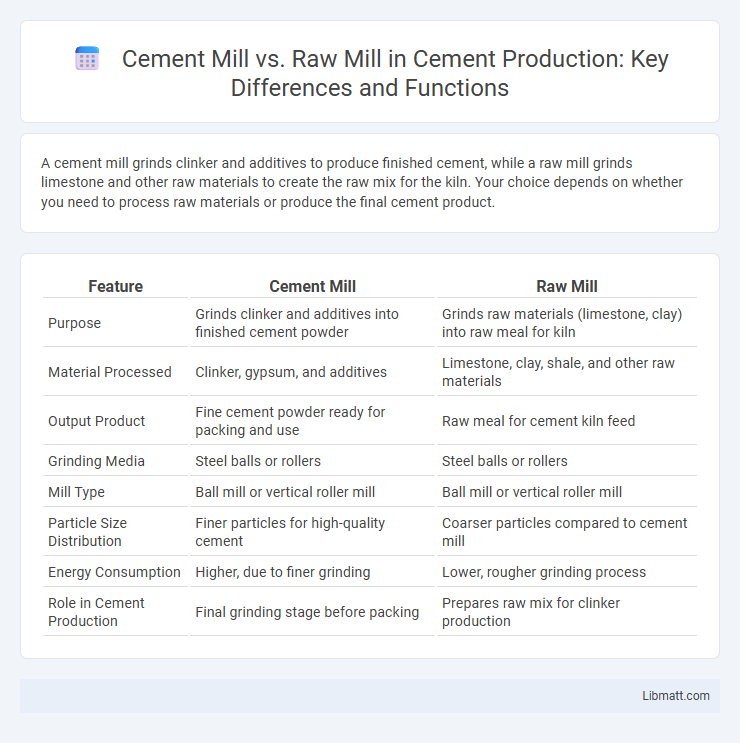

A cement mill grinds clinker and additives to produce finished cement, while a raw mill grinds limestone and other raw materials to create the raw mix for the kiln. Your choice depends on whether you need to process raw materials or produce the final cement product.

Table of Comparison

| Feature | Cement Mill | Raw Mill |

|---|---|---|

| Purpose | Grinds clinker and additives into finished cement powder | Grinds raw materials (limestone, clay) into raw meal for kiln |

| Material Processed | Clinker, gypsum, and additives | Limestone, clay, shale, and other raw materials |

| Output Product | Fine cement powder ready for packing and use | Raw meal for cement kiln feed |

| Grinding Media | Steel balls or rollers | Steel balls or rollers |

| Mill Type | Ball mill or vertical roller mill | Ball mill or vertical roller mill |

| Particle Size Distribution | Finer particles for high-quality cement | Coarser particles compared to cement mill |

| Energy Consumption | Higher, due to finer grinding | Lower, rougher grinding process |

| Role in Cement Production | Final grinding stage before packing | Prepares raw mix for clinker production |

Introduction to Cement Mill and Raw Mill

A cement mill is a vital grinding machine used in cement manufacturing to grind clinker into fine cement powder, ensuring appropriate particle size for hydration and strength development. A raw mill grinds raw materials such as limestone, clay, and other additives into a fine powder known as raw meal, which is then fed into the kiln for clinker production. Both mills use similar grinding principles, but their roles differ significantly in the cement production process, with the raw mill focusing on raw material preparation and the cement mill on final product grinding.

Key Functions of Cement Mill

Cement mills play a crucial role in grinding clinker into fine powder, transforming it into cement that can be used in construction. Unlike raw mills, which primarily grind raw materials for the kiln, cement mills ensure the final product meets required fineness and quality standards for concrete production. Your project depends on the precision and efficiency of the cement mill to achieve optimal durability and performance in building materials.

Primary Role of Raw Mill

The primary role of the raw mill is to grind raw materials such as limestone, clay, and sand into a fine powder called raw meal, which serves as the main input for the cement kiln. Unlike the cement mill, which grinds clinker into finished cement, the raw mill ensures the correct particle size and chemical composition necessary for clinker formation during the kiln process. Efficient operation of the raw mill directly affects the quality of the clinker and overall cement production efficiency.

Differences in Operating Principles

Cement mills grind clinker into fine powder using high-speed rotation and pressure to achieve a specific particle size for cement production. Raw mills, on the other hand, primarily grind raw materials like limestone and clay at slower speeds with a focus on preparing the raw meal for kiln processing. Your choice between them depends on the material being processed and the stage of production, as cement mills handle finished grinding, while raw mills prepare the feedstock for clinker formation.

Material Input and Output Comparison

Cement mills process clinker combined with gypsum and other additives into fine cement powder, producing a final product ready for construction use. Raw mills grind raw materials such as limestone, clay, and iron ore into raw meal as input for the kiln in cement production. Understanding the difference in material input and output between your cement mill and raw mill can optimize production efficiency and product quality.

Energy Consumption: Cement Mill vs Raw Mill

Cement mills typically consume more energy than raw mills due to the finer grinding required to produce cement, with energy consumption ranging between 30 to 50 kWh per ton compared to 20 to 30 kWh per ton for raw mills. Your plant's energy efficiency can be significantly improved by optimizing the cement mill operations, as it impacts overall production costs more heavily. Investing in advanced grinding technologies and utilizing roller mills or vertical mills can reduce power usage and enhance operational efficiency in both cement and raw milling processes.

Impact on Final Product Quality

Cement mills and raw mills play crucial roles in determining the quality of the final product by controlling particle size distribution and homogeneity. The cement mill ensures the clinker is ground to the desired fineness, directly impacting compressive strength and setting time of the cement. In contrast, the raw mill prepares raw material feed with uniform chemical composition, affecting the clinker's mineralogical properties and overall durability of the cement.

Maintenance Requirements and Challenges

Cement mills require higher maintenance due to abrasive wear from clinker and additives, demanding regular inspection of liners, rollers, and grinding media to prevent efficiency losses. Raw mills face challenges related to handling moisture and variable raw materials, necessitating frequent checks on drying systems and separator performance to avoid production disruptions. Both mills benefit from predictive maintenance technologies to optimize lifespan and minimize unplanned downtime.

Environmental Considerations in Each Mill

Cement mills generate significant dust and particulate emissions that require efficient filtration systems to minimize environmental impact, while raw mills typically produce fewer emissions due to the lower hardness of raw materials. Both mills consume substantial energy, with raw mills generally being more energy-efficient, contributing to reduced carbon footprint in cement production. Proper maintenance and use of advanced technologies in dust collection and energy management are essential to mitigate environmental concerns associated with both mill types.

Summary: Choosing the Right Mill for Cement Production

Cement mills are designed to grind clinker and other materials into fine cement powder, ensuring the right particle size for optimal hydration and strength, whereas raw mills primarily focus on grinding raw materials like limestone and clay to a suitable fineness for the kiln feed. Cement mills operate at higher energy levels and are built to achieve specific cement properties and consistency, while raw mills optimize the raw mix for clinker formation during the pyroprocessing stage. Selecting the appropriate mill depends on the production phase, desired product quality, energy efficiency, and equipment compatibility within the cement manufacturing process.

Cement mill vs Raw mill Infographic

libmatt.com

libmatt.com