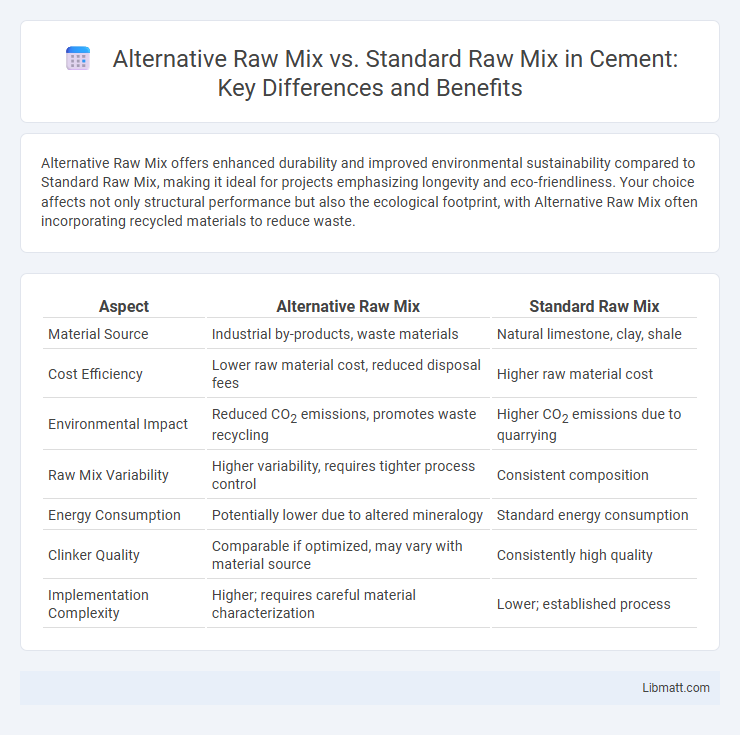

Alternative Raw Mix offers enhanced durability and improved environmental sustainability compared to Standard Raw Mix, making it ideal for projects emphasizing longevity and eco-friendliness. Your choice affects not only structural performance but also the ecological footprint, with Alternative Raw Mix often incorporating recycled materials to reduce waste.

Table of Comparison

| Aspect | Alternative Raw Mix | Standard Raw Mix |

|---|---|---|

| Material Source | Industrial by-products, waste materials | Natural limestone, clay, shale |

| Cost Efficiency | Lower raw material cost, reduced disposal fees | Higher raw material cost |

| Environmental Impact | Reduced CO2 emissions, promotes waste recycling | Higher CO2 emissions due to quarrying |

| Raw Mix Variability | Higher variability, requires tighter process control | Consistent composition |

| Energy Consumption | Potentially lower due to altered mineralogy | Standard energy consumption |

| Clinker Quality | Comparable if optimized, may vary with material source | Consistently high quality |

| Implementation Complexity | Higher; requires careful material characterization | Lower; established process |

Introduction to Raw Mixes in Cement Production

Raw mixes in cement production consist of carefully blended limestone, clay, and other materials, which serve as the foundational components for clinker formation. The alternative raw mix incorporates industrial by-products or non-traditional materials like slag or fly ash, reducing reliance on virgin resources and lowering carbon emissions. Standard raw mix typically relies on conventional natural materials, offering consistent chemical composition but often with higher environmental impact.

Defining Standard Raw Mix: Composition and Characteristics

Standard Raw Mix primarily consists of limestone, clay, and sand in precise proportions to achieve optimal chemical balance for clinker production in cement manufacturing. Its composition typically maintains a lime saturation factor (LSF) between 0.92 and 1.02, ensuring consistent burnability and clinker quality. Understanding the specific characteristics of your standard raw mix is essential for controlling kiln operations and maintaining cement performance standards.

Understanding Alternative Raw Mixes: Innovation and Variability

Alternative raw mixes offer innovation by incorporating diverse materials such as industrial by-products and recycled components, leading to enhanced sustainability and cost efficiency in cement production. These mixes introduce variability in chemical composition, requiring careful adjustment of kiln parameters to maintain product quality and performance. Understanding the balance between raw material characteristics and process control is crucial for optimizing the benefits of alternative raw mixes compared to standard raw mixes.

Key Differences Between Standard and Alternative Raw Mixes

Standard raw mixes primarily consist of traditional materials like limestone, clay, and sand, offering a consistent chemical composition crucial for cement production. Alternative raw mixes incorporate industrial by-products such as slag, fly ash, or recycled materials, aiming to reduce environmental impact and raw material costs. The key differences lie in their source materials, environmental footprint, and potential effects on kiln stability and clinker quality.

Raw Material Sources for Alternative vs Standard Mixes

Alternative raw mixes utilize a diverse range of raw material sources, including industrial by-products like fly ash, slag, or recycled materials, reducing reliance on virgin limestone and clay typical in standard raw mixes. These alternative sources contribute to sustainability by lowering carbon emissions and conserving natural resources while maintaining the chemical composition needed for cement production. Your choice between standard and alternative raw mixes impacts environmental footprint and raw material availability, influencing production efficiency and regulatory compliance.

Environmental Impact: Sustainability Considerations

Alternative Raw Mix significantly reduces environmental impact by incorporating industrial by-products such as slag and fly ash, lowering the demand for natural raw materials and minimizing CO2 emissions during production. Standard Raw Mix relies heavily on virgin limestone and clay extraction, leading to higher energy consumption and greater ecological disturbance. Your choice of Alternative Raw Mix supports sustainability efforts by promoting resource efficiency and reducing the carbon footprint of cement manufacturing.

Cost Implications of Alternative vs Standard Raw Mix

Alternative raw mix offers significant cost savings compared to the standard raw mix by utilizing locally available or recycled materials, reducing transportation and material expenses. Standard raw mix typically involves higher costs due to reliance on more consistent but often pricier virgin raw materials and stricter quality control measures. You can optimize your production budget effectively by evaluating the cost-benefit trade-offs between alternative and standard raw mix compositions.

Performance and Quality Outcomes

Alternative raw mix formulations enhance kiln performance by improving fuel efficiency and reducing emissions compared to standard raw mixes. Your cement production benefits from more consistent clinker quality and lower operational costs due to optimized chemical compositions and better thermal behavior. These performance gains translate into higher-quality cement with improved strength development and durability.

Challenges in Implementing Alternative Raw Mixes

Implementing alternative raw mixes in cement production faces challenges like inconsistent material quality, which affects clinker properties and overall product strength. Variability in alternative raw materials requires precise process adjustments and advanced monitoring systems to maintain cement specifications. Ensuring supply chain stability for these unconventional sources also presents logistical and economic difficulties.

Future Trends in Raw Mix Selection

Future trends in raw mix selection emphasize the integration of alternative raw mix materials such as industrial byproducts and recycled components to reduce carbon footprint and raw material consumption. Advances in sensor technology and AI-driven process optimization enable real-time adjustments to raw mix composition, enhancing cement quality and energy efficiency. Sustainability regulations and circular economy principles drive increased adoption of alternative raw mixes, promoting environmental compliance and cost-effective production.

Alternative Raw Mix vs Standard Raw Mix Infographic

libmatt.com

libmatt.com