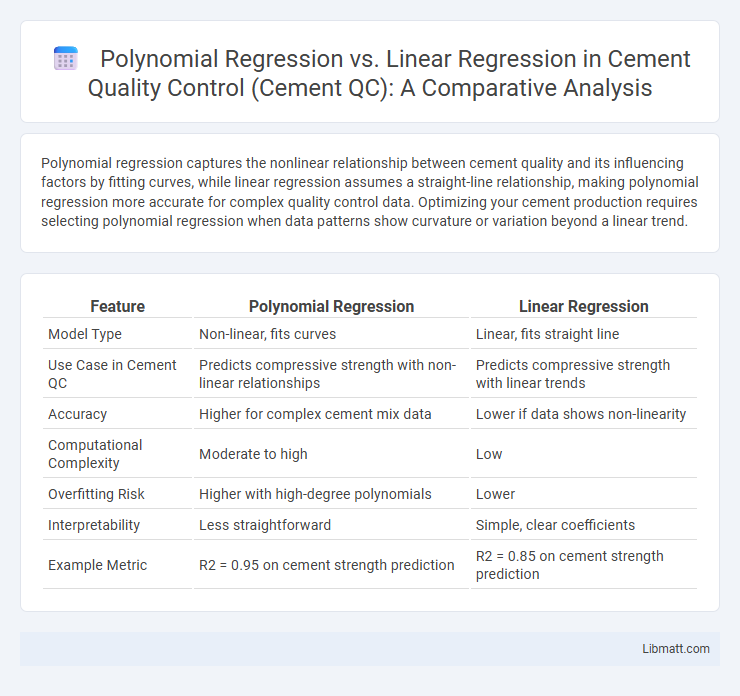

Polynomial regression captures the nonlinear relationship between cement quality and its influencing factors by fitting curves, while linear regression assumes a straight-line relationship, making polynomial regression more accurate for complex quality control data. Optimizing your cement production requires selecting polynomial regression when data patterns show curvature or variation beyond a linear trend.

Table of Comparison

| Feature | Polynomial Regression | Linear Regression |

|---|---|---|

| Model Type | Non-linear, fits curves | Linear, fits straight line |

| Use Case in Cement QC | Predicts compressive strength with non-linear relationships | Predicts compressive strength with linear trends |

| Accuracy | Higher for complex cement mix data | Lower if data shows non-linearity |

| Computational Complexity | Moderate to high | Low |

| Overfitting Risk | Higher with high-degree polynomials | Lower |

| Interpretability | Less straightforward | Simple, clear coefficients |

| Example Metric | R2 = 0.95 on cement strength prediction | R2 = 0.85 on cement strength prediction |

Introduction to Regression in Cement Quality Control

Regression analysis in cement quality control is essential for predicting key properties such as compressive strength based on variables like composition and curing time. Linear regression models assume a straight-line relationship between input factors and cement quality metrics, providing simplicity and interpretability for initial assessments. Polynomial regression captures more complex, non-linear interactions in the data, improving prediction accuracy for cement strength variations caused by intricate chemical and physical influences during production.

Fundamentals of Linear Regression

Linear regression models the relationship between a dependent variable and one or more independent variables by fitting a linear equation to observed data, making it suitable for predicting cement quality measures based on linear trends in raw material properties. It assumes a constant rate of change and minimizes the sum of squared residuals, providing interpretable coefficients that explain the impact of factors like water-to-cement ratio on strength. Your quality control process benefits from this straightforward approach when the relationship between variables is approximately linear, enabling efficient monitoring and adjustments.

Overview of Polynomial Regression

Polynomial regression enhances linear regression by modeling the relationship between the independent variable and the dependent variable as an nth-degree polynomial, offering greater flexibility to fit datasets with nonlinear patterns common in cement quality control tests. This method captures complex trends such as variations in cement strength or setting time under different curing conditions, which linear regression may oversimplify. Polynomial regression effectively minimizes error in prediction by adjusting coefficients for higher-degree terms, improving accuracy in predicting cement properties critical for quality assurance.

Application of Linear Regression in Cement QC

Linear regression in cement quality control is widely used to predict compressive strength based on input variables such as water-cement ratio, curing time, and temperature. This method helps establish straightforward relationships between key process parameters and cement properties, enabling quick adjustments to maintain quality standards. Real-time data from production lines feed linear models to monitor and optimize cement mix formulations, ensuring consistent product performance.

Application of Polynomial Regression in Cement QC

Polynomial regression enhances modeling accuracy in cement quality control by capturing nonlinear relationships between mixture components and material properties, such as compressive strength and setting time. This method improves prediction precision for complex chemical interactions that linear regression might oversimplify, enabling better optimization of cement formulations. Your quality control processes benefit from polynomial regression through more reliable assessment and adjustment of raw material proportions to meet specific performance criteria.

Strengths and Limitations of Linear Regression

Linear regression in cement quality control efficiently models relationships between variables with a clear, interpretable linear trend, making it ideal for initial analysis of compressive strength data. Its simplicity allows quick prediction and easy parameter estimation but is limited by its inability to capture non-linear patterns often present in the material properties and curing conditions. This constraint can lead to underfitting when complex interactions affect cement quality, necessitating polynomial regression for more accurate modeling of non-linear relationships.

Strengths and Limitations of Polynomial Regression

Polynomial regression offers enhanced flexibility over linear regression by modeling nonlinear relationships in cement quality control, capturing complex patterns between variables such as compressive strength and curing time. It is particularly effective when your data exhibits curvature, providing better fit and predictive accuracy, but risks overfitting with high-degree polynomials, reducing generalizability. Limitations include increased computational complexity and sensitivity to outliers, which can impact the robustness of predictions in cement quality assessments.

Comparative Analysis: Fit Accuracy in Cement Data

Polynomial regression demonstrates higher fit accuracy than linear regression in cement quality control data by capturing non-linear relationships between input variables such as clinker composition and compressive strength. Linear regression often underestimates the complexity of cement performance metrics, leading to larger residual errors and poorer predictions. Polynomial models reduce mean squared error significantly, enhancing predictive reliability for optimizing cement formulation and quality assurance.

Selecting the Right Regression Approach for Cement QC

Selecting the right regression approach for cement quality control hinges on understanding the data's complexity and the relationship between variables. Linear regression suits scenarios with a straightforward, linear relationship between input factors and cement properties, while polynomial regression better captures nonlinear patterns and variations in material characteristics. Your choice impacts prediction accuracy, process optimization, and ultimately, the durability and strength of cement products.

Conclusion: Optimizing Cement Quality with Regression Techniques

Polynomial regression captures complex nonlinear patterns in cement quality data, providing more accurate predictions than linear regression, which assumes a straight-line relationship. Your cement quality control benefits from polynomial models by better modeling variations caused by raw material inconsistencies and processing variables. Effective optimization using polynomial regression enhances durability and performance of cement products, ultimately improving production efficiency and product reliability.

Polynomial Regression vs Linear Regression (Cement QC) Infographic

libmatt.com

libmatt.com