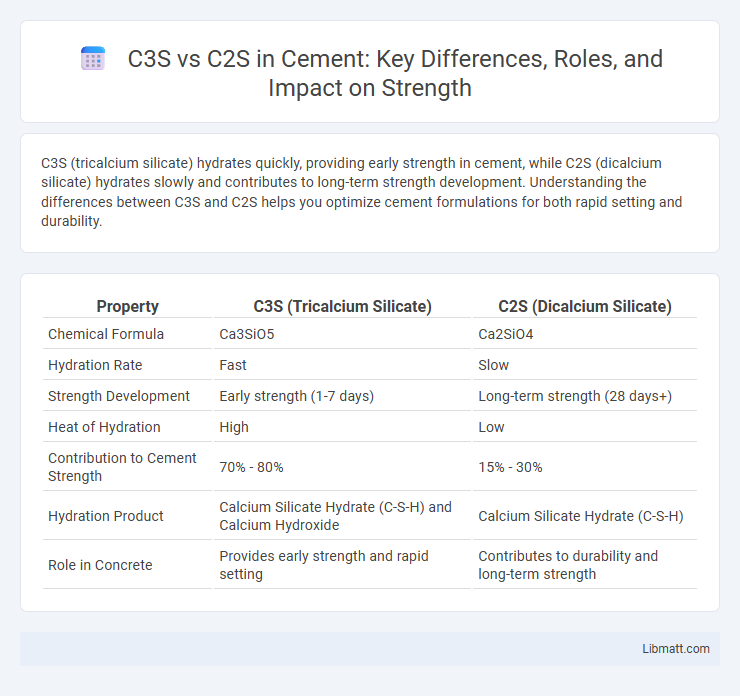

C3S (tricalcium silicate) hydrates quickly, providing early strength in cement, while C2S (dicalcium silicate) hydrates slowly and contributes to long-term strength development. Understanding the differences between C3S and C2S helps you optimize cement formulations for both rapid setting and durability.

Table of Comparison

| Property | C3S (Tricalcium Silicate) | C2S (Dicalcium Silicate) |

|---|---|---|

| Chemical Formula | Ca3SiO5 | Ca2SiO4 |

| Hydration Rate | Fast | Slow |

| Strength Development | Early strength (1-7 days) | Long-term strength (28 days+) |

| Heat of Hydration | High | Low |

| Contribution to Cement Strength | 70% - 80% | 15% - 30% |

| Hydration Product | Calcium Silicate Hydrate (C-S-H) and Calcium Hydroxide | Calcium Silicate Hydrate (C-S-H) |

| Role in Concrete | Provides early strength and rapid setting | Contributes to durability and long-term strength |

Introduction to C3S and C2S

C3S (Tricalcium Silicate) and C2S (Dicalcium Silicate) are essential compounds in Portland cement that influence the material's strength and setting time. C3S primarily contributes to early strength development within the first 7 days, while C2S contributes to long-term strength gain over several months. Understanding the balance between C3S and C2S is crucial for optimizing Your concrete mix for specific construction needs.

Chemical Composition Differences

C3S (tricalcium silicate) and C2S (dicalcium silicate) differ primarily in their calcium-to-silicon ratio, with C3S containing approximately 3CaO*SiO2 and C2S 2CaO*SiO2. C3S has a higher calcium oxide content, contributing to its faster hydration rate and greater early strength development compared to C2S. The variations in chemical composition influence their roles in cement hydration, where C3S hydrates rapidly producing calcium silicate hydrate and calcium hydroxide, while C2S hydrates more slowly, contributing to long-term strength.

Role in Cement Hydration

C3S (Tricalcium Silicate) plays a crucial role in early cement hydration by rapidly reacting with water to form calcium silicate hydrate (C-S-H) and calcium hydroxide, providing early strength development within the first 7 days. In contrast, C2S (Dicalcium Silicate) hydrates more slowly, contributing to strength gain primarily during the later stages of curing, typically beyond 7 days. The combination of C3S and C2S ensures both early and long-term strength in concrete, optimizing overall durability and performance.

Physical Properties Comparison

C3S (tricalcium silicate) exhibits faster hydration rates and higher early strength development compared to C2S (dicalcium silicate), making it crucial for early setting in cement. C2S hydrates more slowly, contributing to strength gains primarily at later stages, enhancing long-term durability. Both phases differ significantly in heat evolution, with C3S generating more heat during hydration than C2S, influencing thermal properties of cementitious materials.

Impact on Setting Time

C3S (Tricalcium Silicate) significantly accelerates the setting time of cement, contributing to early strength development within the first 7 days. In contrast, C2S (Dicalcium Silicate) hydrates more slowly, resulting in a prolonged setting time but providing strength gain over a longer period, typically beyond 7 days. The proportion of C3S to C2S in cement directly influences both initial and final setting times, affecting concrete workability and construction scheduling.

Influence on Strength Development

C3S (Tricalcium Silicate) significantly accelerates early strength development in cement, contributing to rapid hydration and strength gain within the first 7 days. C2S (Dicalcium Silicate) hydrates at a slower rate, providing sustained strength increase over the long term, typically after 28 days and beyond. The balanced proportion of C3S and C2S in clinker influences both the initial setting time and the ultimate durability of concrete structures.

Heat Generation and Thermal Effects

C3S (tricalcium silicate) generates significant heat during hydration, contributing to rapid strength gain due to its exothermic reaction with water. In contrast, C2S (dicalcium silicate) produces much less heat, resulting in slower strength development and lower thermal stress within concrete structures. The reduced heat generation from C2S minimizes the risk of thermal cracking, making it preferable for large-scale pours and mass concrete applications.

Durability and Long-term Performance

C3S (Tricalcium Silicate) and C2S (Dicalcium Silicate) differ significantly in durability and long-term performance. C3S contributes to rapid strength development and early durability but may be more prone to shrinkage and cracking over time. In contrast, C2S hydrates slowly, providing enhanced long-term strength and better resistance to chemical attack, resulting in improved durability for structures exposed to aggressive environments.

Practical Applications in Construction

C3S (alite) contributes to rapid strength development and early setting in concrete, making it ideal for projects requiring quick formwork removal and early load bearing, such as precast elements and fast-track construction. C2S (belite) hydrates more slowly, providing long-term strength and durability, suitable for massive structures like dams and bridges where extended curing is beneficial. Balancing C3S and C2S content optimizes concrete mix designs to achieve both initial strength and long-term performance.

Summary Table: C3S vs C2S

C3S (Tricalcium Silicate) and C2S (Dicalcium Silicate) are key compounds in Portland cement, with C3S contributing to early strength development and C2S providing long-term strength. A summary table comparing C3S and C2S highlights differences such as hydration rate, heat evolution, and impact on concrete durability. Your choice between C3S and C2S influences cement performance, shaping construction outcomes like setting time and structural integrity.

C3S vs C2S Infographic

libmatt.com

libmatt.com