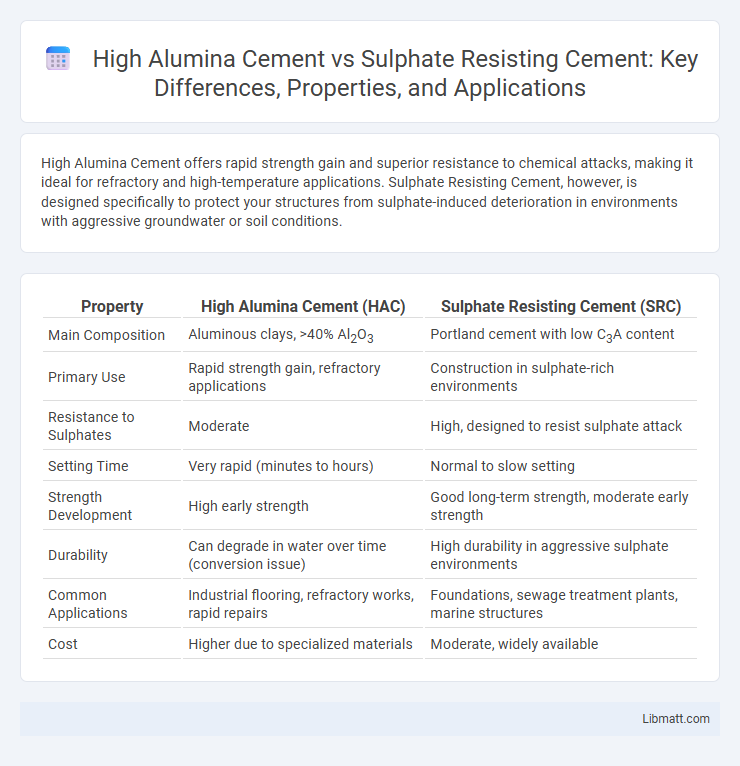

High Alumina Cement offers rapid strength gain and superior resistance to chemical attacks, making it ideal for refractory and high-temperature applications. Sulphate Resisting Cement, however, is designed specifically to protect your structures from sulphate-induced deterioration in environments with aggressive groundwater or soil conditions.

Table of Comparison

| Property | High Alumina Cement (HAC) | Sulphate Resisting Cement (SRC) |

|---|---|---|

| Main Composition | Aluminous clays, >40% Al2O3 | Portland cement with low C3A content |

| Primary Use | Rapid strength gain, refractory applications | Construction in sulphate-rich environments |

| Resistance to Sulphates | Moderate | High, designed to resist sulphate attack |

| Setting Time | Very rapid (minutes to hours) | Normal to slow setting |

| Strength Development | High early strength | Good long-term strength, moderate early strength |

| Durability | Can degrade in water over time (conversion issue) | High durability in aggressive sulphate environments |

| Common Applications | Industrial flooring, refractory works, rapid repairs | Foundations, sewage treatment plants, marine structures |

| Cost | Higher due to specialized materials | Moderate, widely available |

Introduction to High Alumina Cement (HAC) and Sulphate Resisting Cement (SRC)

High Alumina Cement (HAC) is a specialized cement known for its rapid strength development and exceptional resistance to high temperatures, making it ideal for refractory applications and aggressive chemical environments. Sulphate Resisting Cement (SRC) is formulated to provide enhanced durability against sulphate attack in soil and groundwater, making it suitable for structures exposed to harsh sulphate-rich conditions. Both cements play critical roles in construction projects requiring specific performance characteristics related to chemical resistance and environmental durability.

Composition and Chemical Properties

High Alumina Cement (HAC) primarily contains 40-80% alumina (Al2O3) with calcium aluminates, offering rapid strength development and resistance to high temperatures. Sulphate Resisting Cement (SRC) is formulated with a low C3A (tricalcium aluminate) content, typically less than 5%, to improve durability against sulphate attack in aggressive environments. The chemical stability of HAC arises from its high alumina content, while SRC's resistance is due to reduced reactive aluminates that minimize sulphate-induced expansion and deterioration.

Manufacturing Process Comparison

High Alumina Cement is produced by calcining a mixture of bauxite and limestone at temperatures around 1600degC, resulting in a cement rich in calcium aluminates with rapid hydration properties. Sulphate Resisting Cement involves blending ordinary Portland cement clinker with supplementary cementitious materials like fly ash or blast furnace slag, reducing tricalcium aluminate content to enhance sulphate resistance. The high temperature sintering in High Alumina Cement manufacturing contrasts with the grinding and blending process used in Sulphate Resisting Cement production, leading to differing chemical compositions and performance characteristics.

Key Physical Characteristics

High Alumina Cement exhibits rapid strength gain and high resistance to chemical attack due to its dense microstructure and alumina content, making it ideal for refractory and high-temperature applications. Sulphate Resisting Cement contains low C3A (tricalcium aluminate) content to minimize sulphate attack, enhancing durability in sulfate-rich environments like sewage and marine structures. Both cements offer specific physical properties tailored to aggressive environments, with HAC focusing on high strength and thermal resistance, while SRC emphasizes sulphate durability and long-term stability.

Strength Development and Performance

High Alumina Cement (HAC) exhibits rapid strength development, achieving high early strength within 24 hours, making it suitable for projects requiring quick setting and early load application. Sulphate Resisting Cement (SRC) develops strength more gradually but offers superior durability in aggressive environments by resisting sulfate attacks that can compromise concrete integrity. HAC may suffer strength loss over time due to conversion phenomena, while SRC maintains long-term performance in sulfate-rich soils and waters.

Resistance to Chemical Attacks

High Alumina Cement exhibits superior resistance to chemical attacks, particularly against aggressive sulfates, acids, and alkalis, making it ideal for harsh environments such as sewage treatment plants and chemical factories. Sulphate Resisting Cement is specifically designed to withstand sulfate-rich soils and waters, offering enhanced durability in sulfate-exposed construction but with less resistance to acidic conditions compared to High Alumina Cement. Your choice depends on the specific chemical exposure in your project, ensuring optimal protection and longevity.

Typical Applications and Usage Areas

High Alumina Cement is commonly used in refractory applications, rapid repair works, and environments requiring high early strength and resistance to chemical attack, such as sewage treatment plants and marine structures. Sulphate Resisting Cement is primarily utilized in foundations, basements, and concrete exposed to aggressive sulfate-bearing soils or groundwater to prevent sulphate-induced corrosion. Both cements serve specialized roles where durability against chemical degradation is critical in construction and infrastructure projects.

Durability and Longevity

High Alumina Cement offers exceptional durability in high-temperature and chemically aggressive environments due to its high alumina content, which enhances resistance to sulfate attack and rapid strength gain. Sulphate Resisting Cement is specifically formulated to withstand sulfate-rich soils and waters, providing long-term protection against expansion and cracking caused by sulfate interaction. Both cements ensure longevity in construction; High Alumina Cement excels in thermal stability and early strength, while Sulphate Resisting Cement is preferred for ensuring structural integrity in sulfate-exposed conditions.

Cost Comparison and Economic Factors

High Alumina Cement (HAC) generally has a higher initial cost than Sulphate Resisting Cement (SRC) due to its specialized manufacturing process and raw material requirements. However, HAC may offer economic benefits in environments requiring rapid strength gain or resistance to high temperatures, potentially reducing construction time and labor costs. SRC is often preferred for its cost-effectiveness in sulphate-rich environments, providing durable performance that minimizes long-term maintenance expenses.

Environmental Considerations and Sustainability

High Alumina Cement (HAC) exhibits rapid strength development but has a higher energy consumption and CO2 footprint due to its clinker production process, impacting sustainability negatively compared to Sulphate Resisting Cement (SRC). SRC is designed to withstand sulfate attacks, extending the lifespan of structures in aggressive environments, thereby reducing the need for frequent repairs and lowering long-term environmental impact. Lifecycle assessments show SRC offers better durability and resource efficiency, making it a more sustainable choice in sulfate-rich soils and marine conditions.

High Alumina Cement vs Sulphate Resisting Cement Infographic

libmatt.com

libmatt.com