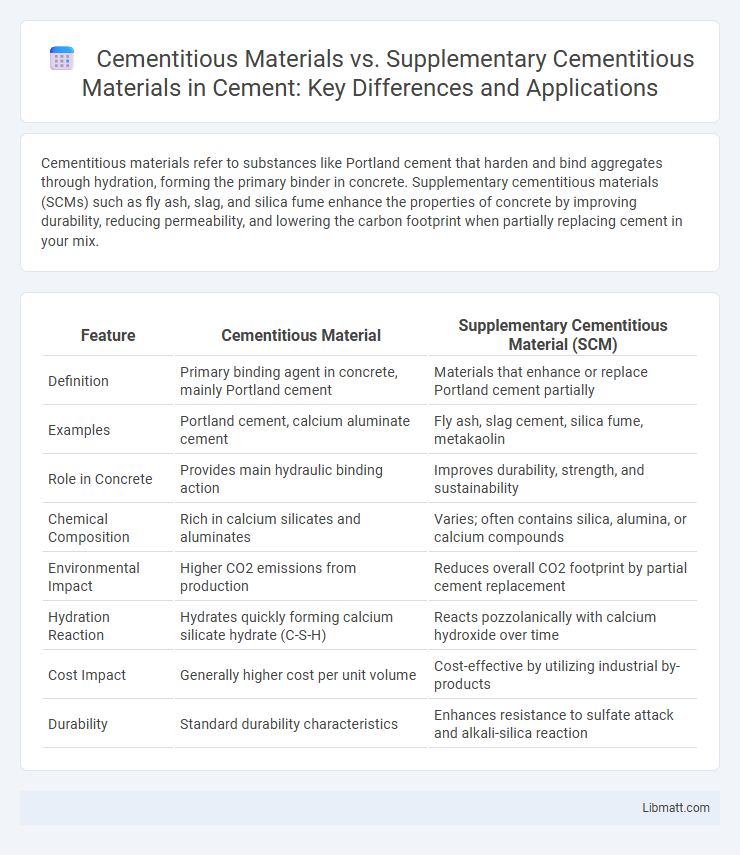

Cementitious materials refer to substances like Portland cement that harden and bind aggregates through hydration, forming the primary binder in concrete. Supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume enhance the properties of concrete by improving durability, reducing permeability, and lowering the carbon footprint when partially replacing cement in your mix.

Table of Comparison

| Feature | Cementitious Material | Supplementary Cementitious Material (SCM) |

|---|---|---|

| Definition | Primary binding agent in concrete, mainly Portland cement | Materials that enhance or replace Portland cement partially |

| Examples | Portland cement, calcium aluminate cement | Fly ash, slag cement, silica fume, metakaolin |

| Role in Concrete | Provides main hydraulic binding action | Improves durability, strength, and sustainability |

| Chemical Composition | Rich in calcium silicates and aluminates | Varies; often contains silica, alumina, or calcium compounds |

| Environmental Impact | Higher CO2 emissions from production | Reduces overall CO2 footprint by partial cement replacement |

| Hydration Reaction | Hydrates quickly forming calcium silicate hydrate (C-S-H) | Reacts pozzolanically with calcium hydroxide over time |

| Cost Impact | Generally higher cost per unit volume | Cost-effective by utilizing industrial by-products |

| Durability | Standard durability characteristics | Enhances resistance to sulfate attack and alkali-silica reaction |

Introduction to Cementitious Materials

Cementitious materials are substances that possess the ability to harden and bind aggregate particles together when mixed with water, primarily including Portland cement. Supplementary cementitious materials (SCMs) such as fly ash, slag cement, and silica fume are by-products used to partially replace Portland cement, enhancing concrete durability, strength, and sustainability. These SCMs contribute to reduced carbon footprint and improved long-term performance in concrete applications by participating in pozzolanic or hydraulic reactions.

Defining Supplementary Cementitious Materials (SCMs)

Supplementary Cementitious Materials (SCMs) are finely divided mineral materials that, when used in conjunction with Portland cement, enhance the durability, strength, and sustainability of concrete. Materials such as fly ash, slag cement, silica fume, and natural pozzolans replace a portion of cement to reduce carbon emissions and improve long-term performance. Your concrete mixes benefit from SCMs by achieving improved workability, reduced permeability, and increased resistance to chemical attacks.

Key Differences Between Cementitious and Supplementary Cementitious Materials

Cementitious materials primarily include Portland cement and other compounds that hydrate and gain strength independently, forming the basis of concrete. Supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume, are inert or have minimal hydraulic properties but react chemically with calcium hydroxide released during cement hydration to enhance durability and reduce permeability. Understanding these key differences helps you optimize concrete mixtures for improved performance, sustainability, and cost-effectiveness.

Common Types of Cementitious Materials

Common types of cementitious materials include Portland cement, which is the primary binder in concrete and mortar. Supplementary cementitious materials (SCMs) such as fly ash, slag cement, and silica fume enhance concrete properties by improving durability, strength, and sustainability. Understanding these materials helps you select the right combination for optimized construction performance.

Popular Forms of Supplementary Cementitious Materials

Supplementary Cementitious Materials (SCMs) include popular forms such as fly ash, silica fume, slag cement, and natural pozzolans, which enhance concrete durability and reduce environmental impact. Fly ash, a byproduct of coal combustion, improves workability and reduces permeability, while silica fume, a byproduct of silicon and ferrosilicon alloy production, increases strength and resistance to chemical attack. Your concrete mixes benefit significantly from the optimized selection of these SCMs, offering improved performance over traditional cementitious materials alone.

Chemical and Physical Properties Comparison

Cementitious materials primarily consist of Portland cement, characterized by their hydraulic properties due to compounds like tricalcium silicate and dicalcium silicate, which react with water to form calcium silicate hydrate providing strength. Supplementary cementitious materials (SCMs) such as fly ash, silica fume, and slag exhibit pozzolanic or latent hydraulic properties, contributing to strength and durability through secondary reactions with calcium hydroxide. Physically, SCMs often have finer particle sizes and greater surface areas compared to conventional cement, enhancing packing density and reducing permeability in concrete mixtures.

Role in Concrete Mix Design

Cementitious materials, such as Portland cement, primarily react with water to form the binder that sets and hardens concrete, providing strength and durability. Supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume enhance concrete mix design by improving workability, reducing permeability, and increasing long-term strength through pozzolanic or latent hydraulic reactions. Incorporating SCMs in concrete mix design optimizes performance, sustainability, and cost-effectiveness while minimizing the environmental impact of cement production.

Environmental Impacts and Sustainability

Cementitious materials, primarily Portland cement, exhibit high carbon emissions due to energy-intensive calcination and fossil fuel use, contributing significantly to global CO2 levels. Supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume reduce environmental impact by recycling industrial by-products, lowering clinker content, and enhancing sustainability in concrete production. Your choice to incorporate SCMs promotes resource efficiency, reduces landfill waste, and helps achieve greener, more sustainable construction practices.

Performance and Durability Benefits

Cementitious materials, such as ordinary Portland cement, provide foundational strength and setting properties in concrete, while supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume enhance performance by improving workability, reducing permeability, and increasing resistance to chemical attacks. SCMs contribute to durability by refining pore structure, mitigating alkali-silica reaction, and improving long-term strength development, resulting in extended service life of concrete structures. The integration of SCMs in concrete mixtures leads to sustainable construction with superior mechanical properties and increased resilience against environmental degradation.

Practical Applications and Industry Trends

Cementitious materials, primarily Portland cement, serve as the binder in concrete production, crucial for structural strength in construction projects such as bridges, buildings, and roads. Supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume enhance durability, reduce carbon footprint, and improve workability, aligning with industry trends toward sustainability and cost-effectiveness. Your choice between these materials influences environmental impact and long-term performance, reflecting a growing shift in the construction industry toward SCMs for green building practices and regulatory compliance.

Cementitious Material vs Supplementary Cementitious Material Infographic

libmatt.com

libmatt.com