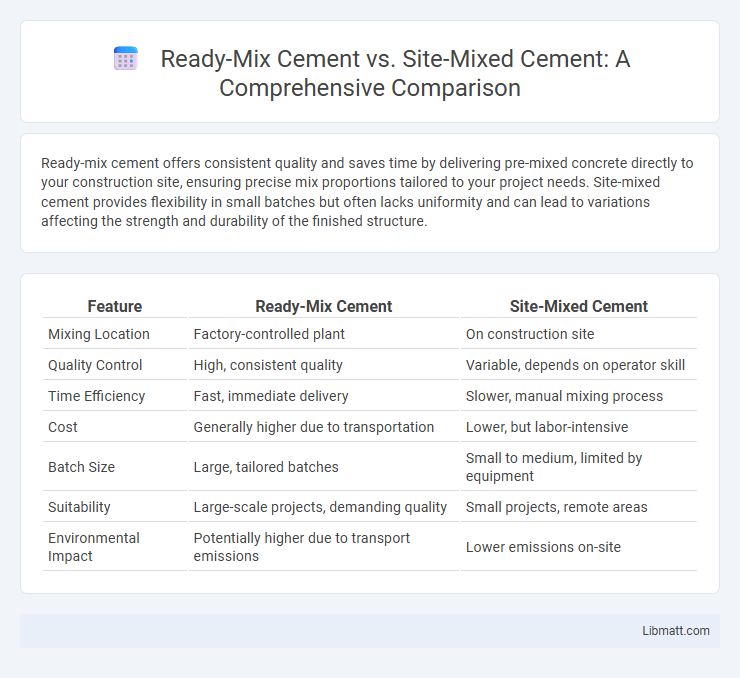

Ready-mix cement offers consistent quality and saves time by delivering pre-mixed concrete directly to your construction site, ensuring precise mix proportions tailored to your project needs. Site-mixed cement provides flexibility in small batches but often lacks uniformity and can lead to variations affecting the strength and durability of the finished structure.

Table of Comparison

| Feature | Ready-Mix Cement | Site-Mixed Cement |

|---|---|---|

| Mixing Location | Factory-controlled plant | On construction site |

| Quality Control | High, consistent quality | Variable, depends on operator skill |

| Time Efficiency | Fast, immediate delivery | Slower, manual mixing process |

| Cost | Generally higher due to transportation | Lower, but labor-intensive |

| Batch Size | Large, tailored batches | Small to medium, limited by equipment |

| Suitability | Large-scale projects, demanding quality | Small projects, remote areas |

| Environmental Impact | Potentially higher due to transport emissions | Lower emissions on-site |

Introduction to Ready-Mix vs Site-Mixed Cement

Ready-mix cement is a pre-mixed concrete prepared in factories under controlled conditions and delivered directly to construction sites, ensuring consistent quality and precise water-cement ratios. Site-mixed cement involves mixing raw materials such as cement, sand, gravel, and water manually at the construction location, which can lead to variable consistency and higher chances of human error. The choice between ready-mix and site-mixed cement impacts project timelines, labor costs, and structural integrity.

Understanding Ready-Mix Cement

Ready-mix cement is a pre-prepared blend of cement, aggregates, and water produced at a centralized batching plant to ensure consistent quality and precise proportions, reducing on-site labor and waste. Unlike site-mixed cement, which is mixed manually with variable accuracy, ready-mix cement offers increased efficiency, improved strength, and better workability for construction projects. Your choice of ready-mix cement guarantees compliance with industry standards and enhances overall project reliability.

Overview of Site-Mixed Cement

Site-mixed cement involves combining cement, sand, aggregate, and water directly at the construction site, allowing for on-demand adjustments to mix proportions. This method offers flexibility but requires skilled labor and consistent quality control to ensure strength and durability. Your project's success depends on accurate measurement and thorough mixing to achieve reliable concrete performance.

Key Differences Between Ready-Mix and Site-Mixed Cement

Ready-mix cement is prepared in a controlled factory environment and delivered to your construction site, ensuring consistent quality, precise water-cement ratios, and reduced labor costs. Site-mixed cement is made on-site by manually mixing raw materials, which can lead to variability in strength and workability due to inconsistent proportions and mixing methods. Choosing ready-mix cement improves efficiency, minimizes material wastage, and guarantees compliance with industry standards compared to unpredictable site-mixed cement.

Strength and Quality Comparison

Ready-mix cement ensures consistent strength and high-quality control due to precise batching in specialized plants, resulting in uniform concrete properties. Site-mixed cement often varies in quality and strength because of inconsistent material proportions and mixing conditions at the construction site. For your project, choosing ready-mix cement enhances reliability in achieving desired structural performance and durability.

Cost Analysis: Ready-Mix vs Site-Mixed Cement

Ready-mix cement often has higher upfront costs due to batching plant production and transportation, but it reduces labor expenses and material wastage compared to site-mixed cement. Site-mixed cement may appear cost-effective for small projects but involves increased labor, potential quality inconsistencies, and higher overall risk of rework. Your choice should consider project scale and quality control requirements to optimize cost efficiency between these two cement mixing methods.

Time Efficiency and Project Timelines

Ready-mix cement significantly improves time efficiency by delivering precise, pre-mixed concrete directly to construction sites, reducing mixing time and labor requirements. Site-mixed cement often leads to longer project timelines due to on-site batching, variability in mix quality, and additional preparation time. Choosing ready-mix cement helps streamline Your project schedule and ensures consistent quality for faster completion.

Environmental Impact and Sustainability

Ready-mix cement significantly reduces environmental impact by minimizing waste and lowering emissions through controlled factory production and optimized transport logistics. Site-mixed cement often leads to higher carbon footprints due to inefficient batching and increased material wastage during onsite mixing. Choosing ready-mix cement supports more sustainable construction practices by ensuring consistent quality and reducing overall resource consumption, benefiting your project's environmental goals.

Common Applications and Use Cases

Ready-mix cement is commonly used for large-scale construction projects like commercial buildings, bridges, and high-rise structures due to its consistent quality and precise mixture proportions. Site-mixed cement is preferred for smaller jobs, repairs, and remote locations where immediate batch preparation is feasible, allowing flexibility in mix adjustments. Your choice depends on project scale, desired quality control, and logistical considerations at the construction site.

Choosing the Right Cement Mix for Your Project

Ready-mix cement offers consistent quality and precise batching controlled by professional manufacturers, ensuring optimal strength and durability for your construction needs. Site-mixed cement provides flexibility and lower initial costs but requires skilled labor to achieve the correct proportions, which can impact the overall structural integrity. Choosing the right cement mix depends on your project size, budget, and quality requirements to achieve the best performance and longevity.

Ready-mix cement vs Site-mixed cement Infographic

libmatt.com

libmatt.com