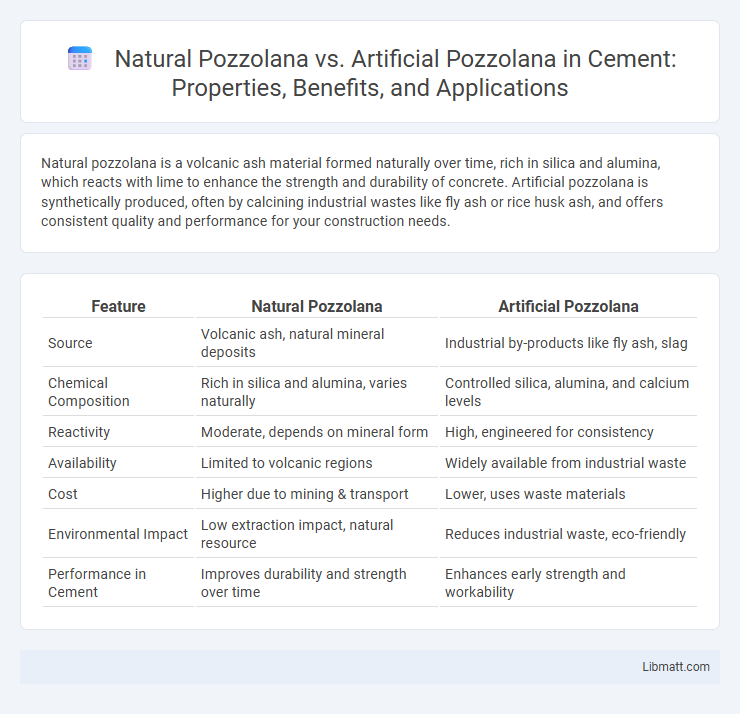

Natural pozzolana is a volcanic ash material formed naturally over time, rich in silica and alumina, which reacts with lime to enhance the strength and durability of concrete. Artificial pozzolana is synthetically produced, often by calcining industrial wastes like fly ash or rice husk ash, and offers consistent quality and performance for your construction needs.

Table of Comparison

| Feature | Natural Pozzolana | Artificial Pozzolana |

|---|---|---|

| Source | Volcanic ash, natural mineral deposits | Industrial by-products like fly ash, slag |

| Chemical Composition | Rich in silica and alumina, varies naturally | Controlled silica, alumina, and calcium levels |

| Reactivity | Moderate, depends on mineral form | High, engineered for consistency |

| Availability | Limited to volcanic regions | Widely available from industrial waste |

| Cost | Higher due to mining & transport | Lower, uses waste materials |

| Environmental Impact | Low extraction impact, natural resource | Reduces industrial waste, eco-friendly |

| Performance in Cement | Improves durability and strength over time | Enhances early strength and workability |

Introduction to Pozzolanic Materials

Pozzolanic materials are significant in enhancing the durability and strength of concrete by reacting with calcium hydroxide to form additional cementitious compounds. Natural pozzolana is derived from volcanic ash and other natural sources, whereas artificial pozzolana is produced through industrial by-products like fly ash or silica fume. Understanding the origin and composition of these pozzolanic materials helps you select the appropriate option for sustainable and high-performance construction.

Defining Natural Pozzolana

Natural pozzolana is a volcanic ash or pyroclastic material rich in silica and alumina, which reacts chemically with calcium hydroxide in the presence of moisture to form compounds possessing cementitious properties. It originates from natural geological processes, distinguishing it from artificial pozzolana, which is synthetically produced through industrial by-products such as fly ash or calcined clay. The intrinsic mineral composition and amorphous nature of natural pozzolana significantly contribute to its effectiveness as a supplementary cementitious material in concrete applications.

Defining Artificial Pozzolana

Artificial pozzolana is a man-made pozzolanic material produced through industrial processes such as calcination or grinding of by-products like fly ash, silica fume, or slag. Unlike natural pozzolana, which originates from volcanic ash deposits, artificial pozzolana offers consistent chemical composition and enhanced reactivity, improving the strength and durability of cement-based materials. Your choice of artificial pozzolana can optimize construction performance by providing better control over cement hydration and reducing environmental impact through recycling industrial waste.

Sources and Composition of Natural Pozzolana

Natural pozzolana originates from volcanic ash and other naturally occurring siliceous materials rich in silica and alumina, typically found near volcanic regions such as Italy, Indonesia, and India. Its composition includes reactive silicates and aluminates that chemically react with calcium hydroxide in cement to form strong, durable compounds enhancing concrete performance. Understanding the sources and composition of natural pozzolana helps you select efficient, eco-friendly additives for sustainable construction projects.

Production and Types of Artificial Pozzolana

Natural pozzolana is derived from volcanic ash deposits formed over centuries, while artificial pozzolana is produced by industrial processes commonly using calcined clay, fly ash from coal combustion, or silica fume generated in silicon metal production. Artificial pozzolana types include fly ash, which enhances concrete durability and workability, and silica fume, known for its ultrafine particles that significantly increase strength and reduce permeability. Production of artificial pozzolana involves thermal treatment or controlled industrial by-products, enabling consistent material properties and widespread availability beyond volcanic regions.

Chemical and Physical Properties Comparison

Natural pozzolana consists primarily of volcanic ash containing silica, alumina, and iron oxide, which react with calcium hydroxide to form cementitious compounds, while artificial pozzolana, often produced from calcined clays or industrial byproducts like fly ash, features a more controlled chemical composition tailored for specific performance characteristics. Physically, natural pozzolana particles tend to have irregular shapes and varied sizes, contributing to improved bonding but less uniformity, whereas artificial pozzolana particles are generally more consistent and spherical, enhancing workability and strength development in concrete mixes. Understanding these chemical and physical distinctions helps optimize Your choice of pozzolanic materials for durability, strength, and sustainability in construction applications.

Performance in Concrete and Mortar

Natural pozzolana enhances concrete and mortar by providing excellent workability, improved durability, and resistance to chemical attacks due to its volcanic origin and fine particle size. Artificial pozzolana, often produced from industrial by-products like fly ash or slag, offers consistent quality and higher pozzolanic activity, leading to faster strength gain and better long-term performance in cementitious mixtures. Both types improve mechanical properties and reduce permeability, but artificial pozzolana typically delivers superior performance in high-strength and specialized structural applications.

Environmental Impact and Sustainability

Natural pozzolana, derived from volcanic ash, offers a lower carbon footprint because it requires minimal processing compared to Artificial pozzolana, which is manufactured from industrial by-products like fly ash or blast furnace slag and may involve energy-intensive production. Your choice of natural pozzolana supports sustainability by reducing greenhouse gas emissions and conserving natural resources, while artificial pozzolana promotes recycling of industrial waste, mitigating landfill impact. Both types contribute to eco-friendly construction, but natural pozzolana generally presents a more environmentally harmonious option.

Cost and Availability Analysis

Natural pozzolana, derived from volcanic ash deposits, generally offers lower cost due to its abundant availability in regions with volcanic activity, reducing transportation expenses. Artificial pozzolana, produced from industrial by-products like fly ash or slag, can incur higher costs linked to processing and quality control but ensures more consistent supply in areas lacking natural sources. Your choice between natural and artificial pozzolana will depend on local resource availability and budget constraints, impacting overall project cost efficiency.

Conclusion: Choosing the Right Pozzolana

Natural pozzolana, derived from volcanic ash, offers consistent chemical properties and sustainability benefits, while artificial pozzolana, produced through industrial processes, provides tailored performance and faster setting times. Your choice depends on project requirements such as strength, availability, environmental impact, and cost-effectiveness. Understanding the specific advantages of each type ensures optimal concrete durability and efficiency.

Natural pozzolana vs Artificial pozzolana Infographic

libmatt.com

libmatt.com