Low heat cement generates less heat during hydration, reducing the risk of thermal cracking in large concrete structures, while sulphate resisting cement is specially formulated to withstand sulfate attacks in aggressive environments, protecting concrete from chemical deterioration. You should choose low heat cement for massive pours and sulphate resisting cement in soils or waters with high sulfate content to ensure durability.

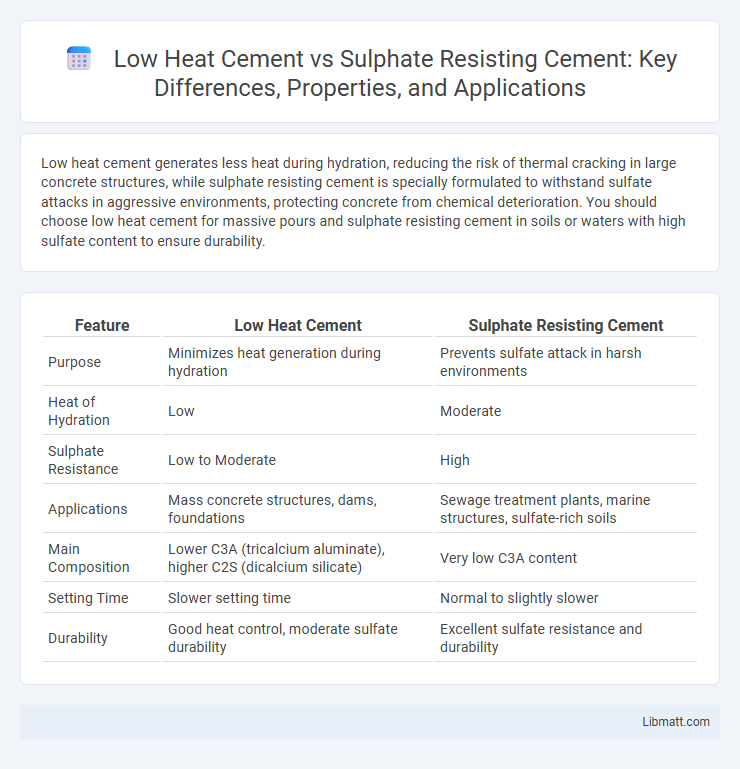

Table of Comparison

| Feature | Low Heat Cement | Sulphate Resisting Cement |

|---|---|---|

| Purpose | Minimizes heat generation during hydration | Prevents sulfate attack in harsh environments |

| Heat of Hydration | Low | Moderate |

| Sulphate Resistance | Low to Moderate | High |

| Applications | Mass concrete structures, dams, foundations | Sewage treatment plants, marine structures, sulfate-rich soils |

| Main Composition | Lower C3A (tricalcium aluminate), higher C2S (dicalcium silicate) | Very low C3A content |

| Setting Time | Slower setting time | Normal to slightly slower |

| Durability | Good heat control, moderate sulfate durability | Excellent sulfate resistance and durability |

Introduction to Low Heat Cement and Sulphate Resisting Cement

Low Heat Cement is designed to release heat slowly during hydration, minimizing thermal cracking in massive concrete structures such as dams and large foundations. Sulphate Resisting Cement contains a low amount of tricalcium aluminate, enhancing its durability against sulfate attacks in environments with high sulfate concentrations like marine or sewage-exposed soils. Both cements are specialized types of Portland cement tailored for specific structural and environmental challenges.

Chemical Composition Differences

Low heat cement contains a higher proportion of belite (C2S) and a reduced amount of alite (C3S), which slows the hydration process and minimizes heat generation. Sulphate resisting cement is formulated with a low amount of tricalcium aluminate (C3A) to enhance resistance against sulfate attack and prevent chemical degradation. Your choice depends on whether controlling hydration heat or improving sulfate resistance is the primary concern in your construction project.

Manufacturing Process Comparison

Low heat cement is produced by adjusting the proportions of clinker minerals, specifically reducing tricalcium aluminate (C3A) and tricalcium silicate (C3S) content, to minimize heat generation during hydration. Sulphate resisting cement undergoes a similar approach but emphasizes increasing the percentage of belite (C2S) and reducing C3A to enhance resistance against sulphate attack, with stricter control on kiln temperature and raw material composition. The manufacturing process for both cements involves precise selection and grinding of raw materials, but sulphate resisting cement requires more stringent kiln operation and quality control to ensure its durability in aggressive environments.

Key Physical Properties

Low heat cement exhibits a lower heat of hydration, reducing thermal cracking in massive concrete structures, with moderate strength development and density comparable to ordinary Portland cement. Sulphate resisting cement offers enhanced chemical durability against sulfate attack, characterized by lower permeability and higher resistance to expansion and cracking in sulfate-rich environments. Both cements have similar setting times but differ significantly in their chemical composition, affecting long-term durability and application suitability.

Heat of Hydration: Low Heat Cement vs Sulphate Resisting Cement

Low heat cement generates significantly less heat of hydration compared to sulphate resisting cement, making it ideal for large concrete pours to reduce thermal cracking risks. Sulphate resisting cement produces higher heat due to its composition but offers enhanced durability in sulfate-rich environments, preventing concrete deterioration. Understanding the heat of hydration differences is crucial for selecting the right cement type based on structural and environmental demands.

Resistance to Sulfate Attack

Low heat cement exhibits moderate sulfate resistance, making it suitable for large concrete structures where heat generation control is essential, but it may not withstand highly aggressive sulfate environments. Sulfate resisting cement (SRC) contains a low C3A content, providing superior resistance to sulfate attack, especially in soils or waters with high sulfate concentrations. For projects exposed to harsh sulfate conditions, choosing sulfate resisting cement ensures better durability and longevity of your concrete structures.

Applications in Construction

Low heat cement is ideal for massive concrete structures such as dams and large foundations where minimizing thermal cracking is critical due to its slow hydration process and reduced heat generation. Sulphate resisting cement is specifically designed for construction in environments exposed to high sulfate concentrations, such as sewage treatment plants, coastal structures, and foundations in sulfate-rich soils, preventing sulfate-induced deterioration. Your choice between these cements depends on the environmental conditions and structural requirements to ensure durability and longevity of the construction.

Advantages and Disadvantages

Low heat cement offers the advantage of reducing temperature rise during hydration, minimizing thermal cracking in mass concrete structures, but it typically has slower strength development compared to ordinary cement. Sulphate resisting cement is specifically designed to withstand aggressive sulphate environments, protecting Your concrete from chemical attack and deterioration, though it may come at a higher cost and reduced early strength. Choosing between the two depends on the specific environmental conditions and structural requirements of Your project.

Standards and Specifications

Low heat cement is governed by standards such as ASTM C150 Type IV and EN 197-1 CEM III/A, which specify its use in massive concrete structures to limit heat generation during hydration. Sulphate resisting cement adheres to ASTM C150 Type V and IS 12330 standards, designed specifically to withstand aggressive sulphate environments by reducing tricalcium aluminate content. Both cements have strict compositional requirements and performance criteria to ensure durability and structural integrity under specific environmental conditions.

Selection Criteria for Various Projects

Low heat cement is ideal for massive concrete structures like dams and large foundations where controlling heat of hydration minimizes thermal cracking risks. Sulphate resisting cement suits environments exposed to aggressive sulfate soils or groundwater in sewage treatment plants and marine structures due to its enhanced chemical durability. Selection depends on exposure conditions and structural scale, prioritizing thermal management for large volumes and chemical resistance for sulfate-rich environments.

Low heat cement vs Sulphate resisting cement Infographic

libmatt.com

libmatt.com