Direct firing systems deliver projectiles straight at a visible target, offering immediate impact and precision for close-range engagements. Indirect firing systems launch ammunition in an arcing trajectory to strike targets beyond line of sight, enhancing your ability to engage enemies from concealed or distant positions.

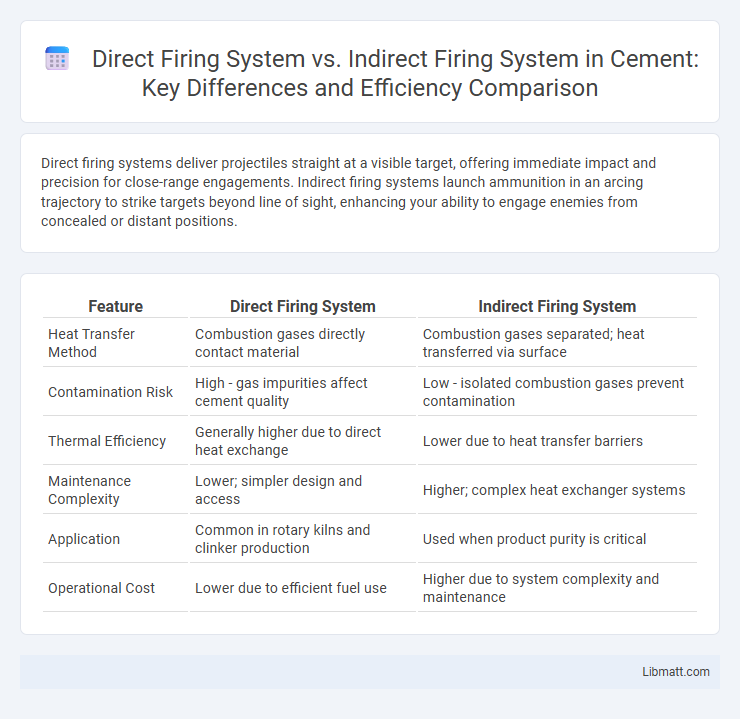

Table of Comparison

| Feature | Direct Firing System | Indirect Firing System |

|---|---|---|

| Heat Transfer Method | Combustion gases directly contact material | Combustion gases separated; heat transferred via surface |

| Contamination Risk | High - gas impurities affect cement quality | Low - isolated combustion gases prevent contamination |

| Thermal Efficiency | Generally higher due to direct heat exchange | Lower due to heat transfer barriers |

| Maintenance Complexity | Lower; simpler design and access | Higher; complex heat exchanger systems |

| Application | Common in rotary kilns and clinker production | Used when product purity is critical |

| Operational Cost | Lower due to efficient fuel use | Higher due to system complexity and maintenance |

Introduction to Firing Systems

Direct Firing Systems deliver heat through immediate contact between the fuel flame and the material, ensuring rapid temperature rise and precise control for processes like metal forging. Indirect Firing Systems transfer heat via a heat exchanger or heated air, preventing combustion gases from contacting the product, ideal for applications requiring contamination-free heating such as food processing. Understanding the operational differences is essential for selecting the proper firing system based on efficiency, product quality, and safety requirements.

What is a Direct Firing System?

A Direct Firing System launches projectiles directly at a target along a straight trajectory, ensuring precision in applications such as artillery and tank weaponry. Your targeting accuracy relies on a clear line of sight between the firing platform and the target without intermediary elements. This system contrasts with Indirect Firing Systems, which arc projectiles over obstacles using calculated angles and distances.

What is an Indirect Firing System?

An Indirect Firing System is a type of targeting method used primarily in artillery and missile operations where the weapon is aimed without direct line-of-sight to the target, relying on calculations, maps, and coordinates for accurate strike. Unlike Direct Firing Systems, which require visual confirmation, Indirect Firing Systems use advanced sensors, ballistic computers, and communication networks to engage targets obscured by terrain or distance. Understanding your weapon's firing system is crucial for optimizing strategic deployment and improving accuracy in complex combat scenarios.

Key Components of Direct Firing Systems

Key components of Direct Firing Systems include the flame sensor, burner assembly, and the control module that directly regulates the combustion process. The burner assembly typically consists of a gas valve, igniter, and fuel nozzle designed to deliver and ignite fuel within the combustion chamber. Flame sensors detect the presence of a stable flame to ensure safe operation, while the control module adjusts fuel flow and ignition timing for optimal combustion efficiency.

Key Components of Indirect Firing Systems

Indirect Firing Systems primarily consist of a mortar or howitzer, a fire control system, and a forward observer to calculate target coordinates. The fire control system integrates ballistic computers, communication devices, and sensors to accurately adjust firing angles for indirect target engagement. These components work together to enable precision strikes without direct line-of-sight to the target.

Comparison of Operating Principles

Direct firing systems operate by exposing the fuel directly to the combustion process, allowing immediate heat transfer to the target area, resulting in faster heating and higher energy efficiency. Indirect firing systems utilize a heat exchanger to transfer heat from the combustion gases to the heating medium, reducing contamination risks but typically lowering thermal efficiency due to heat loss during transfer. The choice between these systems depends on application requirements, where direct firing suits quick heat delivery and indirect firing ensures cleaner, controlled heating environments.

Efficiency and Performance: Direct vs Indirect

Direct firing systems provide superior thermal efficiency by delivering heat directly to the target surface, minimizing energy loss and enabling faster heating times. Indirect firing systems, while offering more controlled and uniform heat distribution, typically exhibit lower overall efficiency due to heat transfer through an intermediary medium. Performance in direct firing is enhanced for applications requiring rapid temperature changes, whereas indirect firing systems excel in processes demanding precise temperature control and consistency.

Safety Considerations in Both Systems

Direct Firing Systems pose higher risks of burns and accidental ignition due to the exposed flames, requiring strict safety protocols and protective barriers. Indirect Firing Systems enhance safety by containing flames within a combustion chamber, reducing the chance of accidental contact or fire spread, which is crucial in crowded or confined settings. Your choice should consider these safety differences to minimize hazards and comply with relevant safety standards.

Applications and Industrial Use Cases

Direct firing systems are primarily used in industrial heating processes such as furnaces, boilers, and kilns where immediate and intense heat is required, making them ideal for metal forging, glass manufacturing, and chemical processing. Indirect firing systems find applications in industries where clean heat is essential, including food processing, pharmaceuticals, and semiconductor manufacturing, by preventing contamination through indirect heat transfer methods. Both systems optimize energy usage depending on the need for direct flame contact or controlled, contaminant-free heat sources in various industrial environments.

Choosing the Right Firing System

Choosing the right firing system depends on the specific application and desired efficiency; direct firing systems deliver heat directly to the process, offering faster response and higher energy efficiency, while indirect firing systems use a heat exchanger, providing cleaner combustion and reducing contamination risks. Your selection should consider factors such as fuel type, maintenance requirements, and process sensitivity to combustion by-products to optimize performance. Proper evaluation of these parameters ensures the most effective and sustainable firing system for your operational needs.

Direct Firing System vs Indirect Firing System Infographic

libmatt.com

libmatt.com