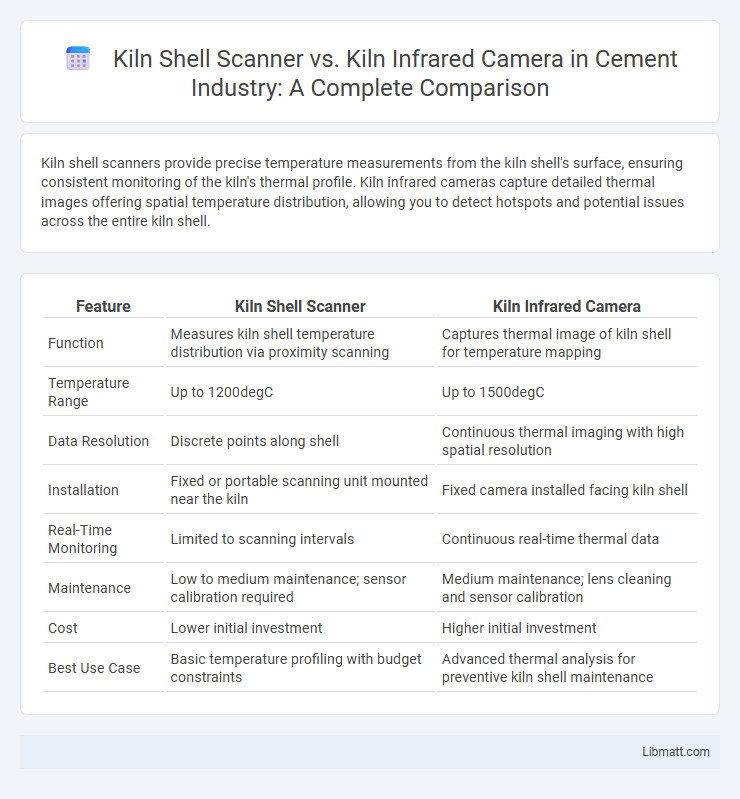

Kiln shell scanners provide precise temperature measurements from the kiln shell's surface, ensuring consistent monitoring of the kiln's thermal profile. Kiln infrared cameras capture detailed thermal images offering spatial temperature distribution, allowing you to detect hotspots and potential issues across the entire kiln shell.

Table of Comparison

| Feature | Kiln Shell Scanner | Kiln Infrared Camera |

|---|---|---|

| Function | Measures kiln shell temperature distribution via proximity scanning | Captures thermal image of kiln shell for temperature mapping |

| Temperature Range | Up to 1200degC | Up to 1500degC |

| Data Resolution | Discrete points along shell | Continuous thermal imaging with high spatial resolution |

| Installation | Fixed or portable scanning unit mounted near the kiln | Fixed camera installed facing kiln shell |

| Real-Time Monitoring | Limited to scanning intervals | Continuous real-time thermal data |

| Maintenance | Low to medium maintenance; sensor calibration required | Medium maintenance; lens cleaning and sensor calibration |

| Cost | Lower initial investment | Higher initial investment |

| Best Use Case | Basic temperature profiling with budget constraints | Advanced thermal analysis for preventive kiln shell maintenance |

Introduction to Kiln Shell Monitoring

Kiln shell monitoring involves tracking temperature variations on the external surface of rotary kilns to prevent structural damage and optimize performance. Kiln shell scanners provide continuous, high-resolution temperature profiles by scanning the shell circumference, while kiln infrared cameras capture real-time thermal images for detailed hotspot analysis. Your choice depends on the need for comprehensive temperature mapping versus focused thermal visualization to maintain kiln safety and efficiency.

Overview of Kiln Shell Scanners

Kiln shell scanners are specialized devices designed to measure the surface temperature of rotary kiln shells accurately, using contact or non-contact methods that provide critical data for maintaining kiln integrity and efficiency. Unlike kiln infrared cameras, which capture thermal images for broader heat distribution analysis, shell scanners focus on pinpoint temperature readings along the kiln's rotating surface to detect hotspots or structural weaknesses. These scanners enable proactive maintenance by monitoring temperature gradients, preventing shell deformation, and optimizing kiln performance in cement and refractory industries.

Overview of Kiln Infrared Cameras

Kiln infrared cameras provide precise thermal imaging to monitor temperature distribution across the kiln shell, ensuring efficient and uniform heating while preventing overheating or cold spots. Unlike kiln shell scanners that primarily detect surface abnormalities, infrared cameras capture real-time temperature data, allowing you to optimize firing conditions and maintain kiln integrity effectively. These cameras enhance predictive maintenance, reduce energy consumption, and improve product quality through accurate thermal profiling.

Key Functional Differences

Kiln shell scanners use laser or ultrasound technology to detect shell surface defects and thickness variations with high precision, while kiln infrared cameras capture thermal images to monitor temperature distribution and heat patterns across the shell. These differences enable the shell scanner to provide detailed structural assessment, whereas the infrared camera focuses on thermal analysis critical for optimizing kiln operation. Understanding these key functional differences helps you choose the right tool for either mechanical inspection or thermal management in kiln maintenance.

Accuracy and Sensitivity Comparison

Kiln shell scanners provide precise temperature measurements by detecting the exact shell surface temperature, ensuring high accuracy for monitoring kiln operation. Kiln infrared cameras offer broader thermal imaging with enhanced sensitivity, capturing detailed heat distribution patterns that can reveal subtle hot spots or cold zones along the kiln shell. Your choice between these tools depends on whether you prioritize pinpoint accuracy or comprehensive thermal sensitivity for effective kiln maintenance.

Installation and Maintenance Considerations

Kiln shell scanners offer straightforward installation with minimal structural modifications, making them ideal for quick deployment and easier access during maintenance. Kiln infrared cameras require precise positioning and protective housings due to sensitivity to environmental conditions, increasing installation complexity and ongoing maintenance needs. Both technologies demand regular calibration, but shell scanners typically involve less downtime and simpler cleaning procedures, enhancing operational efficiency.

Data Visualization and Reporting Features

Kiln shell scanners provide precise temperature mapping with detailed 2D visuals, enabling you to pinpoint hot and cold zones for focused troubleshooting. Kiln infrared cameras deliver real-time thermal imaging with dynamic color palettes and video recordings, facilitating comprehensive monitoring and immediate decision-making. Both tools offer advanced reporting capabilities, but infrared cameras typically support more interactive data analysis and customizable reports for in-depth thermal performance assessment.

Cost and Return on Investment

Kiln shell scanners typically have lower upfront costs compared to kiln infrared cameras, making them a more budget-friendly option for continuous temperature monitoring. Infrared cameras, while more expensive initially, provide more detailed thermal imaging that can lead to earlier detection of issues and reduced downtime, potentially increasing return on investment through preventive maintenance. Investing in an infrared camera often yields higher long-term savings due to improved energy efficiency and extended kiln lifespan.

Application Scenarios: When to Use Each Technology

Kiln shell scanners are ideal for detecting shell thickness variations and identifying potential weak spots during continuous kiln operation, especially in heavy industrial settings like cement or lime production. Kiln infrared cameras excel in monitoring temperature distribution across the kiln shell, crucial for preventing overheating and optimizing thermal efficiency in both rotary and tunnel kilns. Your choice depends on whether precise shell integrity assessment or detailed thermal profiling is the priority for maintenance and process control.

Future Trends in Kiln Temperature Monitoring

Kiln shell scanners and kiln infrared cameras represent key technologies in the future of kiln temperature monitoring, with infrared cameras providing real-time thermal imaging for precise heat distribution analysis. These advancements enable predictive maintenance and energy efficiency improvements by detecting hotspots and temperature fluctuations early. You can leverage these tools to optimize kiln operations, reduce downtime, and enhance product quality through more accurate and continuous temperature monitoring.

Kiln shell scanner vs Kiln infrared camera Infographic

libmatt.com

libmatt.com