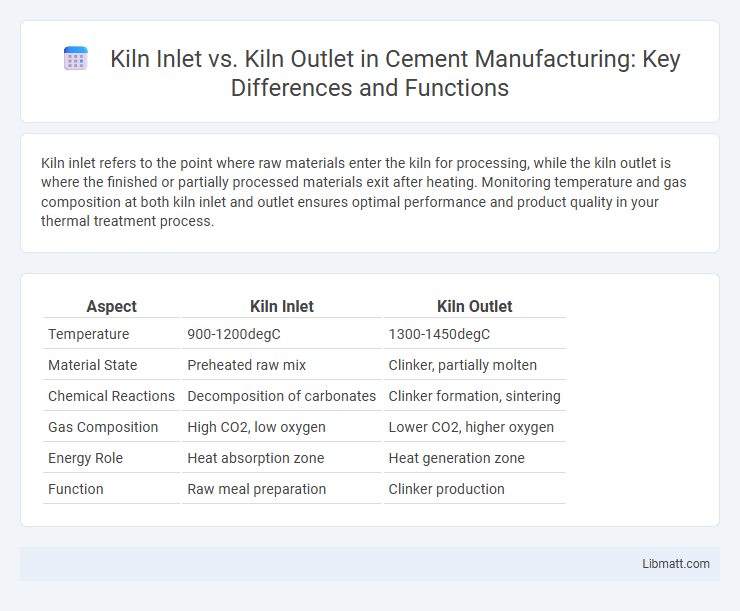

Kiln inlet refers to the point where raw materials enter the kiln for processing, while the kiln outlet is where the finished or partially processed materials exit after heating. Monitoring temperature and gas composition at both kiln inlet and outlet ensures optimal performance and product quality in your thermal treatment process.

Table of Comparison

| Aspect | Kiln Inlet | Kiln Outlet |

|---|---|---|

| Temperature | 900-1200degC | 1300-1450degC |

| Material State | Preheated raw mix | Clinker, partially molten |

| Chemical Reactions | Decomposition of carbonates | Clinker formation, sintering |

| Gas Composition | High CO2, low oxygen | Lower CO2, higher oxygen |

| Energy Role | Heat absorption zone | Heat generation zone |

| Function | Raw meal preparation | Clinker production |

Introduction to Kiln Inlet and Kiln Outlet

Kiln inlet refers to the section where raw materials enter the kiln for heating and processing, while kiln outlet is the exit point where processed materials and gases leave the kiln. Understanding the temperature, pressure, and composition differences between the inlet and outlet is crucial for optimizing kiln performance and product quality. Your control over the inlet and outlet parameters directly impacts energy efficiency and overall production outcomes.

Key Functions of Kiln Inlet

The Kiln Inlet plays a critical role in regulating the entry of raw materials and controlling the temperature for optimal combustion within the rotary kiln. It ensures consistent feed rates, allowing for even heat distribution and efficient chemical reactions during the calcination process. Maintaining precise conditions at the Kiln Inlet enhances the overall operational efficiency and product quality in cement manufacturing.

Essential Roles of Kiln Outlet

Kiln outlet plays a critical role in controlling the temperature and chemical composition of materials exiting the kiln, ensuring optimal product quality and process efficiency. Unlike the kiln inlet, which primarily introduces raw materials and combustion air, the kiln outlet is responsible for directing hot gases and processed materials to subsequent stages such as cooling and grinding. Your ability to monitor and adjust kiln outlet conditions directly impacts energy consumption, emissions control, and overall kiln performance.

Structural Differences: Inlet vs Outlet

The kiln inlet features a reinforced, insulated structure designed to withstand direct exposure to raw material feed and cooler air inflow, whereas the kiln outlet is constructed with heat-resistant materials to endure high temperatures and hot gas exhaust. Inlet sections often include feed chutes and air seals to minimize heat loss and material spillage, contrasting with outlet sections that incorporate cooling systems and gas vents for efficient emission handling. These structural differences optimize temperature control and material flow, enhancing kiln performance and longevity.

Temperature Profiles: Inlet vs Outlet Comparison

Kiln inlet temperatures typically range between 800degC and 1200degC, reflecting the initial combustion and heat input stage, while kiln outlet temperatures are generally lower, around 100degC to 300degC, indicating heat extraction and cooling processes. The temperature profile at the inlet shows sharp spikes due to fuel combustion, whereas the outlet profile exhibits a gradual decline as materials cool before discharge. Monitoring these temperature gradients is crucial for optimizing combustion efficiency and ensuring consistent product quality in rotary kiln operations.

Material Flow Dynamics at Inlet and Outlet

Kiln inlet experiences raw material entry where initial mixing, heating, and moisture removal occur, leading to dynamic fluctuations in particle velocity and temperature gradients that impact flow consistency. The kiln outlet manages processed material discharge, characterized by higher temperatures and reduced moisture content, with flow dynamics influenced by aggregate consolidation and cooler air infiltration. Optimizing material flow at both points is crucial for maintaining uniform kiln conditions and improving thermal efficiency in cement production processes.

Impact on Product Quality

Kiln inlet temperature directly affects the drying and chemical reactions of raw materials, influencing clinker formation and overall product quality in cement production. Kiln outlet temperature is critical for ensuring complete clinkerization, with insufficient outlet temperatures leading to underburnt clinker and poor strength development. Precise control of both inlet and outlet temperatures optimizes clinker quality, reducing defects and improving consistency in cement properties.

Maintenance Considerations for Inlet and Outlet

Kiln inlet maintenance prioritizes ensuring the proper sealing and temperature control to prevent heat loss and material bridging, which can disrupt the overall kiln operation. In contrast, kiln outlet maintenance focuses on managing buildup of clinker and dust, as well as monitoring refractory integrity to avoid damage from cooler temperatures and abrasive materials. Both areas require regular inspection and cleaning schedules to optimize kiln efficiency and extend equipment lifespan.

Common Issues and Troubleshooting

Kiln inlet and kiln outlet areas often face common issues such as temperature fluctuations, material buildup, and wear of refractory lining, which can lead to operational inefficiencies. Troubleshooting involves monitoring temperature profiles, inspecting refractory integrity frequently, and ensuring proper airflow and material feed rates to minimize blockages and uneven heating. Addressing these problems promptly can optimize your kiln performance and extend its service life.

Conclusion: Choosing Between Kiln Inlet and Outlet

Selecting between kiln inlet and kiln outlet depends primarily on the target phase of the kiln process; kiln inlet parameters influence raw material temperature and drying efficiency, while kiln outlet conditions reflect product quality and final clinker characteristics. Monitoring kiln inlet ensures optimal feed conditions and energy input, promoting uniform heating; kiln outlet measurement is crucial for assessing combustion completeness and adjusting operational controls. Effective control strategies integrate both inlet and outlet data to maximize kiln performance, reduce fuel consumption, and improve overall product consistency.

Kiln Inlet vs Kiln Outlet Infographic

libmatt.com

libmatt.com