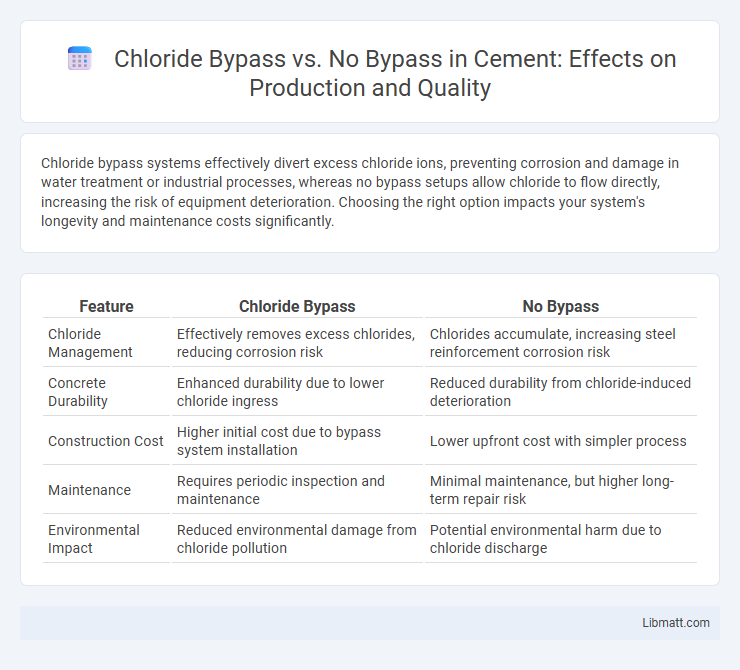

Chloride bypass systems effectively divert excess chloride ions, preventing corrosion and damage in water treatment or industrial processes, whereas no bypass setups allow chloride to flow directly, increasing the risk of equipment deterioration. Choosing the right option impacts your system's longevity and maintenance costs significantly.

Table of Comparison

| Feature | Chloride Bypass | No Bypass |

|---|---|---|

| Chloride Management | Effectively removes excess chlorides, reducing corrosion risk | Chlorides accumulate, increasing steel reinforcement corrosion risk |

| Concrete Durability | Enhanced durability due to lower chloride ingress | Reduced durability from chloride-induced deterioration |

| Construction Cost | Higher initial cost due to bypass system installation | Lower upfront cost with simpler process |

| Maintenance | Requires periodic inspection and maintenance | Minimal maintenance, but higher long-term repair risk |

| Environmental Impact | Reduced environmental damage from chloride pollution | Potential environmental harm due to chloride discharge |

Introduction to Chloride Bypass and No Bypass

Chloride bypass systems redirect chloride ions around sensitive equipment to prevent corrosion, enhancing operational longevity and safety. No bypass involves direct exposure of equipment to chloride ions, increasing risks of corrosion and maintenance needs. Understanding the differences between chloride bypass and no bypass helps you determine the best strategy for protecting infrastructure in chloride-rich environments.

Understanding Chloride Removal in Water Treatment

Chloride bypass in water treatment allows a portion of the influent water to avoid the treatment process, resulting in higher chloride concentrations in the final output compared to no bypass systems. Understanding chloride removal efficiency is crucial, as systems without bypass ensure comprehensive treatment and lower chloride levels, thereby meeting stricter discharge regulations. Selecting between chloride bypass and no bypass impacts the plant's ability to control chloride discharge, protect aquatic environments, and comply with environmental standards.

How Chloride Bypass Works: Process Overview

Chloride bypass operates by diverting chloride ions from the main water flow, preventing excessive chloride accumulation in treatment systems and reducing corrosion risks. The process typically involves a controlled bypass channel or membrane that selectively removes chloride compounds, enhancing water quality and protecting infrastructure. This method is crucial in managing saline water inputs and maintaining compliance with environmental regulations.

No Bypass Approach: Key Features and Methods

The No Bypass approach in chloride removal emphasizes direct treatment of water without diverting flow, utilizing methods such as advanced filtration, chemical precipitation, and ion exchange to reduce chloride concentrations effectively. This technique minimizes infrastructure complexity and operational costs by eliminating the need for bypass pipelines or auxiliary treatment units. Enhanced automation and real-time monitoring technologies ensure precise control of chloride levels, promoting environmental compliance and system efficiency.

Comparative Efficiency: Chloride Bypass vs. No Bypass

Chloride bypass systems improve corrosion control efficiency by selectively diverting chloride ions away from sensitive infrastructure, reducing material degradation compared to systems with no bypass. This targeted approach enhances longevity and lowers maintenance costs in industrial and water treatment applications. Your process benefits from increased operational reliability and reduced downtime when implementing chloride bypass over no bypass configurations.

Environmental Impact Assessment

Chloride bypass systems reduce the release of harmful chloride compounds into the environment by effectively diverting contaminated water during industrial processes, thereby minimizing soil and water pollution. No bypass methods often lead to higher concentrations of chlorides entering ecosystems, increasing the risk of toxic buildup and long-term environmental damage. Your choice of chloride bypass can significantly improve compliance with Environmental Impact Assessment regulations by lowering pollutant discharge levels.

Operational Costs and Long-term Savings

Chloride bypass systems reduce operational costs by minimizing corrosion and maintenance expenses associated with chloride buildup, extending the lifespan of equipment. Implementing a chloride bypass leads to long-term savings through decreased chemical consumption and reduced downtime for repairs. Your investment in a proper chloride bypass setup ensures more efficient resource use and sustained cost efficiency over time.

Maintenance and System Longevity

Chloride bypass systems reduce corrosion by diverting chloride ions away from critical components, significantly lowering maintenance frequency and extending system longevity. Without bypass, chloride accumulation accelerates metal degradation, leading to increased repairs and shorter equipment life. You can optimize your system's durability and reduce downtime by choosing chloride bypass technology.

Applications and Industry Suitability

Chloride bypass systems excel in industries such as water treatment, chemical manufacturing, and oil refining, where controlling chloride ion concentration is critical to prevent corrosion and equipment damage. In contrast, no bypass configurations are preferred in applications requiring minimal maintenance and straightforward flow systems, such as residential water filtration and food processing. Selecting between chloride bypass and no bypass depends on the operational environment's sensitivity to chloride levels and the industry-specific regulatory standards.

Choosing the Right Solution: Factors to Consider

Selecting between chloride bypass and no bypass requires evaluating factors such as water quality, system design, and operational cost. Chloride bypass systems effectively reduce corrosion potential in cooling towers by diverting chlorides, making them ideal for high-salinity environments. No bypass setups may suit low-chloride water sources but necessitate stringent monitoring to prevent scale and corrosion issues.

Chloride Bypass vs No Bypass Infographic

libmatt.com

libmatt.com