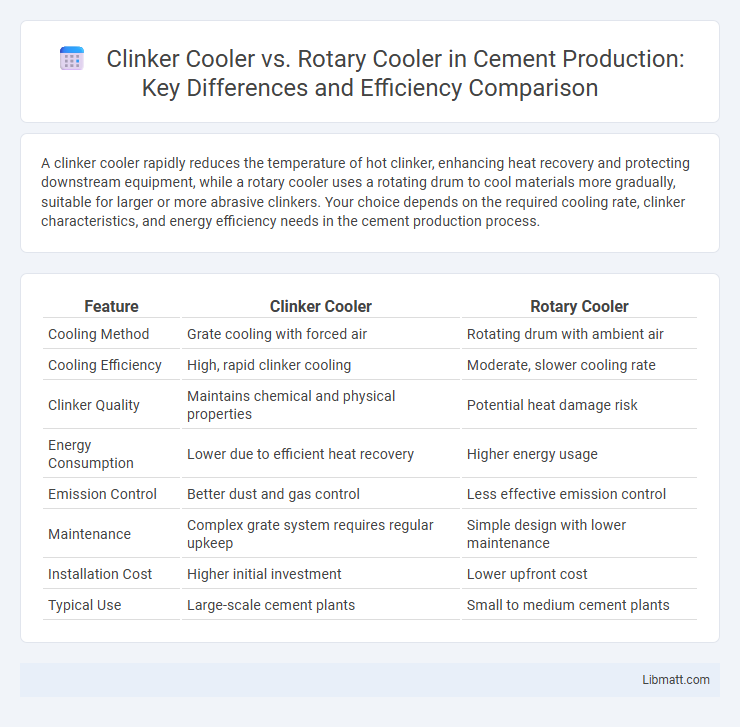

A clinker cooler rapidly reduces the temperature of hot clinker, enhancing heat recovery and protecting downstream equipment, while a rotary cooler uses a rotating drum to cool materials more gradually, suitable for larger or more abrasive clinkers. Your choice depends on the required cooling rate, clinker characteristics, and energy efficiency needs in the cement production process.

Table of Comparison

| Feature | Clinker Cooler | Rotary Cooler |

|---|---|---|

| Cooling Method | Grate cooling with forced air | Rotating drum with ambient air |

| Cooling Efficiency | High, rapid clinker cooling | Moderate, slower cooling rate |

| Clinker Quality | Maintains chemical and physical properties | Potential heat damage risk |

| Energy Consumption | Lower due to efficient heat recovery | Higher energy usage |

| Emission Control | Better dust and gas control | Less effective emission control |

| Maintenance | Complex grate system requires regular upkeep | Simple design with lower maintenance |

| Installation Cost | Higher initial investment | Lower upfront cost |

| Typical Use | Large-scale cement plants | Small to medium cement plants |

Introduction to Clinker Coolers and Rotary Coolers

Clinker coolers and rotary coolers are essential equipment in cement manufacturing used to reduce the temperature of hot clinker discharged from the kiln. Clinker coolers typically use an air cooling process with vibrating grates or traveling grates to cool the clinker while recovering heat for kiln operations. Rotary coolers operate by tumbling clinker in a rotating drum, providing uniform cooling and particle size reduction but with different heat recovery efficiencies compared to clinker coolers.

Key Functions in Cement Production

Clinker coolers and rotary coolers serve critical roles in cement production, with clinker coolers rapidly reducing the temperature of freshly formed clinker from around 1400degC to manageable levels for further processing and storage. Rotary coolers, however, are primarily utilized to cool raw materials or byproducts through continuous tumbling in a rotating drum, enhancing heat recovery and material handling efficiency. Your choice between these coolers depends on specific plant requirements related to heat management and production throughput.

Design Overview: Clinker Cooler

The clinker cooler features a stationary grate system designed for efficient heat recovery and clinker cooling in cement plants. Its robust construction ensures uniform air distribution, promoting effective temperature reduction of hot clinker directly from the kiln. Your choice of a clinker cooler supports improved energy efficiency and prolonged equipment lifespan compared to rotary coolers.

Design Overview: Rotary Cooler

The rotary cooler features a cylindrical drum design that rotates to facilitate heat exchange and clinker cooling efficiently. Its inclined structure allows clinker to move continuously while exposed to ambient air, promoting consistent temperature reduction. This design optimizes heat recovery and ensures uniform clinker particle cooling compared to static cooling systems.

Operational Principles Compared

Clinker coolers utilize a series of grates or beds through which air flows upward to cool the clinker by direct contact, optimizing heat recovery and improving energy efficiency. Rotary coolers operate by rotating a cylindrical drum where clinker is cooled by ambient air flowing counter-currently, providing uniform cooling and reducing clinker dust. Your choice between these technologies depends on operational needs, plant size, and desired thermal performance.

Efficiency and Energy Consumption

Clinker coolers offer higher efficiency by rapidly reducing the temperature of clinker while recovering waste heat, which lowers overall energy consumption in cement production. Rotary coolers, while simpler in design, generally have lower heat recovery rates and consume more energy due to longer cooling times and less effective heat exchange. Choosing the right cooler impacts your plant's energy footprint and operational costs significantly by optimizing thermal efficiency.

Maintenance Requirements and Lifespan

Clinker coolers generally have lower maintenance requirements due to their simpler design with fewer moving parts, resulting in less frequent downtime and reduced operational costs. Rotary coolers, however, require regular inspection and maintenance of bearings, seals, and gearboxes to prevent wear and prolong equipment lifespan. Your choice between the two should consider the trade-off between maintenance intensity and expected operational longevity, where clinker coolers typically offer longer service life under consistent conditions.

Environmental Impact and Emission Control

Clinker coolers typically offer better emission control due to their enclosed design, which reduces dust and particulate matter release compared to rotary coolers. Rotary coolers often have higher fugitive emissions because of their open structure, leading to greater environmental impact without additional control measures. Selecting the right cooler can significantly enhance Your plant's compliance with environmental regulations and lower pollutant discharge.

Cost Comparison and Investment Considerations

Clinker coolers typically offer lower initial investment costs due to simpler design and easier installation compared to rotary coolers, which involve higher capital expenditure for complex mechanisms and maintenance. Operating costs for clinker coolers are generally reduced as they consume less energy and require less maintenance, enhancing long-term cost efficiency. Investment decisions should weigh clinker coolers' cost-effectiveness and simpler upkeep against rotary coolers' advantages in handling larger volumes and better heat recovery potential.

Choosing the Right Cooler for Your Cement Plant

Selecting between a clinker cooler and a rotary cooler greatly impacts your cement plant's efficiency and product quality. Clinker coolers, such as grate coolers, offer faster cooling rates and improved energy recovery, enhancing thermal efficiency and clinker strength. Your choice depends on factors like plant capacity, fuel type, and maintenance requirements, with clinker coolers generally preferred for modern, high-capacity operations.

Clinker cooler vs Rotary cooler Infographic

libmatt.com

libmatt.com