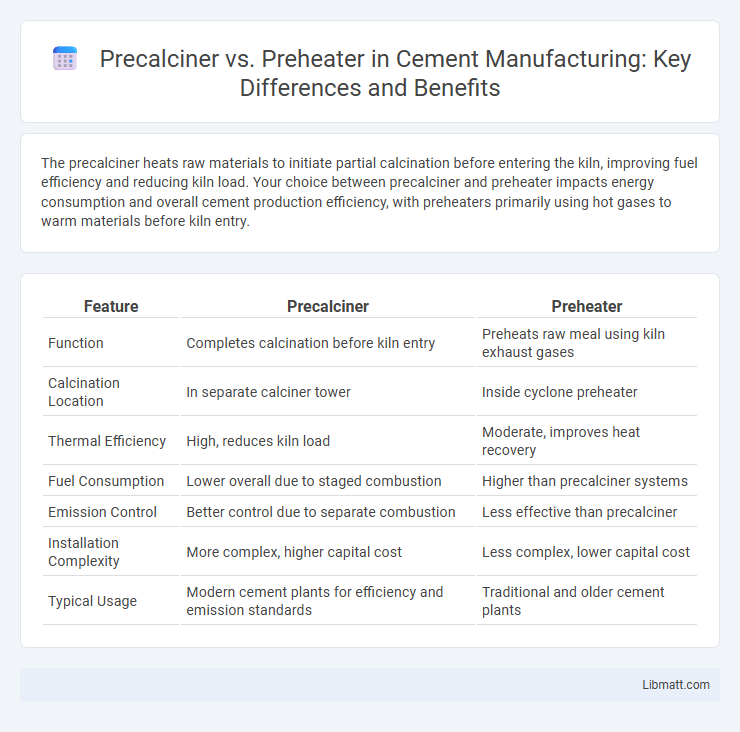

The precalciner heats raw materials to initiate partial calcination before entering the kiln, improving fuel efficiency and reducing kiln load. Your choice between precalciner and preheater impacts energy consumption and overall cement production efficiency, with preheaters primarily using hot gases to warm materials before kiln entry.

Table of Comparison

| Feature | Precalciner | Preheater |

|---|---|---|

| Function | Completes calcination before kiln entry | Preheats raw meal using kiln exhaust gases |

| Calcination Location | In separate calciner tower | Inside cyclone preheater |

| Thermal Efficiency | High, reduces kiln load | Moderate, improves heat recovery |

| Fuel Consumption | Lower overall due to staged combustion | Higher than precalciner systems |

| Emission Control | Better control due to separate combustion | Less effective than precalciner |

| Installation Complexity | More complex, higher capital cost | Less complex, lower capital cost |

| Typical Usage | Modern cement plants for efficiency and emission standards | Traditional and older cement plants |

Introduction to Precalciner and Preheater Systems

Precalciner and preheater systems are essential components in cement production, enhancing energy efficiency and reducing fuel consumption. A precalciner is a combustion chamber where a significant portion of the raw meal is calcined before entering the kiln, enabling higher production capacity and improved thermal efficiency. Preheaters, typically tower-like structures with cyclones, use hot kiln gases to preheat raw materials, boosting kiln performance by minimizing fuel usage and increasing throughput.

Key Differences Between Precalciner and Preheater

The key differences between a precalciner and a preheater in cement production lie in their functions and positions within the kiln system. A preheater heats raw materials using hot gases before entering the kiln, enhancing thermal efficiency, while a precalciner is a combustion chamber that partially calcines the raw meal, increasing the degree of chemical reaction prior to the kiln's main firing zone. Understanding these distinctions helps optimize your cement manufacturing process by improving fuel efficiency and clinker quality.

Working Principle of Preheater

The working principle of a preheater involves utilizing hot gases from the kiln to raise the temperature of raw materials before they enter the kiln, improving thermal efficiency. This process uses multiple cyclone stages where raw meal and hot gases exchange heat, ensuring the raw material dries and partially reacts before kiln entry. Preheaters reduce fuel consumption, enhance clinker quality, and increase overall kiln productivity compared to traditional precalciner systems.

Working Principle of Precalciner

The working principle of a precalciner involves partially calcining raw meal before it enters the rotary kiln, enhancing fuel efficiency and increasing production capacity in cement manufacturing. This process uses a separate combustion chamber where fuel and air are burned to heat the raw material, facilitating the decomposition of calcium carbonate into lime and carbon dioxide. In contrast, a preheater primarily functions to preheat the raw meal using hot gases from the kiln, without significant chemical change prior to kiln entry.

Advantages of Precalciner Technology

Precalciner technology offers enhanced fuel efficiency by enabling a higher degree of clinker calcination before entering the kiln, significantly reducing fuel consumption and CO2 emissions. Its design allows for greater operational flexibility and higher production capacity with improved temperature control and uniform clinker quality. You benefit from lower maintenance costs and increased kiln throughput due to the decoupling of the calcination process from the rotary kiln.

Advantages of Preheater Systems

Preheater systems improve energy efficiency by utilizing hot gases from the kiln to preheat raw materials, reducing fuel consumption and lowering emissions. They offer better temperature control and quicker start-up times compared to precalciner systems. Your cement production process benefits from increased throughput and reduced operational costs with preheater technology.

Energy Efficiency Comparison

Precalciners achieve higher energy efficiency by enabling more complete combustion of fuel before the material enters the kiln, resulting in lower fuel consumption and reduced CO2 emissions. Preheaters improve thermal efficiency by utilizing waste kiln gases to heat raw material, but they typically consume more fuel compared to precalciner systems. Industrial studies show precalciner kilns can reduce fuel use by up to 30% compared to traditional preheater kilns, making precalciner technology the preferred solution for energy-efficient cement production.

Impact on Cement Production Quality

Precalciner and preheater technologies significantly influence cement production quality by enhancing clinker formation and fuel efficiency. Precalciners improve combustion control and allow for higher feed rates, leading to more consistent clinker quality and reduced emissions. Your cement products benefit from the optimized chemical composition and particle size distribution achieved through advanced precalciner systems.

Environmental Considerations

Precalciners and preheaters significantly impact environmental performance in cement production by reducing CO2 emissions through improved fuel efficiency and lower energy consumption. Precalciners enable higher combustion rates and more complete fuel burn, resulting in decreased greenhouse gas output compared to traditional preheater systems. Incorporating advanced precalciner technology often leads to better control of particulate emissions and reduces the reliance on fossil fuels by facilitating alternative fuel usage.

Choosing the Right System for Your Cement Plant

Selecting the appropriate system between a precalciner and a preheater depends on factors like plant capacity, fuel efficiency, and emissions control. A precalciner system provides higher thermal efficiency by allowing up to 70% of the limestone to be calcined before entering the kiln, reducing fuel consumption and increasing production rates. Conversely, a preheater system is simpler with lower initial costs but may result in higher fuel usage and lower throughput, making it suitable for smaller or less complex cement plants.

Precalciner vs Preheater Infographic

libmatt.com

libmatt.com