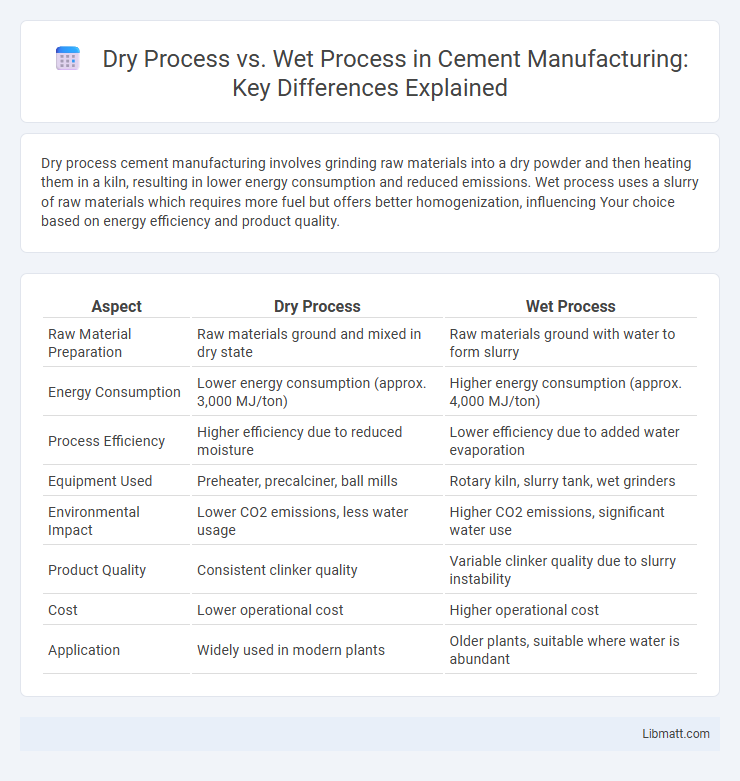

Dry process cement manufacturing involves grinding raw materials into a dry powder and then heating them in a kiln, resulting in lower energy consumption and reduced emissions. Wet process uses a slurry of raw materials which requires more fuel but offers better homogenization, influencing Your choice based on energy efficiency and product quality.

Table of Comparison

| Aspect | Dry Process | Wet Process |

|---|---|---|

| Raw Material Preparation | Raw materials ground and mixed in dry state | Raw materials ground with water to form slurry |

| Energy Consumption | Lower energy consumption (approx. 3,000 MJ/ton) | Higher energy consumption (approx. 4,000 MJ/ton) |

| Process Efficiency | Higher efficiency due to reduced moisture | Lower efficiency due to added water evaporation |

| Equipment Used | Preheater, precalciner, ball mills | Rotary kiln, slurry tank, wet grinders |

| Environmental Impact | Lower CO2 emissions, less water usage | Higher CO2 emissions, significant water use |

| Product Quality | Consistent clinker quality | Variable clinker quality due to slurry instability |

| Cost | Lower operational cost | Higher operational cost |

| Application | Widely used in modern plants | Older plants, suitable where water is abundant |

Introduction to Cement Manufacturing Processes

Cement manufacturing involves two primary processes: dry and wet, each differing in material preparation and energy consumption. The dry process grinds raw materials into a dry powder before heating, offering higher energy efficiency and lower emissions compared to the wet process, which uses a slurry mixture of raw materials. Understanding these methods helps optimize Your cement production for cost-effectiveness and environmental compliance.

Overview of the Dry Process

The dry process in cement manufacturing involves grinding raw materials into a fine powder and mixing them in a dry state before feeding the mixture into the kiln. This method is more energy-efficient compared to the wet process because it eliminates the need to evaporate water, reducing fuel consumption significantly. Your plant can benefit from lower operational costs and improved environmental performance by adopting the dry process for cement production.

Overview of the Wet Process

The wet process in cement manufacturing involves mixing raw materials with water to create a slurry, enhancing homogenization before kiln heating. This method offers better mixing and easier material handling but requires higher energy consumption due to the evaporation of water in the kiln. Your choice of the wet process depends on factors like raw material consistency and energy availability.

Key Differences between Dry and Wet Processes

The key differences between dry and wet processes in cement manufacturing lie in the moisture content of raw materials and energy efficiency; the dry process uses dry raw materials ground and blended in a dry state, while the wet process involves mixing raw materials with water to form a slurry. The dry process consumes less energy due to the absence of water evaporation, making it more environmentally friendly and cost-effective. Your choice between these processes depends on factors like raw material characteristics, plant capacity, and energy considerations.

Raw Material Preparation in Both Methods

In cement manufacturing, the dry process involves grinding raw materials into a fine powder and blending them in a dry state before heating in the kiln, optimizing energy efficiency and reducing moisture content. The wet process mixes raw materials with water to form a slurry, facilitating homogenization but requiring higher fuel consumption due to the need for evaporating water during kiln firing. Raw material preparation in the dry process uses preheaters and precalciners to enhance thermal efficiency, while the wet process relies on slurry tanks and pumps to maintain consistency before feeding the kiln.

Energy Consumption Comparison

The dry process in cement manufacturing consumes significantly less energy than the wet process because it eliminates the need to evaporate water from the raw materials, leading to lower fuel costs and reduced CO2 emissions. Wet process plants require up to 30-40% more thermal energy due to the slurry's high moisture content, increasing overall operational expenses. Optimizing Your production by choosing the dry process enhances energy efficiency and supports sustainable cement manufacturing goals.

Environmental Impact: Dry vs Wet Process

The dry process in cement manufacturing uses less energy and produces lower CO2 emissions compared to the wet process, which requires significant energy to evaporate water content. Your choice of the dry process contributes to reduced environmental pollution and lower greenhouse gas emissions. Wet process plants typically generate more wastewater and higher dust emissions, increasing their environmental footprint.

Quality of Cement Produced

The dry process of cement manufacturing typically produces cement with more consistent chemical composition and higher quality due to precise control of raw material blending and lower moisture content. In contrast, the wet process often results in cement with variable quality because of the added water, which can cause uneven chemical reactions and increased energy consumption. Consequently, the dry process is preferred for producing superior cement with enhanced durability and strength.

Cost Efficiency and Economic Considerations

The dry process in cement manufacturing generally offers greater cost efficiency due to lower energy consumption, as it eliminates the need for drying raw materials, reducing fuel expenses significantly compared to the wet process. Economically, the dry process supports higher production rates and lower operational costs, making it more favorable for large-scale plants aiming to maximize profitability. Wet process plants incur higher costs from water handling and evaporation, leading to increased energy use and maintenance expenses, which can impact overall economic viability negatively.

Industry Trends and Future Perspectives

The dry process dominates cement manufacturing due to its energy efficiency and lower carbon emissions compared to the wet process, aligning with the industry's shift toward sustainability and regulatory compliance. Recent trends emphasize integrating advanced technologies like preheater towers and rotary kilns to enhance energy utilization and reduce operational costs. Future perspectives indicate a gradual phase-out of the wet process as manufacturers prioritize eco-friendly methods and innovations such as alternative fuels and waste heat recovery systems to meet global climate targets.

Dry process vs Wet process (cement manufacturing) Infographic

libmatt.com

libmatt.com