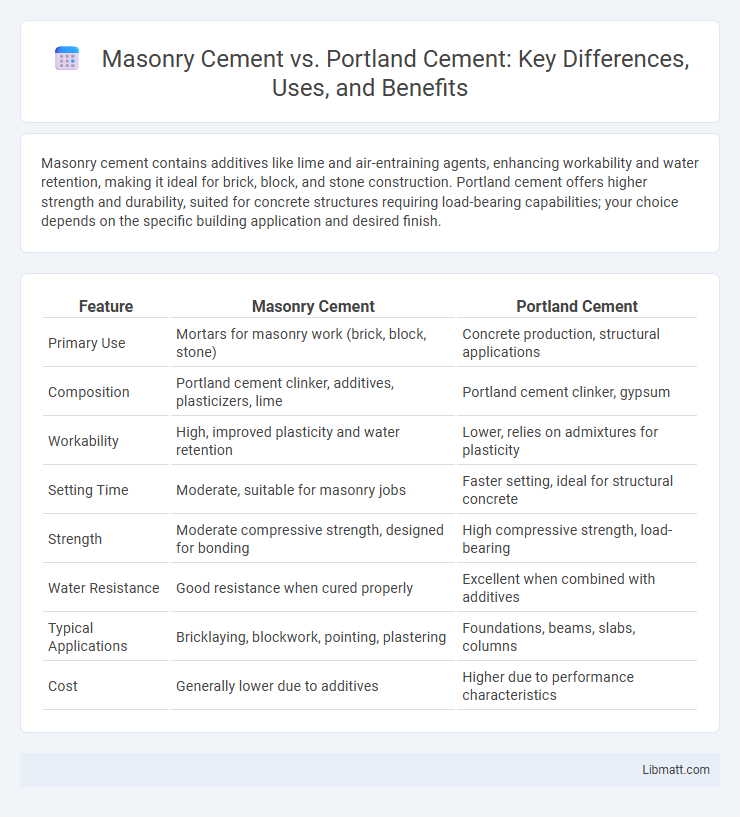

Masonry cement contains additives like lime and air-entraining agents, enhancing workability and water retention, making it ideal for brick, block, and stone construction. Portland cement offers higher strength and durability, suited for concrete structures requiring load-bearing capabilities; your choice depends on the specific building application and desired finish.

Table of Comparison

| Feature | Masonry Cement | Portland Cement |

|---|---|---|

| Primary Use | Mortars for masonry work (brick, block, stone) | Concrete production, structural applications |

| Composition | Portland cement clinker, additives, plasticizers, lime | Portland cement clinker, gypsum |

| Workability | High, improved plasticity and water retention | Lower, relies on admixtures for plasticity |

| Setting Time | Moderate, suitable for masonry jobs | Faster setting, ideal for structural concrete |

| Strength | Moderate compressive strength, designed for bonding | High compressive strength, load-bearing |

| Water Resistance | Good resistance when cured properly | Excellent when combined with additives |

| Typical Applications | Bricklaying, blockwork, pointing, plastering | Foundations, beams, slabs, columns |

| Cost | Generally lower due to additives | Higher due to performance characteristics |

Introduction to Masonry Cement and Portland Cement

Masonry cement is a blend of Portland cement, limestone, and other additives designed for improved workability and water retention in mortar applications, making it ideal for brick and block laying. Portland cement is a hydraulic binder composed primarily of clinker and gypsum, known for its high compressive strength and versatility in constructing concrete structures. Understanding the distinct composition and performance characteristics of masonry cement versus Portland cement is essential for selecting the appropriate material in masonry and concrete projects.

Composition Differences Between Masonry and Portland Cement

Masonry cement contains a blend of Portland cement, limestone, and additives such as plasticizers and air-entraining agents, which improve workability and water retention for masonry applications. Portland cement is primarily composed of clinker, gypsum, and minimal additives, resulting in higher strength and faster curing for structural concrete. The differing compositions influence their specific uses, with masonry cement optimized for mortar flexibility and durability, while Portland cement suits high-strength concrete requirements.

Manufacturing Processes Compared

Masonry cement is manufactured by blending Portland cement with limestone and other additives, which enhances workability and water retention specifically for masonry applications. Portland cement undergoes a more complex process involving the calcination of limestone and clay at high temperatures in a rotary kiln, producing clinker that is ground to a fine powder. Your choice between these cements should consider their manufacturing differences, as masonry cement is optimized for bricklaying and block work, while Portland cement offers higher strength for structural uses.

Strength and Durability Analysis

Masonry cement offers enhanced workability and flexibility, making it ideal for mortar in brick and block construction, while Portland cement provides higher compressive strength suitable for structural concrete applications. The durability of masonry cement is optimized for resisting weathering and shrinkage in masonry joints, whereas Portland cement exhibits superior resistance to mechanical stress and chemical attack in demanding environments. Your choice depends on the required balance between strength and long-term durability for the specific construction project.

Key Applications for Masonry Cement

Masonry cement is primarily used for mortar in bricklaying, block work, and stone veneer applications due to its enhanced workability and water retention properties. It provides superior bonding and flexibility compared to Portland cement, making it ideal for exterior walls, chimneys, and repairs where durability and weather resistance are critical. Used in both structural and non-structural masonry, masonry cement ensures strong adhesion and improved surface finish in residential and commercial construction projects.

Key Applications for Portland Cement

Portland cement is primarily used in structural concrete, reinforced concrete, and large-scale construction projects such as bridges, dams, and buildings due to its high compressive strength and durability. It is essential for creating foundations, paving, and precast concrete products where strength and longevity are critical. Masonry cement, in contrast, is tailored for mortar applications like bricklaying and blockwork, where workability and adhesion are prioritized over ultimate strength.

Workability and Setting Times

Masonry cement offers superior workability compared to Portland cement, making it easier to spread and shape for bricklaying and blockwork applications. Its setting time is generally faster, allowing quicker completion of masonry projects while maintaining strong bond strength. You can choose masonry cement for tasks requiring smooth consistency and timely curing, whereas Portland cement, with slower setting, suits structural work needing longer workability.

Cost Comparison and Availability

Masonry cement typically costs more per bag than Portland cement due to its added lime and plasticizers enhancing workability and durability. Portland cement enjoys widespread availability in most hardware stores and construction suppliers, making it a more accessible option for large-scale projects. Your choice between the two will depend on budget constraints and the specific requirements of the construction task.

Environmental Impact Considerations

Masonry cement typically has a lower environmental impact than Portland cement due to its blended composition, which includes limestone and other additives that reduce clinker content and carbon emissions during production. Portland cement production is energy-intensive and a major source of CO2 emissions, accounting for approximately 7% of global carbon dioxide output. Choosing masonry cement for your projects can contribute to sustainability efforts by decreasing your carbon footprint without compromising durability and performance.

Choosing the Right Cement for Your Project

Masonry cement is formulated with additives that enhance workability and bond strength, making it ideal for bricklaying and blockwork. Portland cement offers higher compressive strength and is better suited for structural concrete and heavy-duty applications. Selecting the right cement depends on the project's requirements for durability, flexibility, and finish quality.

Masonry cement vs Portland cement Infographic

libmatt.com

libmatt.com