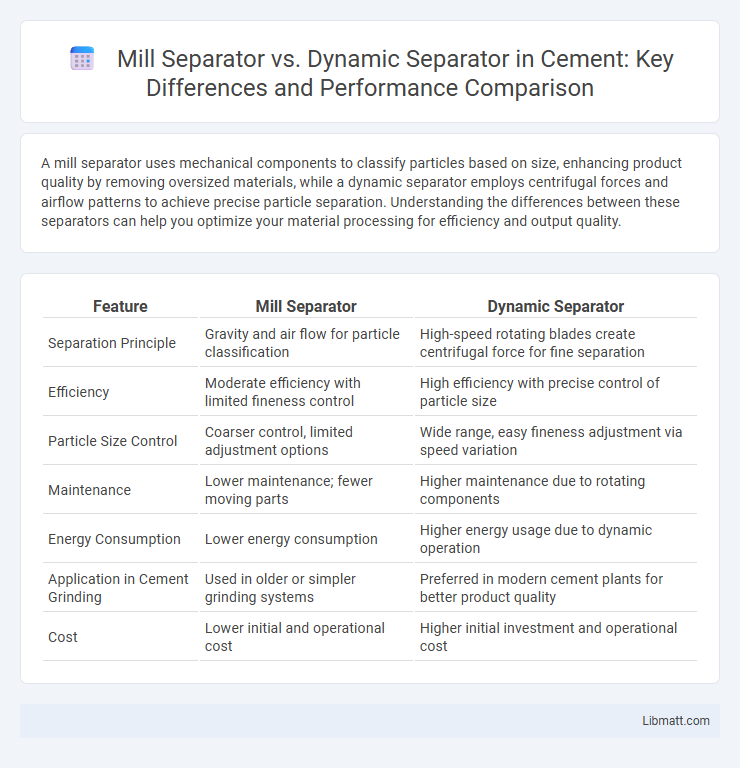

A mill separator uses mechanical components to classify particles based on size, enhancing product quality by removing oversized materials, while a dynamic separator employs centrifugal forces and airflow patterns to achieve precise particle separation. Understanding the differences between these separators can help you optimize your material processing for efficiency and output quality.

Table of Comparison

| Feature | Mill Separator | Dynamic Separator |

|---|---|---|

| Separation Principle | Gravity and air flow for particle classification | High-speed rotating blades create centrifugal force for fine separation |

| Efficiency | Moderate efficiency with limited fineness control | High efficiency with precise control of particle size |

| Particle Size Control | Coarser control, limited adjustment options | Wide range, easy fineness adjustment via speed variation |

| Maintenance | Lower maintenance; fewer moving parts | Higher maintenance due to rotating components |

| Energy Consumption | Lower energy consumption | Higher energy usage due to dynamic operation |

| Application in Cement Grinding | Used in older or simpler grinding systems | Preferred in modern cement plants for better product quality |

| Cost | Lower initial and operational cost | Higher initial investment and operational cost |

Introduction to Mill Separator and Dynamic Separator

Mill separators use airflow to classify particles based on size and density, optimizing material recovery in grinding circuits. Dynamic separators incorporate adjustable rotating blades or vanes to enhance separation efficiency by precisely controlling particle size distribution. Your choice between mill and dynamic separators depends on the desired product quality and process requirements in mineral processing or cement production.

Key Functions of Mill Separator

The key functions of a mill separator include efficiently classifying fine particles from coarse ones to enhance grinding efficiency and product quality in mineral processing. It uses static design elements like blades or rotating cages to separate particles based on size and density, ensuring optimal material flow within the grinding circuit. Your choice between a mill separator and a dynamic separator depends on the specific particle size distribution and throughput requirements of your operation.

Essential Features of Dynamic Separator

Dynamic separators feature adjustable rotor blades that optimize particle classification efficiency by controlling airflow velocity and turbulence, resulting in precise separation of fine and coarse materials. Unlike traditional mill separators, dynamic separators offer real-time adaptability to varying feed rates and material characteristics, enhancing overall milling performance. Their design minimizes energy consumption while maintaining high throughput, making them essential for improving product quality in mineral processing and cement industries.

Comparative Working Principles

Mill separators utilize static blades or vanes to classify particles based on size and centrifugal force, allowing fine particles to be separated from coarse ones through gravitational settling and inertia differences. Dynamic separators employ rotating rotors or variable-speed fans generating airflow patterns that actively lift and separate particles by density and aerodynamic properties, enabling more precise control over product fineness and particle distribution. The key difference lies in mill separators relying on passive classification through mechanical separation, while dynamic separators leverage centrifugal and aerodynamic forces for enhanced classification efficiency.

Efficiency in Material Separation

Dynamic separators achieve higher efficiency in material separation compared to mill separators by employing advanced aerodynamic design and adjustable rotor speeds. Mill separators rely on fixed mechanical components which often result in less precise particle classification and increased energy consumption. Optimized dynamic separators reduce fine particle recirculation, enhancing overall separation performance and operational cost-effectiveness in mineral processing and grinding circuits.

Energy Consumption Differences

Mill separators typically consume less energy compared to dynamic separators due to their simpler design and lower operational speed. Dynamic separators require additional power to drive their rotating components, increasing overall energy consumption in grinding circuits. Energy efficiency comparisons indicate that choosing mill separators can lead to significant reductions in power usage and operational costs.

Installation and Maintenance Considerations

Mill separators require straightforward installation with minimal structural modifications, making them suitable for retrofitting existing systems, and their maintenance involves periodic inspection and cleaning to ensure efficient particle classification. Dynamic separators, though more complex to install due to additional rotating components and precise alignment needs, offer improved control over separation efficiency but demand regular maintenance of moving parts such as bearings and rotor blades for optimal performance. Your choice between the two should consider the balance between installation simplicity and ongoing maintenance intensity to maximize operational uptime.

Impact on Product Quality

The Mill separator enhances product quality by efficiently classifying fine particles, resulting in a consistent particle size distribution that improves downstream processing and product uniformity. The Dynamic separator offers superior flexibility and control over particle cut points through adjustable rotor speeds, enabling precise separation and higher purity levels in the final product. Both separators directly influence product quality by optimizing particle size and reducing impurities, but the Dynamic separator provides greater adaptability for varying feed materials and product specifications.

Cost Implications and ROI

Mill separators typically have lower initial capital costs and simpler designs, resulting in reduced upfront investment compared to dynamic separators. However, dynamic separators offer higher efficiency and enhanced particle classification, which can lead to improved product quality and increased throughput, positively impacting long-term return on investment (ROI). Evaluating operational costs, maintenance frequency, and performance improvements is crucial to determine the most cost-effective solution for specific milling applications.

Choosing the Right Separator for Your Plant

Choosing the right separator for your plant depends on factors such as feed material characteristics, desired product fineness, and operational efficiency. Mill separators are ideal for coarse grinding applications with lower airflow requirements, while dynamic separators provide precise particle classification and higher efficiency for fine powders. Assess your plant's capacity, energy consumption goals, and maintenance preferences to ensure optimal separator performance and product quality.

Mill separator vs Dynamic separator Infographic

libmatt.com

libmatt.com