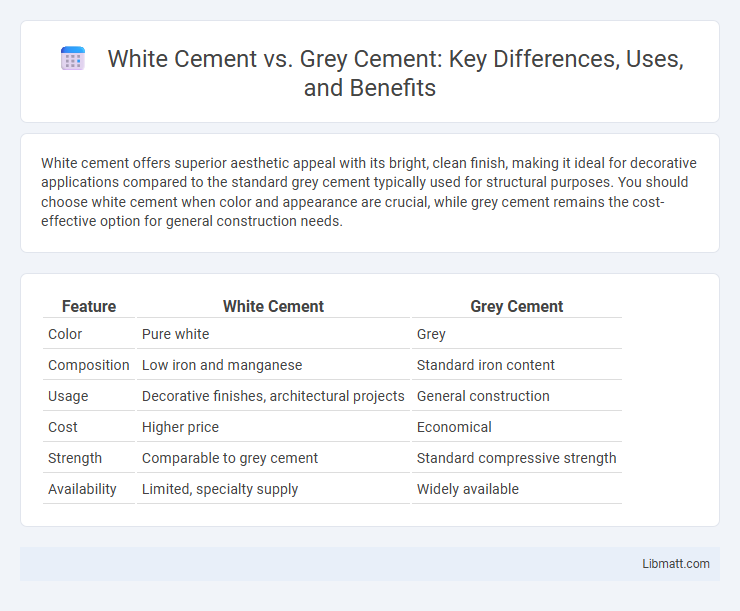

White cement offers superior aesthetic appeal with its bright, clean finish, making it ideal for decorative applications compared to the standard grey cement typically used for structural purposes. You should choose white cement when color and appearance are crucial, while grey cement remains the cost-effective option for general construction needs.

Table of Comparison

| Feature | White Cement | Grey Cement |

|---|---|---|

| Color | Pure white | Grey |

| Composition | Low iron and manganese | Standard iron content |

| Usage | Decorative finishes, architectural projects | General construction |

| Cost | Higher price | Economical |

| Strength | Comparable to grey cement | Standard compressive strength |

| Availability | Limited, specialty supply | Widely available |

Introduction to White Cement vs Grey Cement

White cement, known for its high purity and reflective properties, is primarily used in decorative and architectural projects requiring bright, clean finishes. Grey cement, the most common type of Portland cement, offers robust strength and durability suitable for structural applications and general construction. Your choice between white and grey cement hinges on aesthetic demands and functional requirements, balancing appearance with performance.

Composition Differences

White cement contains higher amounts of raw materials such as kaolin and bauxite, resulting in its characteristic white color, while grey cement includes iron oxides and manganese that give it a darker hue. The clinker for white cement is fired at lower temperatures to reduce the formation of colored compounds, whereas grey cement's process allows for higher iron oxide content contributing to its color and strength. These composition differences influence not only the aesthetic finish but also the application specificity and cost of each type of cement.

Manufacturing Process Comparison

White cement is manufactured using raw materials with low iron and manganese content, such as kaolin and chalk, which ensures its bright white color, while grey cement uses iron-rich materials like limestone and clay that result in its typical grey hue. The kiln temperature and cooling process for white cement are carefully controlled to prevent color defects, unlike grey cement, which allows for higher temperature variations. The grinding process of white cement also requires separate equipment to avoid contamination by iron, ensuring the final product retains its whiteness and strength.

Color and Appearance

White cement offers a bright, clean color that enhances architectural aesthetics and allows for vibrant finishes, while grey cement has a traditional, darker hue that can mask imperfections. The pure white color results from raw materials low in iron and manganese, providing a smooth, uniform appearance ideal for decorative purposes. Your choice between white and grey cement will significantly impact the visual outcome of your masonry or concrete project.

Strength and Durability

White cement typically exhibits comparable compressive strength to grey cement, often ranging between 30 to 50 MPa depending on mix design and curing conditions. Its durability is enhanced by low iron content, which reduces the risk of staining and corrosion in architectural applications. Grey cement is renowned for its robust strength performance and versatile durability in structural uses, making it suitable for heavy-duty construction projects.

Applications and Uses

White cement is commonly used for architectural and decorative purposes due to its bright, clean appearance, making it ideal for facades, tiles, and terrazzo flooring. Grey cement is preferred for structural applications such as foundations, bridges, and general construction because of its strength and durability. Your choice between white and grey cement depends on whether aesthetics or structural requirements are the priority.

Cost and Price Factors

White cement typically costs 30-50% more than grey cement due to the higher purity of raw materials and specialized manufacturing processes required to achieve its bright color. The price factors for white cement also include limited production sites, increased energy consumption, and added processing steps, which result in higher market prices. Grey cement remains the more economical choice for most construction projects due to its widespread availability and simpler production methods.

Environmental Impact

White cement production typically has a higher environmental impact compared to grey cement due to the extensive use of raw materials like kaolin and the additional energy-intensive processes required for bleaching and sintering. Grey cement, primarily made from limestone and clay, tends to have lower carbon emissions during manufacturing, making it a more eco-friendly option in construction projects. Reducing clinker content and incorporating supplementary cementitious materials in both types can significantly mitigate their overall environmental footprint.

Workability and Finishing

White cement offers superior workability and smooth finishing due to its fine particle size and uniform color, making it ideal for decorative and architectural applications. Grey cement, while strong and durable, typically results in a coarser texture and less polished finish, suitable for structural projects rather than aesthetic-focused work. The enhanced brightness and consistent surface of white cement facilitate easier polishing and painting compared to grey cement.

Choosing the Right Cement for Your Project

White cement offers superior aesthetic appeal with its bright color, making it ideal for decorative finishes, architectural designs, and precast applications, while grey cement is more commonly used for structural purposes due to its strength and cost-effectiveness. Your project requirements, such as color preference, durability, and budget, will determine the optimal choice between white and grey cement. Understanding the chemical composition and performance characteristics of each type ensures you select the right cement for durability and visual impact.

White cement vs Grey cement Infographic

libmatt.com

libmatt.com