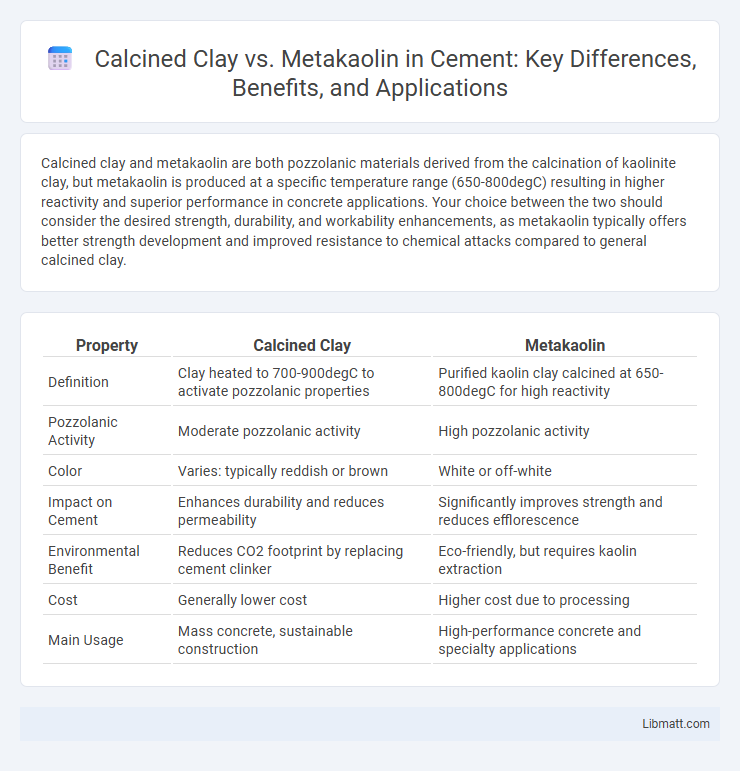

Calcined clay and metakaolin are both pozzolanic materials derived from the calcination of kaolinite clay, but metakaolin is produced at a specific temperature range (650-800degC) resulting in higher reactivity and superior performance in concrete applications. Your choice between the two should consider the desired strength, durability, and workability enhancements, as metakaolin typically offers better strength development and improved resistance to chemical attacks compared to general calcined clay.

Table of Comparison

| Property | Calcined Clay | Metakaolin |

|---|---|---|

| Definition | Clay heated to 700-900degC to activate pozzolanic properties | Purified kaolin clay calcined at 650-800degC for high reactivity |

| Pozzolanic Activity | Moderate pozzolanic activity | High pozzolanic activity |

| Color | Varies: typically reddish or brown | White or off-white |

| Impact on Cement | Enhances durability and reduces permeability | Significantly improves strength and reduces efflorescence |

| Environmental Benefit | Reduces CO2 footprint by replacing cement clinker | Eco-friendly, but requires kaolin extraction |

| Cost | Generally lower cost | Higher cost due to processing |

| Main Usage | Mass concrete, sustainable construction | High-performance concrete and specialty applications |

Introduction to Calcined Clay and Metakaolin

Calcined clay and metakaolin are highly reactive pozzolanic materials derived from kaolinite clay through thermal treatment processes. Calcined clay is produced by heating kaolinite to moderate temperatures, which enhances its reactivity and suitability as a supplementary cementitious material in concrete. Metakaolin results from calcining kaolinite at a higher temperature range, yielding a purer amorphous aluminosilicate phase that significantly improves the strength and durability of your concrete formulations.

Understanding the Calcination Process

The calcination process transforms raw clay minerals into reactive materials by heating them at high temperatures, typically between 600degC and 900degC, driving off chemically bound water and altering their physical and chemical structure. Calcined clay includes various types of clays subjected to this thermal treatment, while metakaolin is a highly purified form produced by calcining kaolin clay under controlled conditions, resulting in enhanced pozzolanic activity. Understanding this process is crucial for optimizing your selection between calcined clay and metakaolin for concrete performance and sustainability.

Chemical Composition Comparison

Calcined clay primarily contains kaolinite, which chemically transforms into amorphous silica and alumina during calcination, while metakaolin is a highly reactive pozzolanic material rich in these amorphous phases. The chemical composition of calcined clay includes a mix of silica (SiO2), alumina (Al2O3), and iron oxides (Fe2O3), typically with lower reactive silica content compared to metakaolin. Understanding these chemical differences helps you select the optimal material for enhancing concrete's durability and strength through improved pozzolanic activity.

Physical Properties: Calcined Clay vs Metakaolin

Calcined clay typically exhibits a higher specific surface area and greater porosity compared to metakaolin, influencing its reactivity and water demand in cementitious mixtures. Metakaolin's finer particle size and more uniform morphology contribute to enhanced pozzolanic activity and improved mechanical strength in concrete applications. Differences in physical properties such as particle shape, surface texture, and density directly impact workability, rheology, and durability performance of blended cements using these materials.

Performance in Concrete Applications

Calcined clay and metakaolin significantly enhance concrete performance by improving strength, durability, and resistance to chemical attacks. Metakaolin, a highly reactive pozzolan derived from kaolin clay, offers superior pozzolanic activity resulting in enhanced compressive strength and reduced permeability. Calcined clay, while effective in increasing durability and reducing environmental impact, generally exhibits lower reactivity compared to metakaolin, making metakaolin preferable for high-performance concrete mixes.

Pozzolanic Activity and Strength Development

Calcined clay exhibits significant pozzolanic activity due to its high content of reactive silica and alumina, which enhances the hydration process and contributes to long-term strength development in concrete. Metakaolin, produced by the controlled calcination of kaolin clay at temperatures around 650-800degC, has a highly amorphous structure that provides superior pozzolanic reactivity and accelerates early strength gain compared to raw calcined clay. Both materials improve durability and reduce permeability in concrete, but metakaolin generally delivers higher initial strength and improved microstructural refinement.

Durability and Resistance Features

Calcined clay and metakaolin both enhance concrete durability by improving resistance to chemical attacks and reducing permeability. Metakaolin exhibits superior pozzolanic activity, leading to denser microstructure and increased resistance to sulfate and chloride ingress. Calcined clay provides cost-effective durability enhancements, particularly in mitigating alkali-silica reactions and enhancing long-term strength.

Environmental Impact and Sustainability

Calcined clay and metakaolin both improve concrete durability and reduce carbon footprint by replacing traditional cement, but metakaolin requires higher energy for its production due to calcination at around 750-850degC compared to lower temperatures for general calcined clay. Using your choice of SCM (Supplementary Cementitious Material) can influence sustainability goals, as calcined clay sourced locally minimizes transportation emissions, enhancing environmental benefits. Life cycle assessments reveal that calcined clay often offers a more balanced approach to reducing CO2 emissions and preserving natural resources in concrete production.

Cost and Availability Factors

Calcined clay is generally more cost-effective than metakaolin due to its simpler production process and widespread availability from abundant raw clay deposits. Metakaolin requires higher quality kaolin clay and more controlled calcination, resulting in increased processing costs and limited regional availability. Your choice between the two should consider both budget constraints and local supply conditions to optimize material performance and project economics.

Selecting the Right Supplementary Cementitious Material

Selecting the right supplementary cementitious material between calcined clay and metakaolin involves assessing their reactivity, particle size, and impact on concrete durability. Calcined clay, rich in kaolinite, offers cost-effective pozzolanic properties and improves strength and durability through increased alumina content, while metakaolin provides higher reactivity and enhanced early-age strength due to its more refined calcination process. Evaluating factors such as project budget, desired mechanical performance, and environmental impact is crucial to determine the optimal SCM for concrete mix design.

Calcined Clay vs Metakaolin Infographic

libmatt.com

libmatt.com